- The Iron Army of China Construction Eighth Bureau shortens the air distance between Tibet and the world

China Construction Eighth Bureau "built" Tibet. On August 7, 2021, the T3 terminal of Lhasa Gonggar International Airport, which was constructed by the Eighth Engineering Bureau of China Construction Bureau, was officially put into operation. This is the highest trunk airport under construction in China.

From the beginning of the pile foundation construction at the end of 2017, the construction of the T3 terminal building took three and a half years. The project is large in scale, novel in shape, and complex in functions. During the process, the project team faced various challenges and accumulated rich experience in high-altitude airport construction.

Fight 12 gale

The design of the T3 terminal of Lhasa Gonggar International Airport fully integrates Tibetan regional culture and ethnic elements. The roof is shaped like lotus petals, with an abstract Tibetan golden roof, with a total area of 58,400 square meters.

The main part of the roof adopts a steel truss structure, and the panel part adopts aluminized zinc profiled steel plate. The structure is complicated and involves 9 structural levels. The project uses BIM technology throughout the entire roof construction process to strictly control the structural accuracy, ensuring the perfect presentation of the lotus roof.

There are many extreme weather in Tibet. In order to meet the test of strong wind and snow, the wind-resistant clip added on the roof of the terminal can resist the 12-level gale.

R&D and construction of high-strength self-compacting concrete

The T3 terminal of Lhasa Gonggar International Airport is 3570 meters above sea level. The plateau area lacks resources. According to the supply of local materials, the project implemented C50 self-compacting concrete configuration for the first time in Tibet, which solved the problem of concrete such as fly ash, mineral powder and silica fume. The problem of lack of admixtures.

