- Shanghai Jintai trench cutter has low fuel consumption and fast efficiency, making it an expert in energy efficiency

The fuel consumption is only half of similar products, and the efficiency is the fastest. Whose product is this? This is the product of Shanghai Jintai, the SX50 high torque gas lift reverse circulation trench cutter. A few days ago, this product has performed prominently in the project of Bao'an Station, the second standard of the Shenzhen Airport to Qianhai Section of the Guangzhou-Dongguan-Shenzhen Intercity Rail Transit, with obvious advantages. In terms of fuel consumption, rock entry efficiency, construction accuracy and other multi-dimensional dimensionality reduction, it has attacked similar competing products on the scene, and has won unanimous praise from local customers. It is a well-deserved light of domestic products.

It is understood that the first section of the Guangzhou-Dongguan-Shenzhen intercity starts from the Shenzhen Airport Station of the Guangzhou-Shenzhen Intercity and ends at the Qianhai Station. It is an important part of the Guangzhou-Shenzhen main axis of the intercity railway network in the Greater Bay Area. The line passes through Hangcheng, Xixiang and Xin'an Streets in Bao'an District to the Qianhai Comprehensive Transportation Hub, with a total length of about 15.2 kilometers. The entire line is laid underground with a total of 3 stations: Xixiang, Bao'an and Qianhai. The project has a design speed of 160 km/h and uses 8-car CRH6 EMUs. It is planned to be completed and opened in 2025.

The Bao'an Station under construction of SX50 is located on Bao'an Avenue, between Yu'an 1st Road and Chuangye 1st Road. The scale of the station is 314m (length) × 25.1m (width), the excavation depth of the foundation pit is 30.5-32.87m, the underground three-story, two-column, three-span island-type station is constructed by open-cut construction, with 4 entrances and exits attached, and 2 groups of Wind Pavilion. The surrounding buildings are densely distributed, and there are various types of underground pipes and lines such as underground communication pipelines, cables, gas pipelines, water supply and drainage pipes, etc. on both sides of the main road along the line.

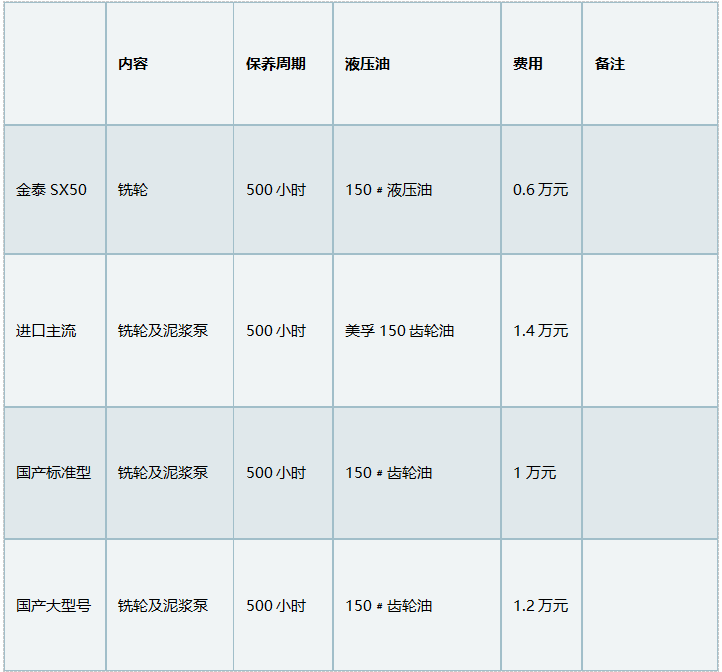

The project has a total of 120 groove sections, including 107 standard sections, 7 "z"-shaped groove sections, and 6 "L"-shaped groove sections. The thickness of the underground diaphragm wall in the middle part of the main enclosure structure of Bao'an Station is 1000mm, the thickness of the underground diaphragm wall at the end is 1200mm, and the depth of the diaphragm wall varies from 34.7 to 37.7m. The stratigraphic structure from top to bottom is plain fill, silty clay, sandy clay, fully weathered granite, fragmented strongly weathered granite, and moderately weathered granite. The ground wall construction equipment mainly adopts Jintai SG70 grab bucket, SX50 trench cutter, a certain domestic large-scale, standard type trench cutter and imported mainstream trench cutter for groove construction, and the rotary drilling rig cooperates with the construction.

This project adopts the combined construction technology of grasping and milling. Jintai SG70 hydraulic diaphragm wall grab bucket is used for construction in the stratum above the fully weathered. The rock section is milled with a trench cutter, and there are multiple trench cutters in the same section for construction at the project site. Jintai SX50trench cutter, an imported mainstream trench cutter, a domestic large-scale trench cutter and a standard trench cutter.

