- Nanchang Mining Machinery's sophisticated equipment appeared at the Guangzhou Sand and Stone Exhibition

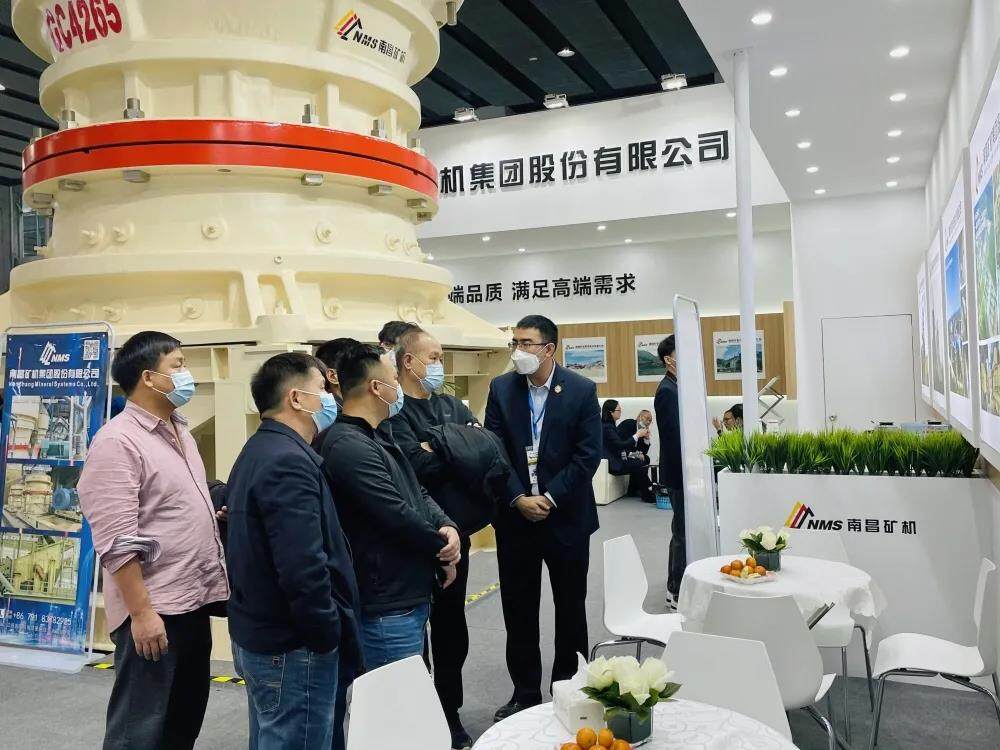

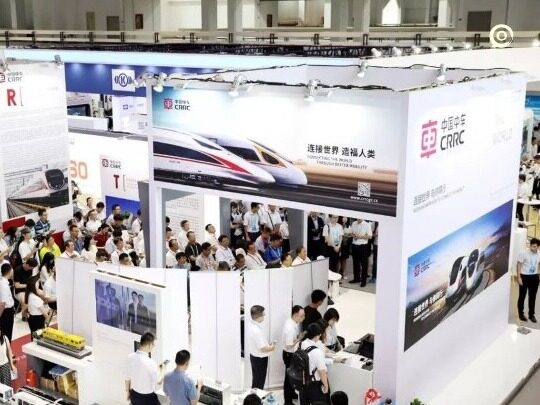

On December 4, 2021, the 7th Guangzhou Sandstone and Tailings and Construction Waste Disposal Technology and Equipment Exhibition (hereinafter referred to as "Guangzhou Sandstone Exhibition") opened at the China Import and Export Fair Complex in Guangzhou. Nanchang Mining Machinery Group Co., Ltd. (hereinafter referred to as "Nanchang Mining Machinery") was invited to participate in the exhibition.

