- In order to further develop the market and expand and optimize the product spectrum, Sunward will develop new products in the future.

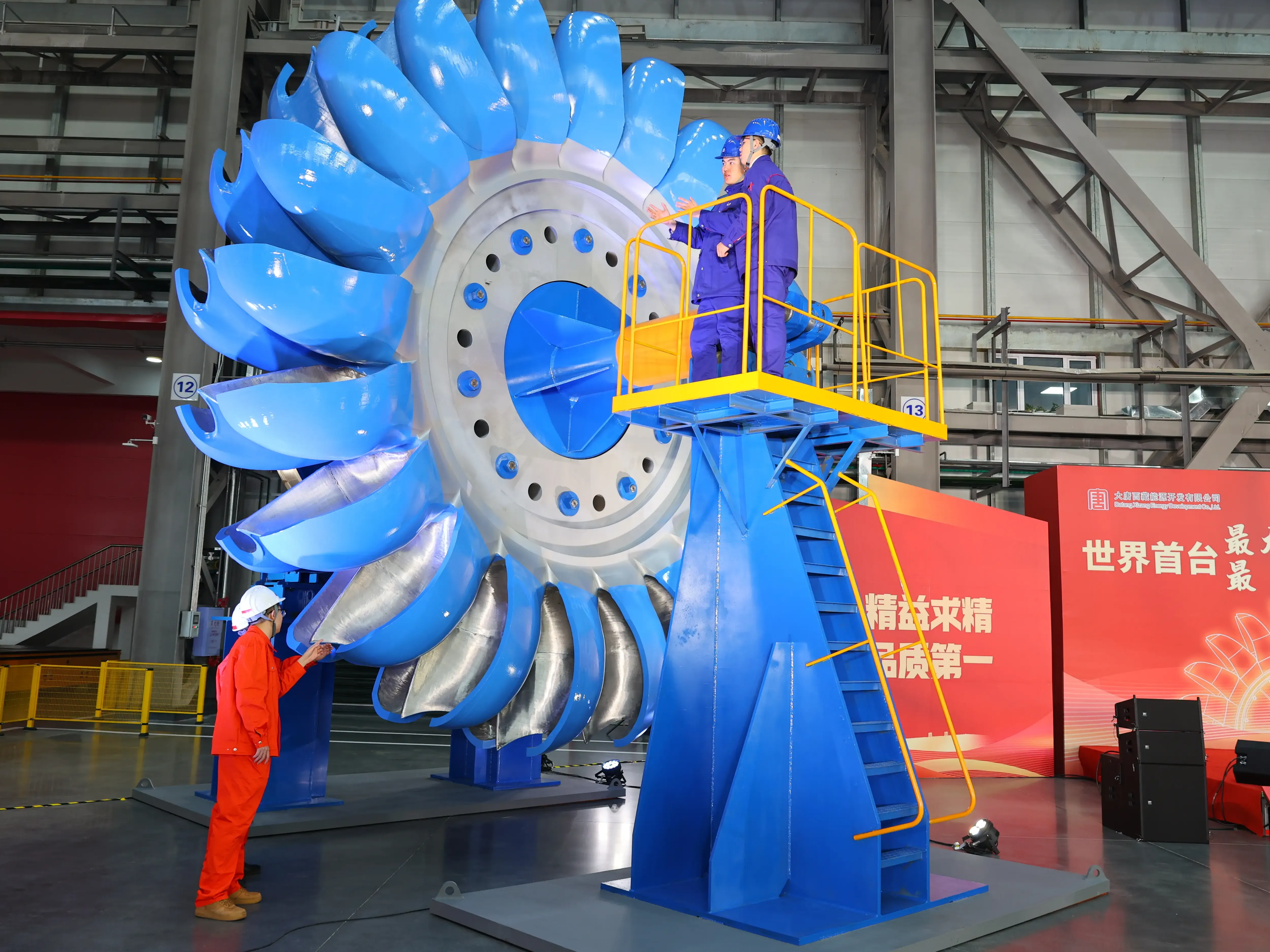

The maximum groove forming depth is 120 meters, the groove forming accuracy is 1/1000, the use cost is reduced by more than 60%, and the service life of the mud pipe is increased by more than 50%... On January 7, 2022, Sunward Intelligent's first double-wheel groove milling Machine - SWHC120 made a wonderful appearance at the global launch of underground engineering equipment!

Thanks to Sunward's profound technical accumulation and intelligent manufacturing capabilities in the field of underground engineering equipment, the SWHC120 double-wheel slot milling machine is designed in accordance with the EN16228 European safety standard, with higher product stability, intelligence, high precision, and high efficiency. A number of key core technologies were affirmed.

Intelligent integration, more efficient construction

SWHC120 double-wheel slot milling machine adopts full electronic control platform technology and integrates Shanhe Xiangyun construction management platform, which solves the problem that the current construction equipment and construction management cannot be intelligently integrated. At the same time, the equipment can realize functions such as unmanned operation, 5G remote control, real-time online fault diagnosis, automatic positioning, and real-time display of construction data. It can automatically adjust the speed and pressure according to different geological conditions to improve construction efficiency. At present, the intelligent level of products ranks in the forefront of the field of pile machinery.

It is understood that the fully electronic control platform technology is an important achievement of the "pioneering innovation" of Professor He Qinghua, the founder of Sunward Intelligent. The industry's first 5G intelligent rotary drilling rig launched based on this platform technology leads the intelligent upgrade of the industry's products.

Meet the construction depth requirements and lower the cost of use

In order to meet the construction depth requirements, the equipment is equipped with a 140-meter-long slag discharge pipe, which is wound on the reel device layer by layer. The R&D team of SWHC120 double-wheel slot milling machine successfully overcomes the automatic swing technology, adjusts the yaw angle of the reel in real time according to the construction depth, solves the problem of mutual extrusion and wear of the slag discharge pipe during the winding process, and improves the use of the slag discharge pipe More than 50% of the time, reducing the cost of use of the product.

Reliable and more durable, extending service life

In order to prevent the mud from entering the reducer, thereby reducing its service life, a seal is required to prevent the mud from entering the reducer. During ultra-deep underground construction, the sealing ring cannot withstand excessive pressure, which will cause it to be easily damaged, causing mud to enter the reducer and reducing the life of the equipment.

In order to solve this problem, the R&D team of SWHC120 double-wheel slot milling machine successfully overcome the pressure automatic compensation technology. When the external pressure of the reducer increases, the internal pressure of the reducer also increases accordingly, so that the internal and external pressures of the seal ring are basically the same, thus ensuring The reliable use of the sealing ring improves the service life of the reducer.

Heavy-duty chassis for more convenient transportation

In addition to ensuring the efficient operation of equipment, how to solve the problem of super-large machinery transportation is also a recognized problem worldwide. To this end, Sunward Intelligent has developed a heavy-duty chassis with a driving force of more than 100 tons and a transport width of 3.7 meters after retraction, which can better meet the requirements of domestic transportation regulations, reduce the transportation cost of super-large products, and improve the convenience of transportation.

In order to further develop domestic and international markets, expand and optimize the product spectrum, Sunward Intelligent will develop SWHC160 double-wheel slot milling machine, SWHC120E double-wheel slot milling machine, etc., and make Sunward's serialized double-wheel slot milling machine a "star product". Strive to achieve the top three market share. In the future, Sunward will continue to adhere to the original intention of "creating value for customers", provide customers with a full range of services for the entire life cycle of construction machinery, and contribute to the globalization of Chinese brands.Editor/Ma Xue

Comment

Praise

Praise

Collect

Collect

Comment

Comment

Search

Search

Write something~