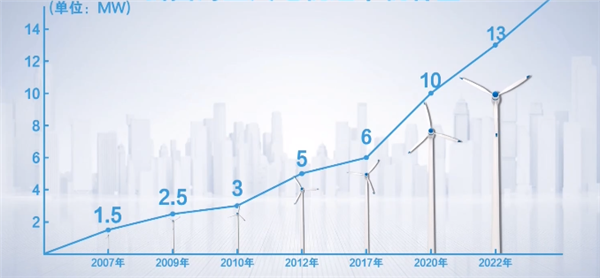

- From 2007 to 2022, the single unit capacity of China's offshore wind turbines jumped from 1.5 MW to more than 15 MW

- At the beginning of 2022, China's 13MW typhoon-resistant offshore wind turbines went offline, marking China's offshore wind power technology at the forefront of the world

Over the years, China has started from a 1.5MW wind turbine in 2007, to a 3MW wind turbine in the Donghai Bridge in 2009, to a batch of single-machine 4MW units in the Three Gorges Xiangshui Offshore Wind Farm, to a 13MW large wind turbine incubated in the Fujian Three Gorges Offshore Wind Power Industrial Park, all the way. Come, China and European and American countries, from the very beginning, to slowly running together, we believe that in the near future, we will be able to produce wind turbines of more than 15MW. We must realize the dream of all offshore wind power people, and we must lead . ——Lv Pengyuan, Deputy General Manager and Party Committee Member of China Three Gorges New Energy Group.

