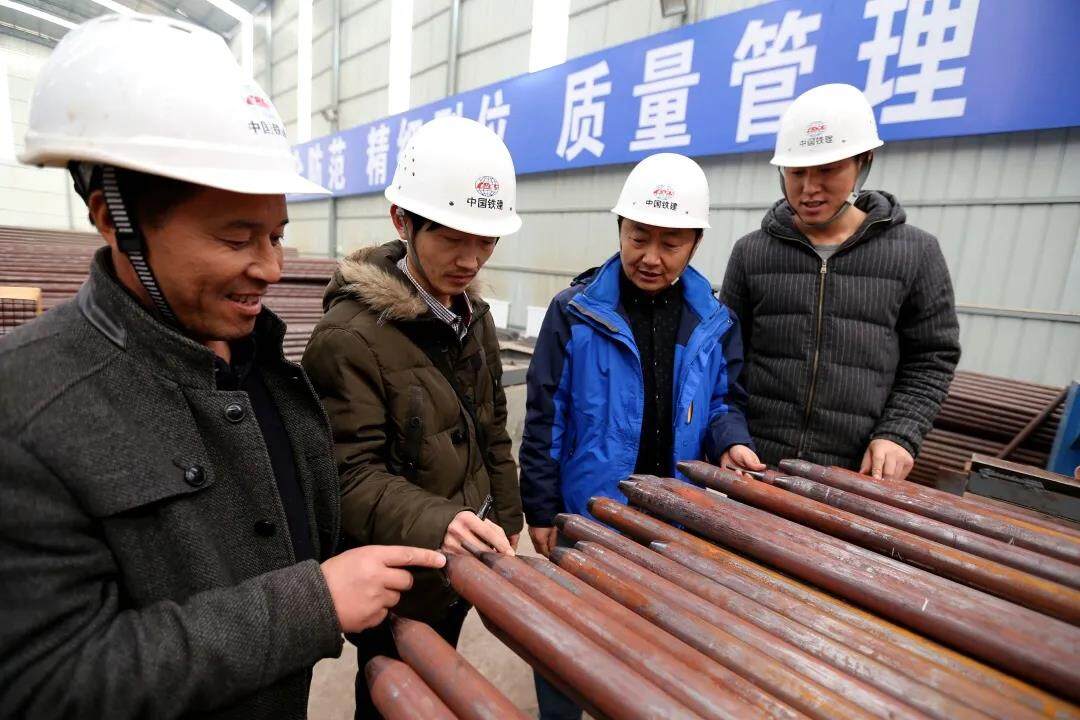

- Ma Xiaoli, Director of the Steel Structure Plant of the Third Engineering Co., Ltd. of China Railway Construction 21st Bureau Group

Ma Xiaoli, born in February 1971, a Communist Party member and winner of the National May 1st Labor Medal. The "Ma Xiaoli Model Worker Innovation Studio" named after him was awarded the honorary title of "Locomotive Model Worker and Craftsman Talent Innovation Studio" by the All-China Railway Federation in 2020.

With a strong Shaanxi Guanzhong accent and a dark complexion brought about by outdoor work all the year round, Ma Xiaoli has 44 national patent certificates. The individual won the National May 1st Labor Medal, and the team led by the team won the title of "Locomotive Model Worker and Craftsman Talent Innovation Studio"... From an ordinary laborer to a factory manager, the third engineering company of China Railway Construction 21st Bureau Group Steel Structure The story of the factory director Ma Xiaoli is like the plot in a TV series. Hard work, pragmatism, and innovation have made him a role model and role model in everyone's hearts.

Beginning laborers

After graduating from junior high school, Ma Xiaoli, who was born in poverty, came to a mechanic workshop as an apprentice and soon became a skilled electric welder. At the age of 18, he left his hometown to enter the construction industry, and then toured many places and started a part-time job career. Since then, with wisdom and hard work, he has "struggled" step by step with the power of scientific research to create his own road to success.

During a construction in 2001, the tunnel he was in had an 18-meter-long trumpet-shaped vent with a large head diameter of 14 meters and a small head diameter of 7 meters. If the lining trolley is specially made for this place, it will cost at least 600,000 yuan. The key is that it can only be used this time.

After finishing work, Ma Xiaoli went to the vent several times to measure dimensions, think about plans, make calculations, and draw sketches. He used a steel bar with a diameter of 12 mm as a mold. According to the diameter of the vent, he bends an arc every 50 cm, totaling 18. Then, he bent the I-beam according to the arc of the steel bar, connected them, and assembled the outer arc with steel formwork, and made a lining trolley by himself. The test results were good. This time, Ma Xiaoli made his first appearance.

