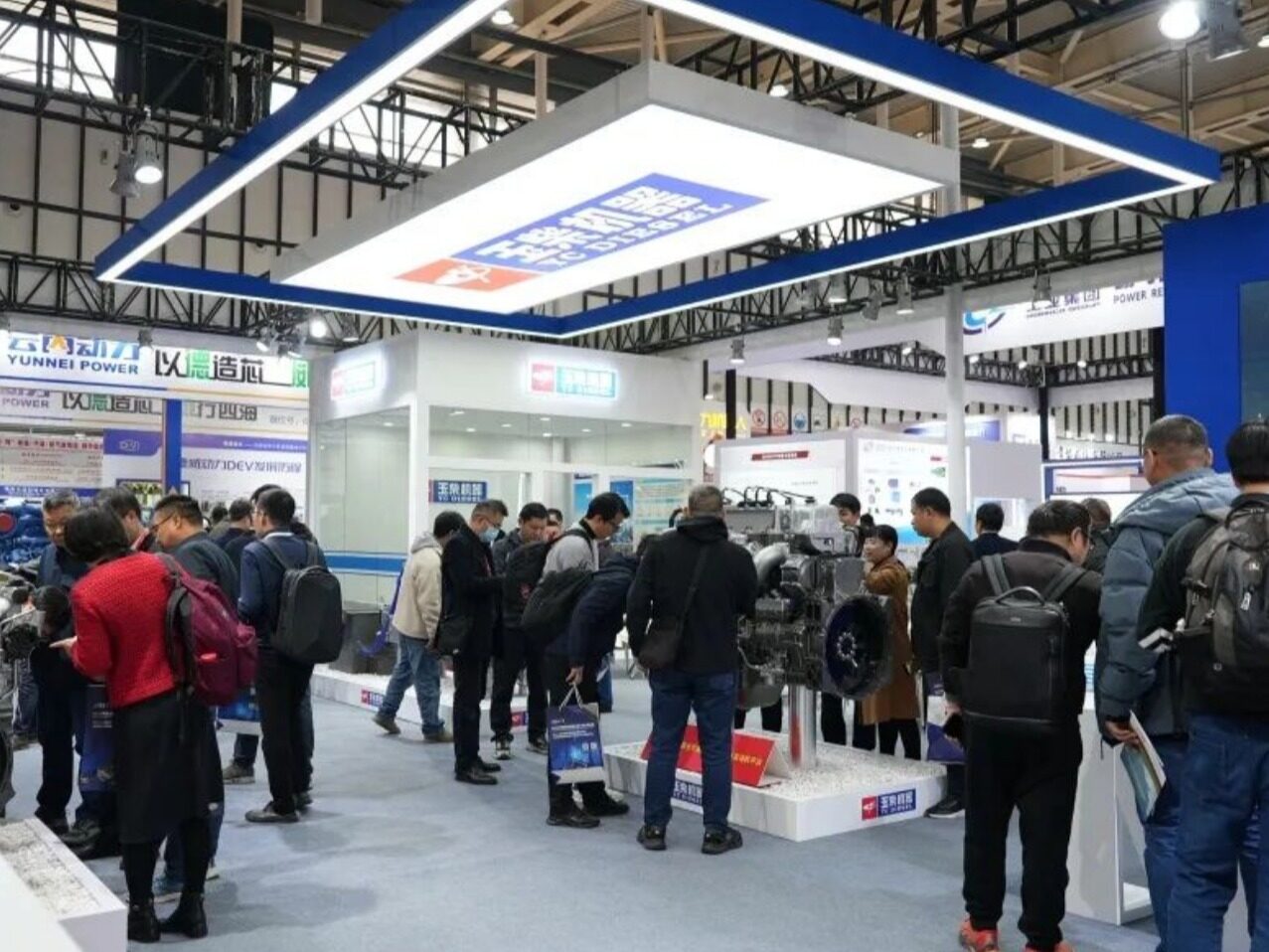

- As the creator of control technology of construction machinery, Tianbao undoubtedly firmly holds the right to speak technology

1978 is destined to be an extraordinary year. This year, Vandenberg Air Force Base successfully launched the world's first GPS satellite. In the same year, inspired by the American Dream, Charlie Trimble, who was unwilling to be mediocre, and his partners founded Trimble in the ancient Los Altos Theater in Silicon Valley. At the beginning of its establishment, Tianbao developed navigation and positioning products based on ground technology rather than GPS. But when the first GPS satellite was successfully launched, Charlie was keenly aware that GPS, a space based positioning system, might determine the position of any point on the earth with extremely high accuracy, which also meant that the original surveying and mapping and navigation industry would usher in a great change.

From its inception to the present, after more than 40 years of development and more than 70 strategic acquisitions, Tianbao has gradually built three core technology development directions: positioning technology, communication technology and information technology. With this, Tianbao has successively entered into many fields such as surveying and mapping, automobile navigation, engineering construction, mechanical control, transportation and logistics, and communication foundation, including engineering machinery industry.

How to iterate

The construction machinery industry is a fast moving industry from decentralization to centralization. Bezos, founder of Amazon, believes that there are two paths for the development of enterprises. First, starting from their existing capabilities, based on the existing core competitiveness, think about what room for improvement in the future. The second is to start from the future needs of customers, based on how to best meet customer needs in the future, push back and think about what new core capabilities you need to build.

The default development mode of many enterprises is the first path. Although this is more logical and easier to succeed, its development space will be limited. Tianbao wants to take the second path. This means that we must enter a new field, dare to build key capabilities that we do not have from scratch, and quickly build them into core capabilities to win in the future. This is why as early as 20 years ago, Tianbao decided to enter the construction machinery industry, which is now known as the automatic control system of construction machinery.

