- The development of Weichai Power helped China's power system quickly shorten the gap with the world's leading technology

On October 24, 2022, the world-famous Bauma Exhibition in Germany kicked off at the Munich Exhibition Center. As the compass leading the development direction of the world's construction machinery industry, this mechatronics feast once again attracted extensive attention from the global construction machinery manufacturing industry.

In recent years, looking at the development of the construction machinery industry, there has been a big reversal between domestic brands and foreign brands. The situation of foreign brands dominating the world in the past is gone forever. Both in traditional fields such as machining, internal combustion engine, transmission system and hydraulic components, and in new fields such as intelligent driving and new energy power, we have gained unprecedented new advantages. As a leader in the internal combustion engine industry, Weichai has gone from chasing to leading, helping China's construction machinery industry to a higher level, and bringing a new "Chinese standard" for industry development and participation in international competition.

In the field of power, Weichai took the lead in releasing the world's first diesel engine with a thermal efficiency of 51.09%, achieving a breakthrough victory in the history of the development of internal combustion engines in the world, and occupying the technical commanding heights in the field of global power. While mastering the key core technologies in the field of traditional power assembly, we have also successfully built a new energy power system integration advantage of "battery+motor+electronic control", moving towards the three development trends of economy, cleanliness and high horsepower at full speed.