To compete with the sea, to compete with the sea

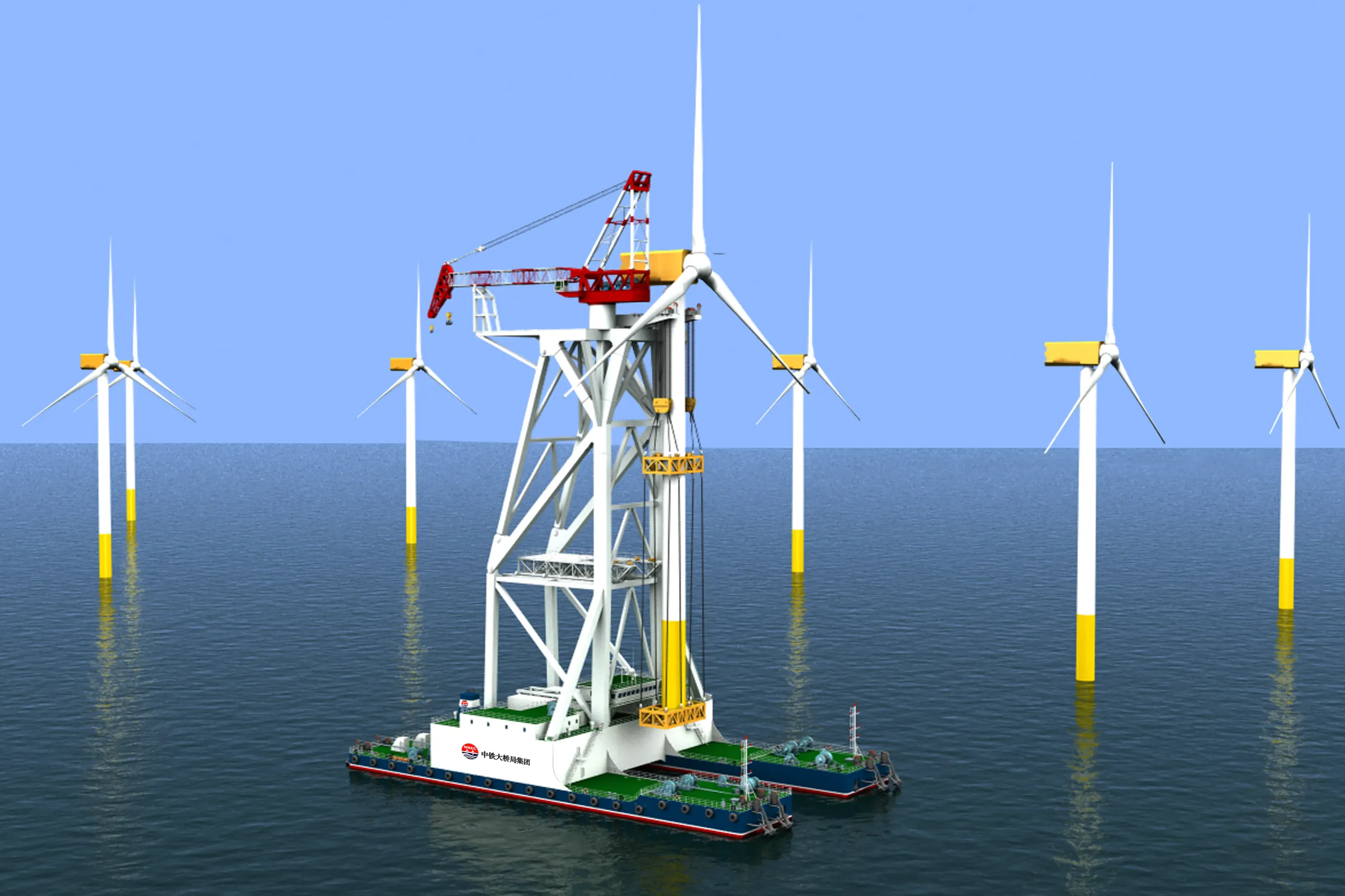

The impact of ocean currents, the corrosion of sea water, the raging of typhoons, long-distance transportation, etc. These are all problems that offshore wind power personnel need to overcome.

Lv Pengyuan said that the biggest difficulty of offshore wind power is to compete with the sea. We offshore wind power people are the ones who catch the sea. We need to have the spirit of riding the long wind and breaking the waves of thousands of miles to contribute to China's offshore wind power industry and to achieve "carbon neutrality and carbon emission". The "peak" goal is to cut through all obstacles.

At the beginning of 2022, the 13MW typhoon-resistant offshore wind turbine independently developed by my country with completely independent intellectual property rights was successfully rolled off in Fujian Three Gorges Offshore Wind Power International Industrial Park. The unit can withstand super typhoons above level 17 and is suitable for 98% of my country's sea areas.

The 13MW offshore wind turbine off-line is another important milestone for my country's large-scale models, and it also marks that our offshore wind power technology is at the forefront of the world.

According to Lu Pengyuan, the height of this fan from the foundation to the hub is 130 meters, which is equivalent to a 40-story building. The diameter of the impeller is equivalent to the width of three Fujian aircraft carriers side by side. The power generation capacity is about 50 million kilowatt-hours, which can provide electricity for 25,000 families of three in China for a year. Compared with thermal power, its full production can save us 15,000 tons of coal a year and reduce carbon dioxide emissions by 38,000 tons.

From 2007 to 2022, in 15 years, the single-unit capacity of China's offshore wind turbines jumped from 1.5 MW to more than 15MW in the second half of the year, and the single-unit capacity of our wind turbines has doubled in 15 years. It is increasing at a rate of one megawatt per year.

Lu Pengyuan said that this is easy to say, but it is actually very difficult to do. Sometimes the capacity may increase a little bit, but the difficulty in design and manufacturing is an order of magnitude increase. These are all designers, builders, manufacturers, etc. All wind power people work together and work together, sometimes without sleep, to achieve such a result.

Break the monopoly and compete with foreign countries

In order to promote the innovation of large-scale offshore wind turbines in my country, Three Gorges has built a large-scale test wind farm in Xinghua Bay, Fujian, with a total of 14 wind turbines, covering almost all mainstream offshore wind turbine manufacturers at home and abroad. Compete against each other and compare with each other to promote the technological development and innovation of my country's domestic large offshore wind power models.

Up to now, we should be able to say responsibly that our domestic wind turbines of the same type, our availability, and our power generation efficiency are no worse than foreign wind turbines, and even some of our manufacturers are better than it. Lu Pengyuan said so.

Lu Peng said in a general sense that from nothing, from small to large, from weak to strong, he would be extremely proud to have come this way. Many people say that the significance of localization of wind turbines is to reduce costs. I think this is only one aspect. Localization determines how large the scale of my country's offshore industry development can be and how far the development of offshore wind power can go. If we still have some core technologies in the hands of foreigners, the road of offshore wind power will not go fast, not far, and not stable.

Take the offshore wind power piling hammer as an example. In the past, a piling hammer imported nearly 100 million yuan, and the cost was very high. At present, the construction effect of domestic piling hammer equipment is not inferior to that of foreign countries, but the price is much lower than that of imports.

During the development of the 13MW offshore wind turbine, the problem of "stuck neck" was also encountered. Zhao Wei, deputy director of Dongfang Electric Wind Power R&D Center, recalled that in the past, large-scale wind turbines in the world used hydraulic pitch systems, but this system was The two Danish manufacturers are monopolized. In the process of communicating with them, not to mention the high price, the other party is also very arrogant and strong. They feel that China's large megawatt offshore wind turbines must use their products, and they must use their products. Full set.