"From then on, I became obsessed with designing and processing all kinds of construction machinery. What inspired me the most was an innovation during the 2008 Wenchuan earthquake." Ma Xiaoli recalled.

At that time, Ma Xiaoli was the squad leader of the Duwen Expressway Project of the Third Company of China Railway 21st Bureau Group. In that afternoon when the ground was shaking, the houses and engineering facilities on the construction site were instantly destroyed. Ma Xiaoli quickly calmed himself down, organized a count of the number of people, actively carried out rescue operations, and properly placed a number of wounded. However, the more difficult task is yet to come.

The Duwen Expressway Project Department is located in Longchi Town, Dujiangyan, only 3.6 kilometers away from the epicenter. After the earthquake, the Longxi Tunnel suffered severe damage, and the reconstruction after the disaster was regarded as an extremely dangerous project that was difficult to complete by many construction teams.

At that time, there was an urgent need for a wind gun excavation trolley at the tunnel face. Since it was a high gas tunnel, electric welding was not allowed in the tunnel. If the second lining is assembled outside the cave and the second lining construction is carried out inside the cave, the ultra-high and ultra-wide excavation trolley cannot pass.

Ma Xiaoli, who is proficient in electrical welding, came up with a solution: design and process the parts of the excavation trolley into bolt connections, and then assemble them on the face of the tunnel. The whole trolley shares more than 300 screws, which can be assembled in one day, which is safe and trouble-free.

A tunnel expert of the owner said: "I have been dealing with tunnels for more than 40 years, and this is the first time I have seen an excavation trolley that does not require welding."

Before the catastrophe, Ma Xiaoli was very happy and more energetic when he saw that his processing creation gave the project a substantial boost. Since then, with the company's technical and financial support, Ma Xiaoli adhered to the concept of "build whatever equipment is lacking in the project, and rebuild and optimize the equipment if it is not good", drawing, designing, and processing by himself. In just one year, he and his workers have overcome the unfavorable factors such as large earthquake damage, poor construction conditions, and less mechanical equipment, and achieved 14 innovative inventions, including a non-welded excavation trolley and a two-in-one spray anchor concrete automatic batching machine. , H-beam bending machine, multi-functional hoisting equipment and other practical construction technology achievements are called "Four Great Inventions" by colleagues around them, and are widely praised.

On May 12, 2009, Ma Xiaoli became the first person of China Railway Construction to be converted from a laborer to a full-time employee. He signed an open-term labor contract with the third company of China Railway 21st Bureau Group and officially became a member of China Railway Construction. In the same year, he also won the National May 1st Labor Medal.

Inventor rooted in the field

Ma Xiaoli keeps running, and the construction of Lan-Yu Railway, Lan-Xin High-speed Railway, Haoji Railway, Yanhuang Expressway, Guinan High-speed Railway and other engineering projects all have his footprints of innovation and creation. From equipment failure maintenance to mechanical modification and innovation, to brand-new inventions and creations, he insisted on being oriented by on-site needs, taking local materials, studying independently, and gradually growing into a grounded on-site inventor.

In the Lanyu Railway Project, the Taoshuping Tunnel that Ma Xiaoli participated in is one of the most complex and extremely high-risk tunnels on the Lanyu Railway. It is known as "rare in China and difficult in the world".

The construction period is in winter, and the mixing station needs heating and insulation to meet the construction needs. When Ma Xiaoli designed the mixing station, the mixer was sealed with three plywood, the chimney passed through, and the heat of the chimney was used to heat the mixer, so that the heat and heat of the heating water tank could be effectively used. The heat of the chimney raises the temperature in the mixer room to above 18 degrees Celsius, and the discharge port, water pump and pipeline of the mixer will not be frozen, and the working efficiency will be increased by more than 3 times.

In the construction of the Haoji Railway, Ma Xiaoli participated in the construction of the Junzi Tunnel, a key control project across the line. During the construction, it is difficult for vehicles in the tunnel to make a U-turn, so they can only drive in and come out upside down. "This way, the oily smoke is large, the safety is poor, and it also affects the construction progress." So Ma Xiaoli invented the research and development of the device to realize the vehicle U-turn in the tunnel.

Just talk and do it, Ma Xiaoli and other technicians discussed analysis, simulated demonstrations, and worked out research and development plans. In just over two months, he developed a U-turn device for the construction vehicle in the tunnel. The U-turn of the concrete tanker only takes 30 seconds. The equipment was very popular after it was put into use, and was praised by the drivers as a "turn-around artifact".