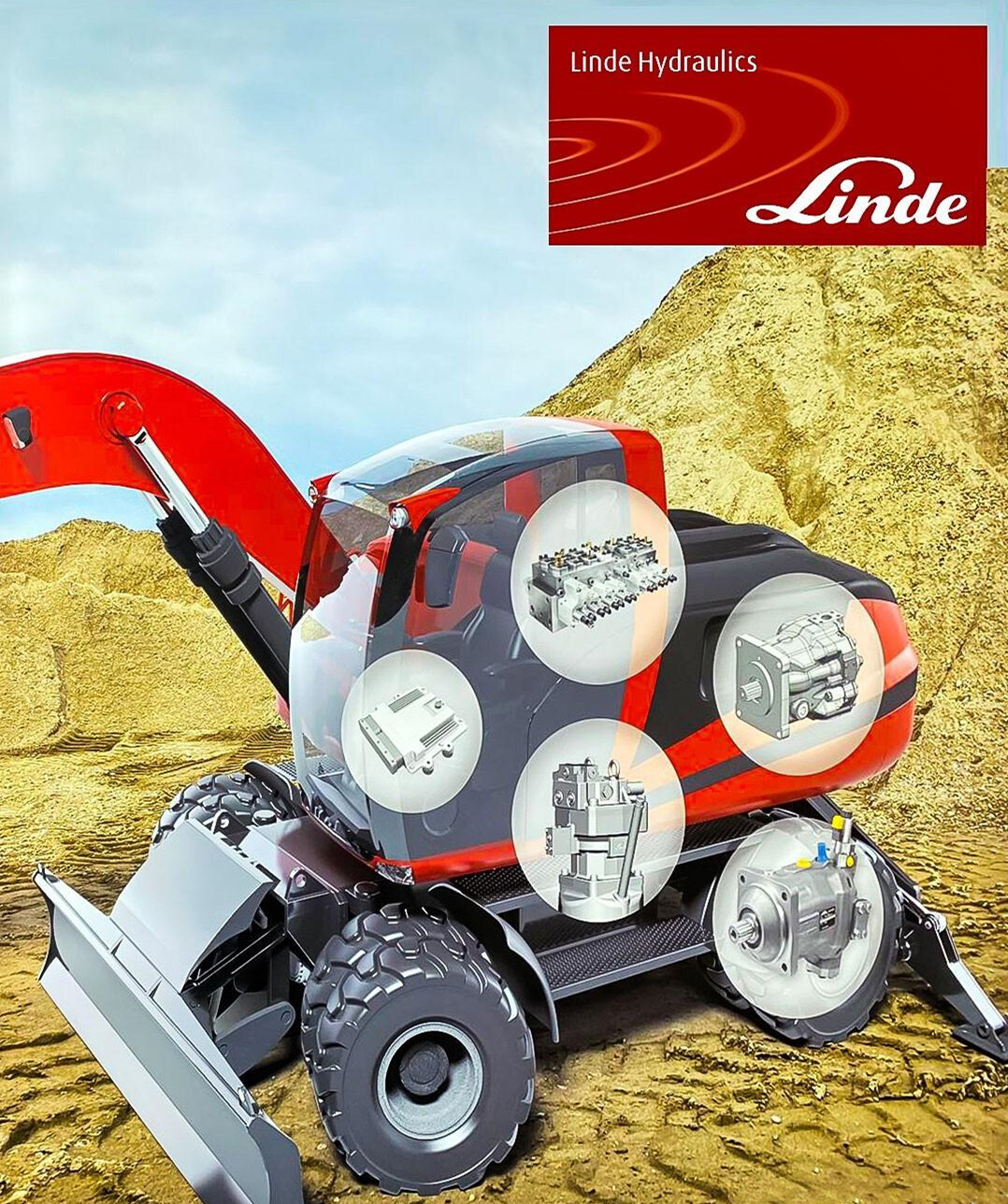

In the industry, there has always been a saying that "those who get hydraulic pressure win the world". Hydraulic pressure is almost related to the competitiveness of a country's equipment manufacturing. Weichai Power's forward-looking action of strategic restructuring of Linde Hydraulic more than a decade ago has completely changed the situation that China's high-end hydraulic core technology has been monopolized by foreign countries for a long time, and promoted China's equipment manufacturing industry to expand to the high-end of the value chain.

After Linde Hydraulics landed in China, Weichai successfully built the world's first hydraulic power assembly by combining the advantages of complete machine resources, engine, gearbox, electronic control system and other core parts resources, providing an integrated solution for the subdividing field of engineering machinery, covering nearly 20 subdividing scenes of engineering machinery, special vehicles, agricultural machinery, etc.

Weichai Engine and Linde Hydraulic have created a differentiated advantage to deal with different working conditions through chain innovation, collaborative development and control and other means, which has already dominated multiple subdivisions, such as loaders, cranes, concrete mixers, wide body dump trucks, bulldozers, graders, road rollers, and so on. Their market share in the engineering machinery market segment has ranked first and is far ahead.

Taking the excavator hydraulic power assembly as an example, Weichai engine, Linde hydraulic, and the whole machine were developed, matched, and tested cooperatively. For the first time in the industry, the engine and hydraulic strategies were matched cooperatively, with lower fuel consumption. In 2021, the sales exceeded 20000 sets. The comprehensive fuel consumption of hydraulic power assembly products of 20t-70t full line excavator is more than 15% lower than that of competitors; The dynamic performance of 5000m plateau is 10% better than that of competitors. The continuous optimization scheme of non road national four products, the continuous optimization of engine, hydraulic pump, fully electrically controlled valve, whole machine matching, etc. further reduced the fuel consumption.

Another example is the static pressure power assembly of the loader. Weichai engine covers the 3-11T hydraulic power demand, creating a cost-effective and differentiated advantage. WP4.6N is equipped with 30 loaders, which have strong power, low fuel consumption, low noise, and good emission adaptability. The terminal market is running 2000 sets, and the longest running time is 5846h. The fuel consumption of the whole vehicle is reduced by more than 5.5% compared with the competitors. The WP10H is equipped with 50 loaders in four non road stages. The single action responsiveness and fuel consumption efficiency of all models are better than those in three stages of WP10. The terminal is running 3000 complete machines, and the power, economy and reliability are better than those of WP10, achieving perfect upgrading.

In the crane field, the engine and electrically controlled variable displacement pump are jointly controlled, which is the first time in the industry to realize the non interference between lifting operation and regeneration. The regeneration period under hoisting condition is extended by 2 times, the fluctuation of transient loading speed is reduced, the comprehensive oil consumption of hoisting and regeneration is reduced, and the comprehensive operation time is reduced.

The development of Weichai Power has, to some extent, broken our long-standing pattern of "strong host, weak components", led our power system to solve the "choke" problem, and helped our power system quickly shorten the gap with the world's leading technology. Weichai Linde Hydraulic Co., Ltd. appeared in bauma 2022, Germany, with a number of competitive products, demonstrating its hard core strength in the field of engineering machinery supporting. A3 Hall 149, welcome to Weichai Power Booth. Editor/Sang Xiaomei

Comment

Praise

Praise

Collect

Collect

Comment

Comment

Search

Search

Write something~