Driven by this unconvincing and unyielding spirit, through unremitting efforts, constant pondering and research and various aspects of research, after hundreds of rounds of experiments, the dual-drive electric pitch was finally replaced. The cost of hydraulic pitch is only one third of that of foreign hydraulic pitch systems, and the operation effect is very good.

Zhao Wei said that since then, many manufacturers that used hydraulic pitch control in the past have turned to our electric dual-drive pitch control. At the same time, we also took the lead in formulating national standards, realizing the localization of key core technologies, and making key technologies firmly in our own hands. In the hands, do not act on the face of others.

In terms of blades, the blade length of the 13 MW offshore wind turbine reaches 103 meters. Glass fiber can no longer be required in terms of weight and toughness. Carbon fiber main beams must be used. This is the first time to use without any experience and precedent. In the end, Through repeated process experiments, continuous rework and experience summarization, the blade was successfully born and became the longest wind power blade in China at that time.

It is worth mentioning that during the entire development process of the 13 MW offshore wind turbine, Dongfang Wind Power has carried out more than 10 technological innovations, overcame more than 20 key technologies, and realized the localization of almost all key components.

Dare to explore and move forward to the far-reaching sea

In Lv Pengyuan's view, the future of offshore wind power will not only achieve large-scale wind turbines, but also advance to the far-reaching sea, achieve technological breakthroughs in floating offshore wind power, and realize large-scale development of offshore wind farms.

China's "14th Five-Year" renewable energy plan points out that it is necessary to carry out deep-sea offshore wind power planning, promote large-scale offshore development and deep-sea demonstration development, and strive for resources and resources such as Guangdong, Guangxi, Fujian, Shandong, Jiangsu, Zhejiang, Shanghai, etc. In areas with good construction conditions, combined with the construction of base projects, we will promote the construction of a batch of 1 million kilowatt-class deep-sea offshore wind power demonstration projects.

However, the construction of offshore wind power is inherently technically difficult. From the offshore to the deep sea, the difficulty factor has increased exponentially. How can we promote the wind farm to the deep sea through technological innovation?

The first is the issue of power transmission. The distance from the offshore wind farm is getting farther and farther. How can the electricity be delivered with the least loss? Flexible DC can minimize losses, but the application of this technology at that time, whether domestic or international, had no precedent and experience in projects. Three Gorges dared to explore and dared to be the first person to eat crabs. In the end, China's first plus or minus 400kV flexible DC submarine cable transmission offshore wind farm was built. The Three Gorges Rudong offshore wind farm set several records at that time, with the longest transmission distance in China, up to 108 kilometers; the voltage level is the largest in China, Plus or minus 400 kV; the largest offshore converter station in the world, weighing 22,000 tons.

At present, the operation of the Three Gorges Rudong offshore wind farm is surprisingly good, said Lv Pengyuan.

In terms of foundation, the traditional offshore wind power foundation construction is to directly insert the base into the seabed. As the construction water becomes deeper and deeper, the traditional construction method is very expensive, and the requirements for construction ships are also very high. Offshore wind turbines have become one of the essential key technologies for the deep sea.

At the end of 2021, my country's first floating offshore wind power platform "Three Gorges Leading" Guangdong Yangjiang Offshore Wind Farm was successfully connected to the grid for power generation, marking my country's first independent research and development, manufacturing, installation and Operational capability.

It is understood that the "Three Gorges Leading" has a single unit capacity of 5.5 megawatts and can deliver 40 million kWh of clean electricity every year, which can meet the normal electricity consumption of 11,000 families of three for one year, and is expected to reduce carbon dioxide emissions by about 20,000 tons per year.

Lv Pengyuan introduced that the biggest difference between floating offshore wind power and traditional offshore wind power is the word "floating". It floats on the water surface, and the floating body and the seabed are connected and fixed by mooring systems. The wind turbine is like a tumbler. It is currently floating in the Yangjiang Offshore Wind Farm in Guangdong and is operating very well.

Continuous innovation to lower costs

The wind comes from the sea, and the electricity is generated from the wind. Because of its high operating efficiency, short power transmission distance, no land occupation, and suitable for large-scale development, etc., in the energy "14th Five-Year Plan" issued by many coastal provinces in my country, offshore wind power will be adopted. as an important development direction in the future.