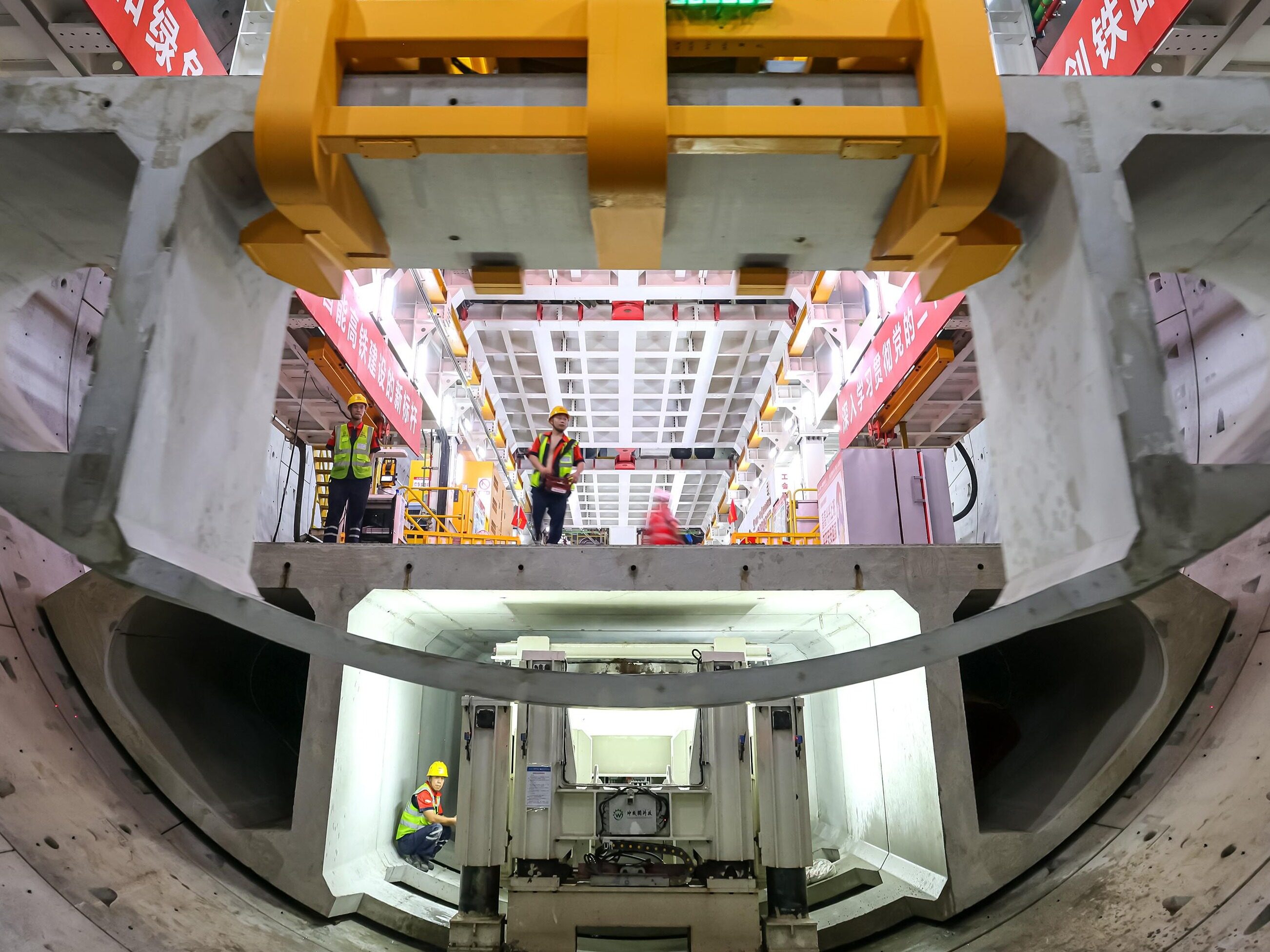

C50 self-compacting concrete was poured into the 12 steel columns supporting the lotus roof. In the process, the project changed the traditional concrete pouring technology and adopted special pumping jacking technology to avoid the loose concrete in the steel tube column in the plateau environment. Poor quality defects such as holes.

The T3 terminal of Lhasa Gonggar International Airport has undergone 3 winter treatments. The lowest temperature in winter in Tibet can reach -20℃, and the temperature difference between day and night is 18-20℃. In order to ensure the construction quality, the project adopts the greenhouse method, covering the concrete with rubber-plastic insulation cotton, and using the heater to heat the concrete components to ensure that the concrete strength reaches the curing temperature before the frost resistance critical strength.

10,000 tons of steel cast steel bars and iron bones

The T3 terminal of Lhasa Gonggar International Airport has a total construction area of about 88,000 square meters, of which the steel structure construction area is 56,000 square meters, using 10,000 tons of steel components, which is more than the weight of an Eiffel Tower.

The truss structure used in the construction of the steel structure of the project is complex. Among them, the shuttle-shaped column radial joint bearing lugs are 200 mm thick and have high stress requirements. The construction team and Tongji University carried out a 1:1 test to fully verify the construction safety and quality.

The project also set up 24 windproof shelters on site, and adopted technical measures such as pre-welding preheating and post-welding heat preservation to ensure welding quality in low temperature environments. Only the roof construction part, more than 200 workers lasted 4 months, and completed 3708 high altitudes. During the construction of welding joints, 200 tons of welding materials are used, and the length of welding wire can go around the earth's equator 1 circle.

Green construction protects the plateau environment

The Lhasa area has long hours of sunshine, and the high altitude makes the air thinner and less polluted. It is particularly "favored" by the sun and is also known as the "Sunshine City".

The project makes full use of local light conditions. Solar cells are installed on the 1,300-meter LED light strips on the surrounding road fence and the boom of the tower crane. The use of solar lighting on roads and fields reaches 90%. In the office and living areas, Two sets of large solar water heaters are also installed to use clean energy to protect the plateau ecology

With high altitude, high standards and higher quality, after the reconstruction and expansion project of Lhasa Gonggar Airport is put into operation, it will achieve the goal of 9 million passengers and 80,000 tons of cargo and mail in 2025. The Eighth Bureau of China Construction "built" Tibet, shortening the air distance with the world. Editor/Tian Zengpeng

Comment

Praise

Praise

Collect

Collect

Comment

Comment

Search

Search

Write something~