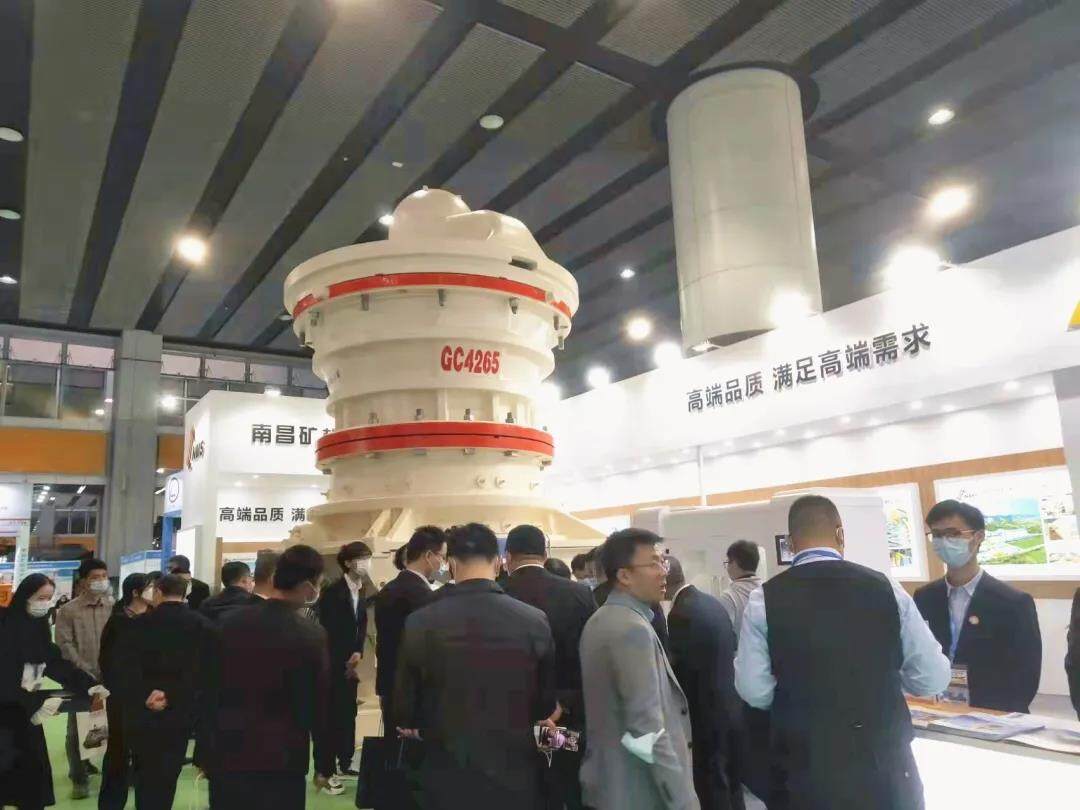

The Guangzhou Sand and Stone Exhibition is the most influential exhibition of sand, gravel and construction waste and equipment in South China. Many excellent sand and aggregate equipment companies from home and abroad gather together, representing the new technology at the forefront of the current sand and aggregate industry. , New ideas and new equipment compete on the same stage and shine. At booth T10, Hall 2.1, Area A of the Exhibition Center, the large-scale GC4265 gyratory crusher, rock and mine crushing power index testing machine, and rock and mine abrasion index testing machine independently developed by Nanchang Mining Machinery have attracted popularity for the booth with their unique charm.

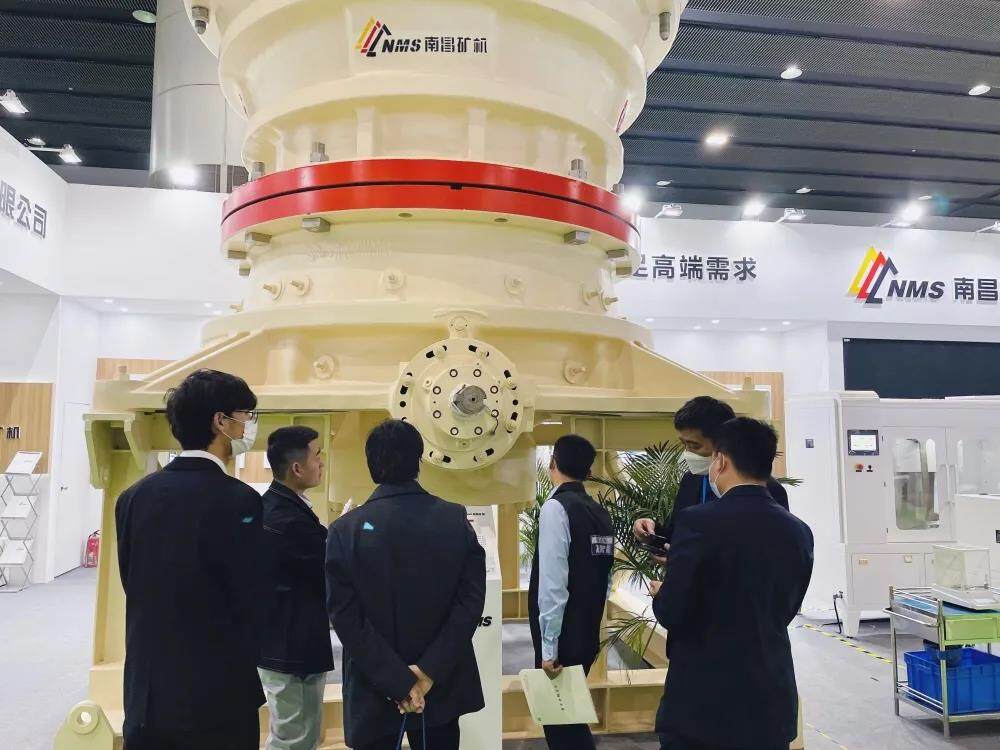

High output: big circle for big projects

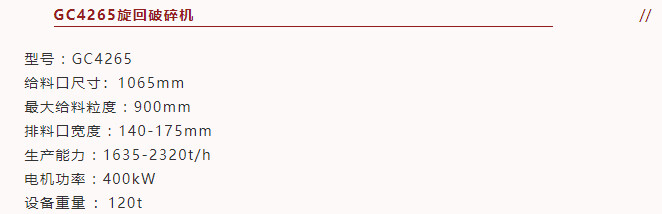

The GC4265 gyratory crusher of Nanchang Mining Machine applies international advanced crushing technology and high-efficiency and energy-saving design concepts. It has the characteristics of large processing capacity, high crushing efficiency, large crushing ratio, uniform product size, low energy consumption, and uniform wear in the crushing cavity. It is suitable for use under larger production scale conditions.

