- After the completion of the Han to Wei project, it can provide production and domestic water for 14.11 million people

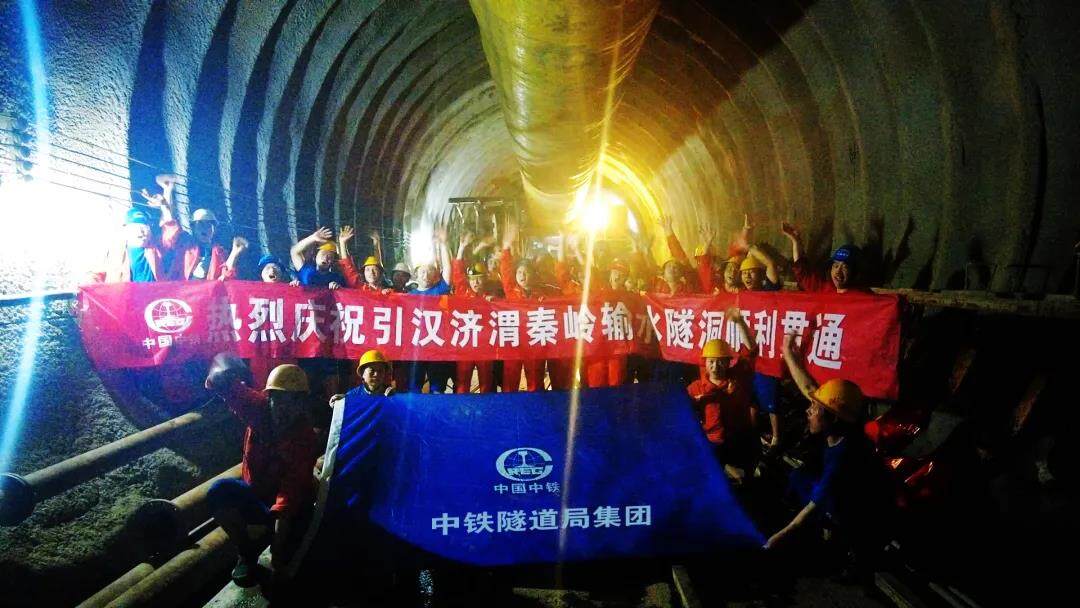

On February 22, 2022, the Qinling Water Conveying Tunnel, a key line of the Han-Ji-Wei project with a total length of 98.3 kilometers, was fully completed. The Qinling Water Transmission Tunnel is the first time in human history to cross the Qinling Mountains from the bottom. The water resources in the Han River Basin in southern Shaanxi will be introduced into the Guanzhong area through the Qinling Tunnel, which is the Shaanxi version of the South-to-North Water Diversion.

How difficult is the Qinling water tunnel

The Lingnan TBM excavation section of the Qinling Tunnel undertaken by China Railway Tunnel Bureau Group has the outstanding characteristics of "three highs, two strong and one long", namely high surrounding rock strength, high quartz content, high temperature and humidity, strong rock burst, strong water inrush, long-distance single-head construction It is the "hard bone" with the most rock bursts, the highest rock strength and the most difficult construction in the whole line of the Han-Ji-Wei project.