The Haoji Railway Steel Structure Processing Plant, headed by Ma Xiaoli, undertakes a total of 11,000 tons of steel products processing tasks. He started from improving product quality and improving production efficiency, conceiving and developing innovative equipment. Only 3 months after the construction of the Haoji Railway, Ma Xiaoli won the approval of the owner and the supervisor with his superb skills. His products are not only exempt from inspection, but also set as the "standard" for the entire line. In order to achieve a breakthrough in the quality of processed products, the brothers rushed to visit and learn from the experience. He innovatively developed various mechanical equipment, saving the project department more than 3 million yuan in equipment procurement costs.

In November 2015, China Railway 21st Bureau Group established the "Ma Xiaoli Model Worker Innovation Studio" named after Ma Xiaoli. In response to the construction difficulties of the two super-long tunnels on the Haoji Railway Xiaonanyuan and Junzi, the studio has successfully developed a tunnel escape pipeline self-propelled device, an automatic welding machine for steel joints, an automatic laying device for tunnel waterproof plates, a combined drill press for small pipes, and a folding rig for tunnel excavation. , Tunnel construction trolley rail self-propelled device, tunnel construction cantilever trolley, figure 8 bar bending machine, figure 8 bar automatic shaping welding machine, figure 8 bar automatic pressing device 10 kinds of 25 sets of mechanical equipment. These self-developed equipment played a huge role in construction.

In January 2017, "Ma Xiaoli Model Worker Innovation Studio" became the first batch of "China Railway Construction Model Worker (Advanced Staff) Innovation Studio". On November 26, 2020, the All-China Railway Federation awarded the studio the title of "Innovation Studio for Locomotive Model Workers and Craftsmen Talents".

At present, the studio has gathered 13 key technical R&D personnel. They closely followed the difficulties of construction and production, persisted in carrying out mass technological research, technological innovation and technological invention activities, which promoted the technological progress of enterprises, and formed various technological innovations and 47 national patents, including 43 utility model inventions and 4 invention patents. More than 20 achievements have been widely promoted and applied.

The leading goose

In 32 years, Ma Xiaoli achieved a magnificent turn from a laborer to a technical master. After 32 years of struggle, Ma Xiaoli has interpreted the work philosophy of "As long as we take root in the enterprise, there will be miracles if we have dreams".

For Ma Xiaoli, who only has a junior high school education, all this is not easy. But he was born with the stubborn temperament of a man in Guanzhong. He often used lights to fight at night, pondered hard, repeated exploration and modification of processing models, and drew piles of drawings until he was satisfied with the finished product. He took a long sigh of relief. Repeatedly staying up late and anxious, making him appear dark and thin, who was originally not tall.

In his daily work, Ma Xiaoli always carries a notebook with him, and writes it down whenever he finds a problem or has an inspiration. Now, he has accumulated several stacks of notebooks. He firmly believes that all R&D is to solve production problems, and the premise of solving problems is to discover problems.

Although it is half a hundred years old and has won many honors, Ma Xiaoli still sticks to the front line of construction. He said: "Only at the construction site can we find problems and find the direction of innovation."

Because of the long-term adherence to the front line, Ma Xiaoli understands the difficulties of on-site workers, and clearly knows that during the construction process, some equipment has the problems of low reuse rate and poor environmental performance. The two-in-one spray anchor concrete automatic batching machine, H-beam bending machine, and multi-functional hoisting equipment developed by him are mostly processed with waste steel. The cost is very low, but it is very practical in construction, which greatly reduces the labor intensity of workers.

After the establishment of the studio, Ma Xiaoli's innovation is no longer alone. With the joining of batch after batch of young people, the whole team is full of vigor and vitality.

In fact, in order to add motivation to his innovative practice, Ma Xiaoli has been actively participating in various trainings and cherishes the opportunity to learn very much. In recent years, he has obtained a college degree in power system automation from Xi'an Jiaotong University, and is currently continuing his undergraduate studies. During the epidemic in early 2020, Ma Xiaoli, who was rarely free, learned to use computers with the help of his nephew who majored in computer science. In the past, he used hand-drawn drawings. Now, he has learned to draw design drawings with a computer.

For the future, Ma Xiaoli has a clear plan. He hopes that more young technicians will join the studio to further promote the transformation of patented achievements, so that the new technology can better serve the actual construction site.

Obtaining 44 national patents in 32 years, Ma Xiaoli's exploration in innovation and improvement in practice demonstrates the spirit of industrial workers in the new era. He is hardworking, pragmatic, and innovative, just like a light that inspires us to forge ahead on a new journey. Editor/He Yuting

Comment

Praise

Praise

Collect

Collect

Comment

Comment

Search

Search

Write something~