- Since joining CRCC, Zhang Shuikun has devoted himself to the research and development of mud-water balance shield machine

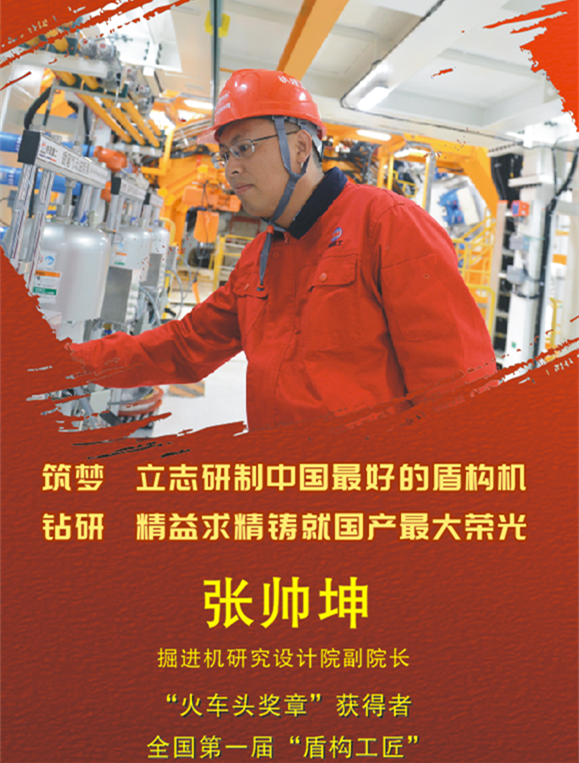

In CRCC, there are a group of outstanding model workers who are working hard in the front line of production and research and development, creating extraordinary achievements with ordinary labor, and interpreting the spirit of model workers and craftsmen with practical actions. Now, I will tell you about the Vice President of the Research and Design Institute of the Roadheader Research and Design Institute of the R&D and Operation System of the Railway Construction Heavy Industry, the "Lokomotiv Medal" of the All-China Railway Federation, the first Hunan Craftsman, the Changsha High-level Talent Green Card, and the first national "Shield Craftsman" "The story of winner Zhang Shuikun.

"The maximum excavation diameter is 16.07 meters. It is not only large, but also powerful." Talking about the "Jinghua", Zhang Shuikun, vice president of the Roadheader Research and Design Institute of CRCC, smiled. "This is the first time that a Chinese enterprise has successfully realized the industrial manufacturing of a 16-meter-level super-diameter shield machine. The development and application of the equipment has effectively consolidated the independent and controllable capability of the core technology of the domestic super-large-diameter shield machine."

At CRCC, the "big guy" that Zhang Shuikun participated in the development of is not only the "Jinghua". "Yuan'an", "Zhenxing", "Xingsheng"... Since joining CRCC in 2010, Zhang Shuikun has only devoted himself to one thing for 12 years - research and development of mud-water balance shield machine.

Chasing dreams and moving forward

In 2008, Zhang Shuikun entered the shield machine industry after graduating from university, mainly engaged in the use and supervision of equipment. At that time, all the shield machines used in domestic construction were imported. During his work, Zhang Shuikun gradually discovered that imported equipment is not only expensive, has a long production cycle, and has untimely accessories and services, but also has the phenomenon of "acclimatization".

"In China, the geology of different regions is very different, and each shield machine needs to be customized. However, the R&D personnel of foreign shield machine manufacturers rarely come to the domestic construction site for on-the-spot inspection, but only learn from the experience of similar formations in the past. , once the geological incompatibility occurs, it will bring huge safety risks and unpredictable economic losses." In view of this situation, Zhang Shuikun is determined to develop China's own shield machine.

Because of his love for design and in order to realize his dream of developing a domestic shield machine, in 2010, Zhang Shuikun joined Tiejian Heavy Industry, started from scratch with the team, worked hard, independently developed a mud-water balance shield machine, and started his pursuit. Dream trip.

Zhang Shuikun rarely has time to accompany his parents, wife and daughter. He is either working overtime or traveling on business. He uses persistence, hard work and sweat to complete one R&D project after another.

In 2013, Zhang Shuikun led the team to successfully develop the first domestically produced 6-meter-level composite mud-water balance shield machine, realizing the first domestic shield machine to cross the Hunhe River.

In 2014, Lanzhou Metro Line 1 started construction across the Yellow River section, and the crossing stratum is a water-rich full-section pebble stratum. Zhang Shuikun led the team to break through a number of core technologies, and achieved the first domestic shield machine to cross the Yellow River.