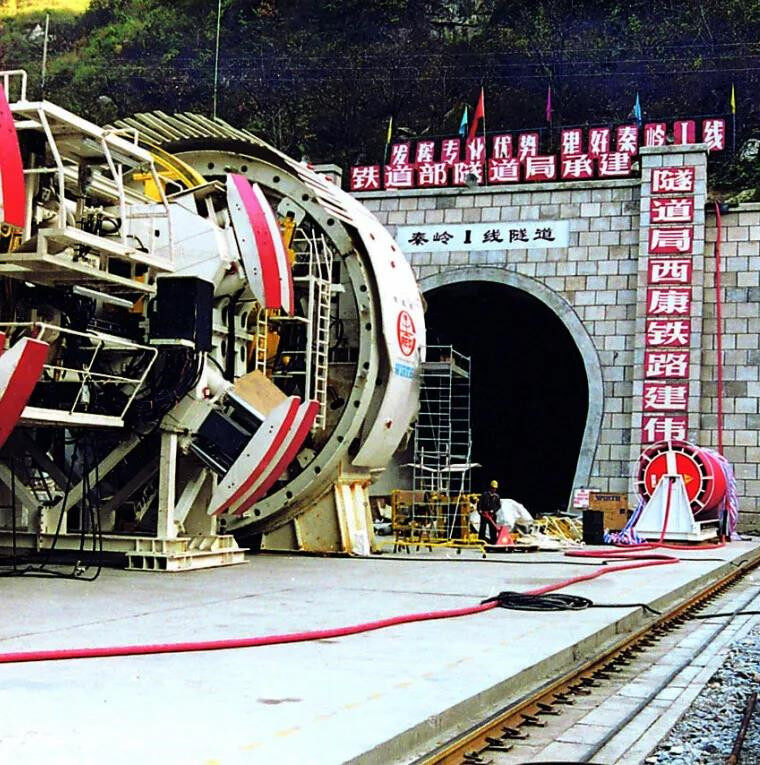

The Lingnan TBM excavation section of the Qinling Tunnel is located deep in the mountains of Ningshan County, Shaanxi Province. The construction includes a main tunnel with a length of 18.27 kilometers and a branch tunnel of No. 4 with a length of 5.82 kilometers, with a maximum buried depth of 2012 meters. Among them, the main hole is constructed by an open hard rock boring machine (TBM) with a diameter of 8.02 meters, and the slag is discharged by a continuous belt conveyor. In order to solve the problems of long-distance slag removal, ventilation and transportation of TBM in the second tunneling section of TBM, China Railway Tunnel Bureau Group adopted the combination of "TBM + drilling and blasting method", and built the inclined shaft of No. 4 branch tunnel as the connection section between the TBM maintenance hole and the main tunnel. Construction open work face.

From the start of construction to the completion, the Lingnan TBM excavation section of the Qinling Tunnel has always been advancing in a difficult environment intertwined with extremely complex geological conditions such as strong rock bursts, high hard rocks, inrush water, high temperature and humidity.

The Qinling Tunnel is buried at a depth of 1300-2012 meters, with a ground stress of more than 60 MPa, and the rock burst section accounts for 70% of the total construction length. During the excavation process, a total of 2056 rock bursts occurred in the Lingnan TBM excavation section, affecting a length of 8586.8 meters, including 4973.9 meters of strong rock bursts. Rock bursts and ejected rocks threaten the safety of operators and damage mechanical equipment and support systems. Operators have to wear helmets and protective clothing in a high temperature and humidity environment with a relative humidity of 90% and a body surface temperature of 40°C. Risking your life to clean up rock bursts.

The stratum dominated by quartzite, granite and diorite is the "natural enemy" of TBM excavation. The average compressive strength of the rock is 194 MPa, the highest is 317 MPa, and the quartz content exceeds 65%. High rock strength, high wear resistance, tool consumption of 0.7 pieces/m, extremely low driving speed and great tool consumption are the core issues that affect the rapid tunneling of TBM.

Since the TBM trial excavation, there have been 9 large concentrated water inflows in the tunnel, especially on February 28, 2016, the water inrush at a single point of the tunnel face exceeded 20,000 m3/d, and the maximum water inflow in the excavated section was 46,000 m3/d. d. To reach 3.76 times the design maximum water inflow of the bidding section, the China Railway Tunnel Bureau organized a rescue commando of 1,000 people, which took 75 days to successfully escape.

How important is it to attract Han to Wei

Since the 1980s and 1990s, due to the combined effects of climate change, economic development, population growth and other factors, the Guanzhong urban agglomeration has suffered from "water shortage". Shaanxi spans the two major river basins of the Yellow River and the Yangtze River, but the distribution of water resources is extremely uneven. South of Qinling Mountains belongs to the Yangtze River Basin, with abundant water sources, accounting for 71% of the province's total water resources; to the north of Qinling Mountains is the Yellow River Basin, where cities, factories and populations are densely populated, but only account for 29% of the province's total water resources. The contradiction of resource shortage has become an important factor restricting the economic and social development of Shaanxi Province.

The Han-to-Wei River Diversion Project is one of the ten landmark projects among the 172 major water conservancy projects requested by the State Council to accelerate construction during the 13th Five-Year Plan period. While solving the near-term water shortage problem in Guanzhong, the project will also be an important prerequisite for solving the water demand of the energy and chemical bases in northern Shaanxi in the near and mid-term, and a key project to realize the optimal allocation of water resources in the province.

Diverting the Han River to the Wei River spans the two major river basins of the Yellow River and the Yangtze River, and crosses the Qinling Mountains. It is divided into two parts: water transfer and water distribution. The water transfer project consists of three parts: the Jinjinxia Water Control Project, the Sanhekou Water Control Project and the Qinling Water Conveyance Tunnel. The water transmission and distribution project consists of the Huangchigou water distribution hub, the north-south trunk line and 23 branch lines. Among them, the Qinling Water Conveying Tunnel broke the barrier of the geographical dividing line between the north and the south of China, and realized the hand-in-hand of the Yangtze River and the Yellow River.

