- Sunward will continue to give full play to its leading innovation advantages and keep up with the needs of national development

Recently, the Xixiang Station of the Guangzhou-Dongguan-Shenzhen Intercity Railway in Guangdong Province is undergoing intense and busy pile foundation construction. Standing on the project site, you can see a "green mountain and river" as far as the eye can see. It is reported that more than 10 pieces of equipment participating in the foundation construction of Xixiang Station's pile construction are all from Sunward, which shows the high recognition of Sunward's brand and equipment by customers.

Major project with many challenges

It is understood that the construction of the Shenzhen Baoan International Airport to Qianhai section of the Guangzhou-Dongguan-Shenzhen Intercity Railway will officially start in June 2021, with a total length of 15.2 kilometers. With an investment of 11.9 billion yuan, it is planned to be completed in 2025.

The Xixiang Station under construction is all occlusal piles and supporting piles. Since the construction site is located on the main road in the urban area, and both sides are residential areas, this puts forward higher requirements for the environmental protection and noise resistance of the equipment and construction. How to carry out pile foundation construction efficiently, accurately and environmentally has also become a prerequisite to ensure the smooth development of the project.

In order to realize the "one-hour economic circle" of the intercity transportation between Guangzhou, Dongguan and Shenzhen as soon as possible, the construction of the pile foundation of Xixiang Station is not only difficult, but also needs to face the challenges of tight project schedule and short construction time, which will affect the efficiency and stability of equipment construction. presented a great test.

How to solve the pollution caused by noise and dust during construction? How to solve the problem of low efficiency of rock formation construction? How to make more efficient use of construction time? This is the question that the person in charge of Hunan Yuteng Foundation Engineering Co., Ltd. has been thinking about since he received this project. The depth of the enclosure structure into the rock is relatively large, and the traditional rotary drilling construction can no longer meet the construction requirements of the project. When the person in charge was distressed, a friend recommended Sunward Intelligent to him.

Customized complete solutions solve customers' difficulties

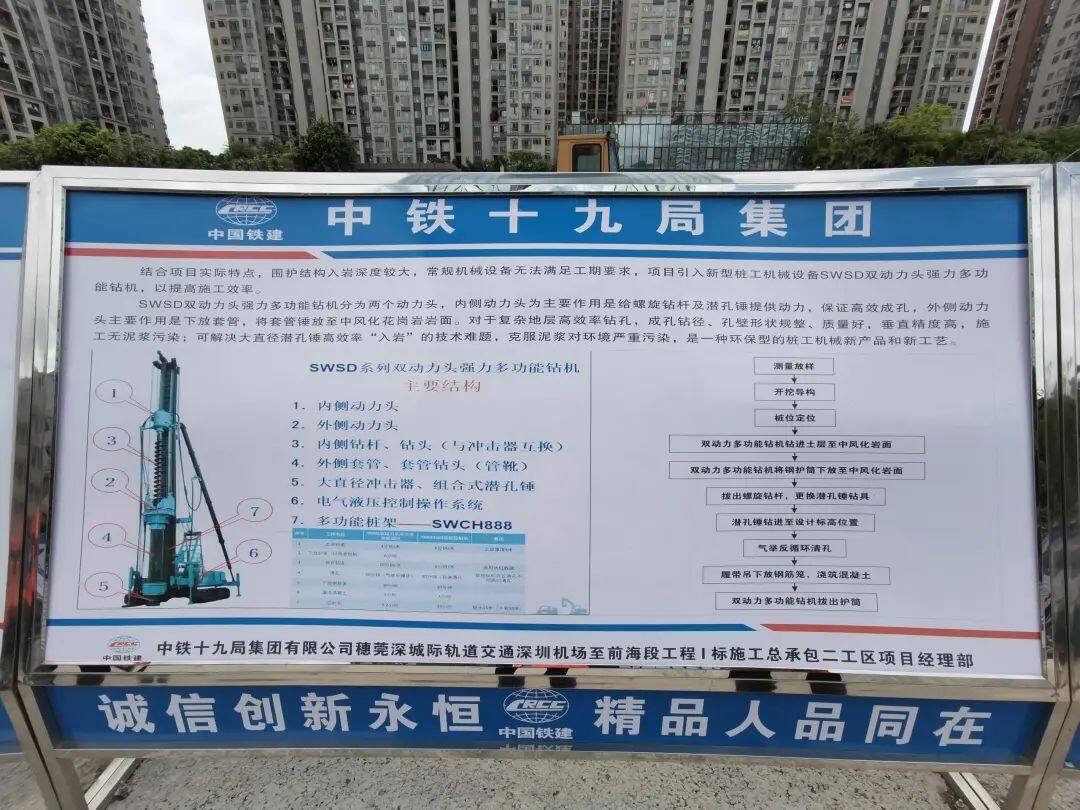

Through talks and exchanges, Sunward Intelligent customized a complete set of solutions for the customer according to the customer's needs, combined with the environmental characteristics and construction geological conditions of the construction project - the construction technology of reverse circulation DTH hammer, and suggested that the customer use Sunward Intelligent's new pile driver Machinery and equipment SWSD series double power head powerful multi-function drilling rig and rotary drilling rig cooperate with high efficiency in construction.

What are the advantages of such a scheme? "On the one hand, it can solve the technical problem of low construction efficiency of 'rock entry', and the slag can be discharged while drilling, which greatly saves construction time and improves construction efficiency; on the other hand, it also eliminates the serious pollution of mud and dust to the environment. And the new construction technology greatly reduces the noise compared with the traditional rotary excavation construction." Sunward Intelligent technicians explained.

"I only knew that it would take a lot of time to hit rock formations with a rotary drilling rig, and the performance and stability of the machine are extremely demanding, and the construction cost cannot be estimated at all. After that, it is almost several times faster than the traditional rotary drilling rig's rock entry speed." The on-site construction staff said with satisfaction: "According to the construction technology plan provided by Sunward Intelligent, and cooperated with the rotary drilling rig, it saves a lot of time. It takes 104 hours to form a hole with a rotary drilling rig, a pile with a pile diameter of 1.2 meters and a pile depth of 33 meters (22 meters into the rock), and the dual-power head drilling rig + rotary drilling rig construction, the same pile only needs to be formed into a hole. 17 hours."

In addition to the Guangzhou-Dongguan-Shenzhen Intercity Rail Project, Sunward Intelligent has also provided a variety of underground engineering equipment and complete sets of solutions for many major national engineering projects such as the Hangzhou-Shaoxing-Ningbo Smart Expressway and the Shenzhen-Zhongshan Corridor, showing that it is a leading enterprise in the comprehensive field of underground engineering. Strength.

Next, Sunward will continue to give full play to the advantages of "pioneering innovation", closely follow the needs of national development, develop more innovative equipment, and at the same time provide customers with more high-quality solutions and create greater value for customers.Editor/Xing Wentao

Comment

Praise

Praise

Collect

Collect

Comment

Comment

Search

Search

Write something~