The equipment adopts the latest hydraulic balance cylinder protection system, intelligent electrical control system and touch screen display system, which can automatically adjust the working status, effectively realize the integration of mechanical, electrical, and hydraulic, with a high degree of automation, which significantly improves the production efficiency and operational reliability of the equipment , It is an ideal product for large-scale primary crushers.

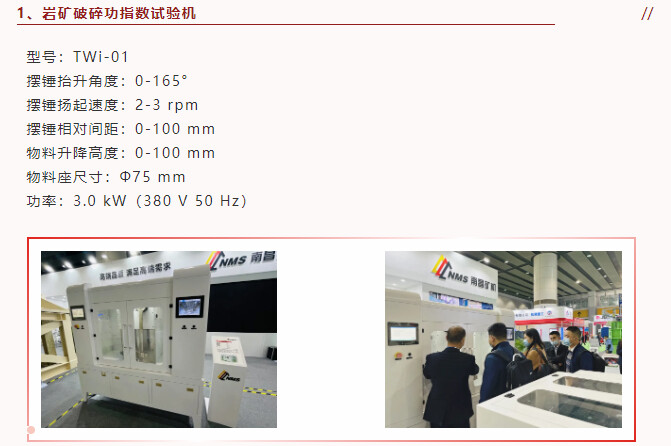

Strong assistance: the first appearance of the test machine, assisting equipment selection

The crushability and abrasiveness of the material are the decisive factors when selecting the crushing equipment, that is, the crusher is selected by measuring the crushing work index (Wi) and abrasion index (Ai) of the material. At present, some domestic research institutes use manual mechanical measuring equipment, and the test results need to be calculated separately by professionals, which require high professional ability and are not suitable for popularization.

In order to achieve more precise and efficient selection of crushing equipment and better serve customers, Nanchang Mining Machinery has independently developed rock and mineral processing attribute testing machine products-rock and mineral crushing work index testing machine and rock and mineral abrasion index testing machine. This is also the first time that two test machines have appeared in front of the public.

The testing machine uses the scientific and technological achievements of contemporary electromechanical integration and adopts the PLC controller to control the test process. The operator only needs to input the relevant parameters on the screen, and the equipment will automatically run. After calculation by the self-developed test software, the results will be directly displayed on the screen. high degree of automation. The whole process of the test is monitored and recorded, and the test data and results can be exported through the USB port, which is easy to operate. The testing machine developed by Nanchang Mining Machinery requires low professional knowledge of operators, high work efficiency, and completely eliminates the error probability of manual data recording. It is suitable for various manufacturers and scientific research institutes in the rock crushing industry, and is suitable for large-scale promotion and application.

◎The lifting angle of the pendulum is automatically completed by the servo motor under the control of the PLC, and it is automatically lifted within the range of 0-165 degrees, and the angle control is accurate.

◎Using self-developed pendulum impact test software.

◎After the pendulum reaches the set lifting angle, the PLC controlled clutch will be powered off at the same time, and the two pendulums will fall freely synchronously, and the synchronization degree is accurate to the millisecond level.

◎Fully enclosed protective cover with steel sample is used to prevent splashing of the sample and hurt people with high safety performance.

◎The pendulum adopts a replaceable design to reduce the cost of equipment use.

◎Experiment record data, results and test monitoring video (pictures) can all be exported via USB.

◎The test process is controlled by the PLC controller, and the patented deceleration transmission structure is adopted. The speed of the rotating shaft and the rotating drum are adjusted by the frequency conversion speed-regulating motor, which can realize the concentric, same direction and different speed rotation of the rotating shaft and the rotating drum.

◎It can simulate the abrasion degree of metal specimens under general and specific conditions.

◎The weight data can be processed by itself. The electronic balance is connected to the PLC through a serial interface, and the weighing data is transmitted to the PLC for automatic calculation.

◎The inner cavity of the drum adopts replaceable wear-resistant liner, which effectively prolongs the service life of the drum.

◎The running parameters, running time, weighing value, and test results can be displayed on the screen, and the test data can be downloaded through the USB port. Editor/Sang Xiaomei

Wonderful moments of the exhibition

Comment

Praise

Praise

Collect

Collect

Comment

Comment

Search

Search

Write something~