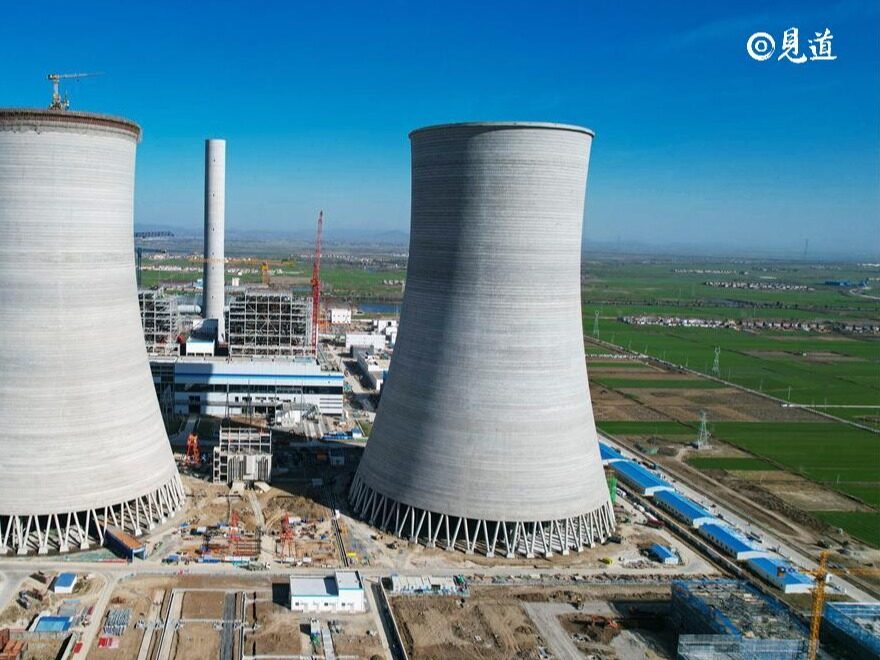

Starting from 2022, the national financial subsidies for offshore wind power will be fully withdrawn, and grid parity has become an inevitable trend for the future development of offshore wind power. Taking Guangdong as an example, the electricity price of offshore wind power was 0.85 yuan/kWh before, and after parity, it is 0.453 yuan/kWh, or even more. Low, how can my country's offshore wind power achieve self-reliance in the era of parity and find a way to make green energy more inclusive?

Lv Pengyuan pointed out that, first of all, it is necessary to develop offshore wind power on a large scale, which can effectively dilute the cost; Guangdong Yangjiang Phase 1, 2, 3, 4 and 5 is currently the first one million kilowatt-class wind farm in China, which can play a role in the development of offshore wind farms at an affordable price. Demonstration.

The second is to insist on large-scale wind turbines. Take a 1 million kilowatt offshore wind farm as an example. Compared with 10 MW, 13 MW can reduce 23 units, which means 23 less foundations, including submarine cables, Transmission lines, etc., the same capacity can reduce investment by about 500 million yuan;

The third is to continue to promote the localization of equipment. With the continuous upgrading and iteration of localized equipment technology, the cost of use is also decreasing.

The fourth is to improve the management level of project participants such as construction units and development units; the last is to reduce some non-technical costs.

Qin Haiyan, secretary general of the Wind Energy Professional Committee of the China Renewable Energy Society, said that by the end of the "14th Five-Year Plan", the cost of wind power can be further reduced by "12345". That is to say, in places with good onshore wind resources, electricity is 10 cents, onshore is 2 cents in places with moderate wind resources, 3 cents in places with poor wind resources, 4 cents in all offshore areas, and then 100 kilometers away from the sea. In addition to 5 cents, this is the goal that we predict can be achieved during the "14th Five-Year Plan".

Qin Haiyan pointed out that by 2025, the cumulative installed capacity of China's offshore wind power will reach 60 million kilowatts, almost doubling, and by 2030, the cumulative installed capacity of each province and the development speed of industrial technology will reach 60 million kilowatts. The installed capacity can reach 120 million, doubling again.

In order to promote the innovation and development of my country's offshore wind power and promote the cooperation and exchanges of enterprises in the industrial chain, Polaris Power Network and Polaris Wind Power Network will hold the "New Era, New Opportunities and New Journeys - The Second Offshore Wind Power Network" in Nanjing, Jiangsu Province on August 11-12, 2022. "Innovation and Development Conference", the conference will invite functional government departments, owner units, corporate leaders, universities, design institutes, complete machine units, construction and transportation companies, operation and maintenance companies and other industrial chain participants to gather together to discuss policies, markets, In-depth discussions will be held on topics such as cutting-edge technology, floating wind power demonstration, engineering construction optimization, industrial diversified development, and innovation in operation and maintenance management, and discuss the new journey of offshore wind power during the "14th Five-Year Plan"! Editor/Zhao E

Comment

Praise

Praise

Collect

Collect

Comment

Comment

Search

Search

Write something~