In 2016, the first domestically produced large-diameter mud-water balance shield machine for high-speed rail "Wangjing" and the first domestically produced double-track super-large diameter mud-water balance shield machine "Zhongyuan No. 1" rolled off the production line at the same time, ending the production of large-diameter mud-water balance shield machines. The situation in which "foreign shield machine" dominates the world in the field of machine construction.

In the early morning of February 14, 2018, two days before the Lunar New Year's Eve, when the 14th tool was replaced at the construction site of Yuanjiang Tunnel in Changde, Hunan, the gate was closed, the tool was about to be pulled out, and suddenly there was a mud gushing phenomenon, nearly 30 meters away. The mud at the head pressure is sprayed into the cutter head cavity. The knife-changing work was stopped. In order to ensure the absolute safety of the personnel, Zhang Shuikun did not care that his daughter was just born. When he received a call at 1 a.m., he immediately rushed from Changsha to Changde with his team members to find out the problem...

It is with this dedicated work attitude that in September 2017, the first domestically produced atmospheric-pressure tool-changing large-diameter mud-water balance shield machine "Yuan'an" with complete independent intellectual property rights was successfully accepted and rolled off the assembly line in Changsha. The birth of the equipment fills the blank in the field of atmospheric pressure tool change technology for domestic shield machines. Before that, the atmospheric pressure knife-changing mud-water balance shield machine was monopolized by foreign countries. Zhang Shuikun led the team to break the monopoly of foreign technology and win dignity for Chinese manufacturing.

Glory of the Forge

Before the advent of the "Jinghua", the domestic shield machine with a conventional diameter of 6-8 meters and a large diameter of 8-15 meters achieved rapid development, realizing the leap from the substitution of imported equipment to the realization of export of domestic equipment.

Zhang Shuikun said frankly that compared with conventional diameter and large-diameter shield machines, the system integration of super-large diameter shield machines above 15 meters is more complicated, the processing and manufacturing are more difficult, the reliability requirements are higher, and the engineering application risks are greater. The weak areas of shield machine technology research and development, promotion and application.

Starting from February 2020, Zhang Shuikun led the team to work together to overcome difficulties and face difficulties. At that time, the new crown pneumonia epidemic broke out, but the R&D design could not be delayed for a day. It was almost impossible to communicate with customers face-to-face. The R&D team could only discuss and confirm the parameters of the shield machine with customers through video conferences. Generally, the production cycle of a large-diameter shield machine is more than 12 months, but under the background of normalization of epidemic prevention and control, the R&D team accelerated the design and demonstration speed, and the production workshop worked overtime. Only 7 "Jinghua" were used. moon. "

The research and development cycle is shortened, and the technical gold content and quality of "Jinghua" are not compromised at all, and it has become the master of the technology of the super-large diameter shield machine developed by CRCC. Zhang Shuikun proudly said that "Jinghua" is the largest diameter shield machine made in China in terms of scale, and it is also at the world's leading level in terms of technical application.

Concentrating on research to light up the highlight moment, "Jinghua" was selected into the book "Xi Jinping Thought on Socialism with Chinese Characteristics for a New Era", and appeared at the National "Thirteenth Five-Year Plan" Scientific and Technological Innovation Achievement Exhibition. The "net red" heavy tool. All these have inspired Zhang Shuikun and his R&D team.

struggle endlessly

During his 12 years at CRCC, as the design director, Zhang Shuikun successively participated in major projects such as Hunan Province's major science and technology project "Development and Application of Super-large Diameter Tunneling Equipment" and the National 863 Program "Research and Application of Key Technologies for Super-large Diameter Slurry Shield". . Up to now, more than 20 sets of large-diameter shield machines with a diameter of more than 10 meters have been developed and 11 sets of more than 14 meters have been exported to South Korea, India and other countries.

While concentrating on technology and product research and development, Zhang Shuikun, along with the rapid development of the company, has always maintained a pure heart of constantly surpassing himself and daring to pursue dreams, building a national weapon, and making domestic shield machines more and more powerful. Just because here, "digging" wins at the right time!

Greatness comes from the ordinary, and the ordinary creates greatness. Let us follow the advanced model workers, always strengthen our confidence, keep our energy, promote the spirit of labor, overcome difficulties and obstacles, continue to write extraordinary stories in ordinary positions, and use our hard work to contribute more to the development of the enterprise and the Chinese dream. Contribute to the beauty of your labor! Editor/He Yuting

Comment

Praise

Praise

Collect

Collect

Comment

Comment

Search

Search

Write something~