After the completion of the Han-to-Wei River diversion project, about 1.5 billion cubic meters of Han River water will be continuously imported into the Guanzhong area of Shaanxi through the Qinling Water Transfer Tunnel every year, which can meet the requirements of 4 key cities of Xi'an, Xianyang, Weinan and Yangling, and 5 of the Xixian New Area. 11 new cities, 11 county-level cities such as Xingping, Wugong, Sanyuan, and Weibei Industrial Zone, provide 14.11 million people with water for production and domestic use. For optimizing the allocation of water resources in Shaanxi Province, coordinating water use in Guanzhong and northern Shaanxi, and improving the national water supply It plays an important role in maintaining the ecological environment of the Weihe River Basin and supporting Shaanxi Province's economic catch-up and development.

Why China Railway Tunnel Bureau

Wang Sijing, an academician of the Chinese Academy of Engineering, sighed during the investigation on the TBM face of the Qinling Tunnel: "The Qinling Water Conveyance Tunnel Project is excavating in a super-long tunnel, and encountering hard rock, rock burst, and water inrush disasters are all huge difficulties. The superposition of these various geology is rare in China, far beyond the European Alps, and after the project is completed, the world will re-understand the geological structure of the Qinling Mountains.”

The construction of the Han-Wei-Qinling water conveyance tunnel took 13 years. China Railway Tunnel Bureau faced the challenge of extreme geological environment, promoted the construction technology of China's long TBM tunnel to a new level, and made the industry re-understand the professional strength of China Railway Tunnel Bureau. .

China Railway Tunnel Bureau's project department of the southern section of the Han-Ji-Wei Qinling Tunnel took the management of TBM equipment as the leader, and carried out the technical research on excavation under extreme geological conditions. A series of successful experiences have been accumulated in technical problems such as transportation, ventilation, long-distance super-hard rock formation, water inrush control, and long-distance measurement accuracy control of complex terrain in mountainous areas.

The project has obtained 3 invention patents and 2 utility model patents, and is the author of "TBM Card Machine Removal and Efficient Excavation" focusing on one, "Deep Buried Tunnel TBM Reverse Slope Excavation Inrush Water Treatment Construction Method", "Drilling and Explosion Tunnel Rock Burst Section" "Safe and Fast Construction Method" was rated as the construction method in Henan Province, "Construction Method of Open TBM Safely Passing Through Rock Burst Sections, Construction Method of High-pressure Water-rich Tunnel, Hard Rock Crack Formation, Radial Grouting Construction Method", "High Abrasion Deeply Buried Hard Rock Formation TBM Construction Method" "Construction Method" passed the China Railway Construction Method, and participated in the completion of the "Rockburst Early Warning and Prevention and Control of Han-Jiwei Tunnel Construction" won the "Twelfth China Rock Mechanics and Engineering Society Science and Technology Award (Science and Technology Progress Award) First Prize, " "Research on Tool Wear in Highly Abrasive Deep Buried Strata" won the first prize of the National Railway Group Science and Technology Progress Award, and participated in a number of long tunnel construction technology scientific research projects such as "Large deformation of surrounding rock and rockburst prediction and prevention technology for large buried deep tunnels" Research, the project department won the "National Youth Civilization" and many other honors.

Since the first introduction of hard rock boring machines (TBM) in China in the 1990s to build the Qinling Tunnel of Xikang Railway, China Railway Tunnel Bureau has led China's tunnel construction technology into the era of shield/TBM. TBM is widely used in large-scale water diversion projects, Long tunnels (lanes) such as tunnels through mountains and deep tunnels in coal mines are under construction. Especially in terms of hydraulic tunnels, China Railway Tunnel Bureau in Liaoning Dahuofang water conveyance tunnel, Qinghai diversion to Dajihuang project, Jilin water supply project to Song, Gansu to Tao water supply, Shaanxi to Hongji stone project, Inner Mongolia to Chuo to Liaoning During the construction of key and difficult hydraulic tunnel projects such as the project, the Pearl River Delta water resources allocation project, and the water diversion in the middle of Yunnan, it has undertaken many construction tasks of urgent, dangerous and heavy bidding sections, creating and maintaining a world record of 1,868 meters of monthly excavation and a single-day excavation. The national record of 101.12 meters has made important contributions to the balanced supply of regional water resources, economic and social development, and improvement of people's livelihood and well-being. Editor/He Yuting

Comment

Praise

Praise

Collect

Collect

Comment

Comment

Search

Search

Write something~