Local granite samples

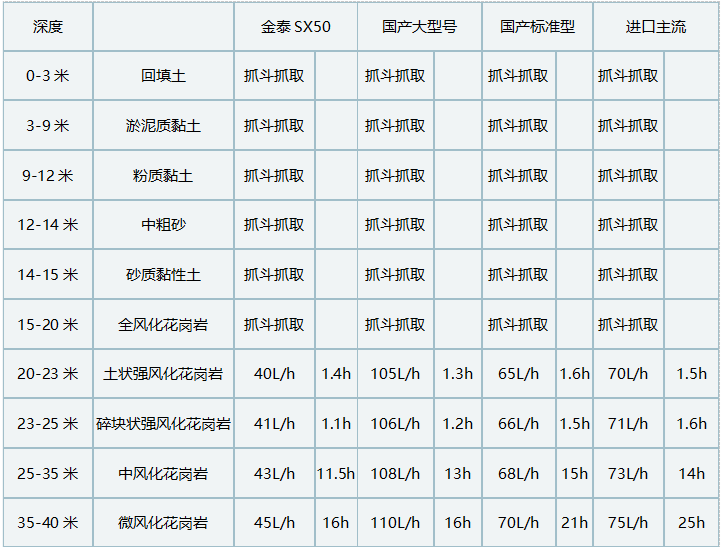

The construction efficiency of Jintai SX50trench cutter is more than 30% faster than that of imported mainstream trench cutters and domestic standard trench cutters; it is about 5% faster than that of domestic large-scale trench cutters.

fuel consumption ratio

Oil consumption ratio after rock entry

Jintai SX50trench cutter saves more than 30% oil cost than similar products on average when the "oil price" is relatively stable. If the oil price is higher, the difference will be larger, and the environmental protection advantage is obvious.

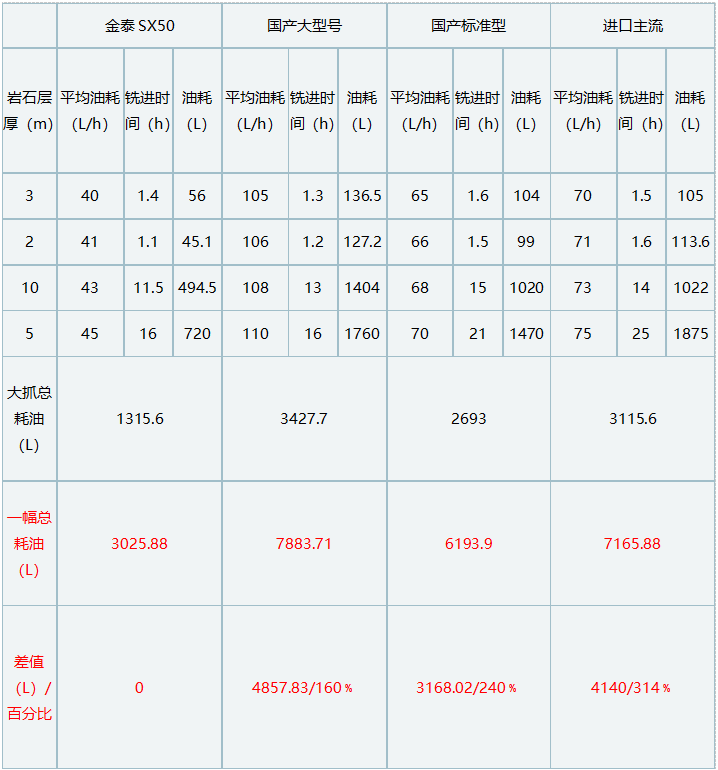

Equipment maintenance cost

Due to the huge difference between Jintai SX50 gas lift reverse circulation trench cutter and pump suction trench cutter, there is a huge difference in maintenance costs. In addition to the maintenance of the same milling wheel as the SX50 gas lift trench cutter, the pumping trench cutter also has extra maintenance costs for the mud pump and the slag discharge hose. Among them, the maintenance cost of the light slag discharge hose is more than 900,000 yuan more than that of the SX50trench cutter every two years. On the other hand, the maintenance cost of Jintai SX50trench cutter is almost "zero" except for the maintenance of the milling wheel.

The daily maintenance of various manufacturers and models is basically the same, mainly the oil pollution and temperature rise of the milling wheel box, as well as the wear of the cutter head and cutter head. The maintenance cycle is generally about one week; the cost is generally about 1,000 yuan.

small maintenance

It can be seen that the later maintenance cost of Jintai SX50 gas lift reverse circulation trench cutter is more economical and practical than that of the above three pump-suction trench cutters, which greatly saves not only equipment maintenance costs, but also a lot of labor costs.

It's obvious who the "energy efficiency experts" are! Shanghai Jintai is the first of its kind in China. It has been 11 years since 2011. It has been developing trench cutters for 11 years. It has participated in hundreds of provincial and municipal key projects, and has milled more than 200 MPa hard rock. It has entered the deepest groove of 140m+ in China. Passing through the highest no-man's land in China at an altitude of 3200 meters, and resisting the coldest outdoor temperature of -20℃ A well-deserved "energy efficiency expert". Editor/He Yuting

Comment

Praise

Praise

Collect

Collect

Comment

Comment

Search

Search

Write something~