Those who plough deeply, leap into the abyss, and finally become legends! In 2000, Tianbao acquired Spectrum Precision Instrument Company, which has enhanced the company's ability in mechanical control, mapping, high-precision computing and other fields. Then Tianbao launched a high-precision mechanical control system based on 3DTPS/GPS - Trimble earthworks. This system can be used not only for all kinds of bulldozers, graders, shoveling machines, but also for pavers, milling machines and other road machinery.

What is a mechanical control system

The 3D control system can be divided into 3D GPS control system and 3D TPS control system, which are respectively applicable to projects with different accuracy requirements. 3D GPS control system is mainly used for earthwork or mining engineering machinery, such as bulldozer, grader, excavator, etc; The 3D TPS control system is mainly used for highway pavement or airport construction machinery with higher accuracy requirements, such as pavers, milling machines, etc. With the 3D GPS control system, the engineering design data can be directly input into the airborne computer to automatically generate a 3D digital model. The airborne computer compares the current position and design data of the construction machinery blade in real time, and outputs the correction control signal to the mechanical equipment to control the mechanical blade. As a result, this new control method discards the traditional measurement, piling, setting out and other processes, and solves the problems of elevation control, flatness control, slope control and so on at one time. Through 3D GPS control technology, the traditional engineering construction has entered a new era of digital construction.

Different mechanical equipment applications

In earthwork operation, one of the revolutionary changes is the 3D system proposed by Tianbao and Spectra Precision in 1995, which is also the beginning of the application of GPS technology in the field of engineering and construction machinery.

Trimble Earthworks excavator control platform controls excavation, leveling and shaping operations. The system uses an angle sensor, a biaxial sensor and a laser catcher to measure the relationship between the fuselage, cantilever, joystick and bucket to tell the driver the desired slope and depth, so as to shape at one time. The Trimble Earthworks bulldozer control system only needs to install dual GNSS receivers on the top of the cab, which greatly simplifies the installation and use of the system. The dual GNSS receiver is suitable for steep slope operation and complex design with high accuracy requirements. Trimble Earthworks grader slope control system can help operators with different operation levels to create high-quality surfaces. The combined configuration of Earthworks slope control system and Tianbao general total station can be used for fine grading, and high-quality flat ground surface can be obtained by reducing the number of leveling passes.

Trimble3D paving automatic control system can control the elevation error at millimeter level through high-precision intelligent total station to stereo control the plane position and elevation accuracy of paving operation, combined with automatic control, 3D digital modeling and wireless communication technology. In 2020, Tianbao released the Trimble Roadworks 2D paving control platform for asphalt pavers, which can automatically control the screed and improve the accuracy and efficiency of asphalt paving operations. As Kevin Garcia, general manager of professional solutions for Tianbao construction, said, "Trimble Roadworks has improved the paving control to a new level."

Strategic evolution from edge to future center

Beijing Daxing International Airport, located between Yufa Town, Lixian Town, Daxing District, Beijing, China and Guangyang District, Langfang, Hebei, is a 4F international airport and a world-class aviation hub, which was officially started in 2014. Before the construction of this super project, earthwork preparation is required. In order to ensure the accuracy and optimal efficiency of the airport project, the new airport construction headquarters needs all companies and contractors to adopt digital control construction methods to record and track the quality, progress and efficiency. Finally, Tianbao was chosen because only the solutions provided by Tianbao can meet every requirement of the bidding documents of the headquarters.

Since participating in the project, Tianbao has provided digital intelligent construction solutions for the original ground dynamic compaction, soil foundation and water stabilized layer compaction, concrete measurement and monitoring, etc. in 14 bid sections, realizing the integration of construction design modeling, construction quality monitoring and mechanical guidance in the airfield, and achieving the effect of "measurement upon construction". The previous quality inspection method of "point to area" has been changed, and the entire digital construction management system has won the first prize of 2018 Civil Aviation Science and Technology Progress Award.

Li Qiang, chief engineer of Beijing Daxing Airport, said: "The Tianbao digital construction solution helps the owner to clearly and quickly understand the on-site construction situation, which is the first time in China's airport construction project." In addition to participating in the construction of Beijing Daxing Airport, Tianbao also brought its "Jiuyang Zhenjing" in the field of digital construction to the construction of the the Belt and Road. The reconstruction and expansion project of Maldives Verana International Airport is an important project of the the Belt and Road jointly witnessed by the top leaders of China and Malaysia, and is constructed by Beijing Urban Construction Group EPC.

In order to meet the application objectives of the design, procurement and construction stages, and create a digital project management system driven by BIM model, the construction company has built the general layout model of Verana Airport Island and BIM model for digital construction of airfield. Among them, the BIM model of digital construction in the airfield is built using Sketch up/Triangle BC-HCE, which is one of the data cores of digital construction in the airfield. At the same time, Tianbao also provides various service contents, including site collaborative interconnection system, Trimble Connect and Trimble Business Center, 3D model software, installation, etc.

The BIM+digital construction technology is used in the whole process of the airfield construction. TrimbleBC-HCE software converts the BIM model of the airfield digital construction into a recognizable format of the engineering machinery control system, and releases it to the modified excavator, bulldozer, grader, roller, paver and dump truck control system through the site GNSS base station system. These digital construction machines can read drawings, guide operators or directly and automatically complete construction tasks. It is worth mentioning that through the 3D paving control system, one site surveyor can manage three pavers, instead of the traditional way, each paver needs two or three surveyors. It takes three months from the beginning to the end of asphalt paving. Six pavers operate Trimble PCS900 paving control system and use Trimble SPS930 universal total station for positioning.

It is not difficult to see from the above case of Tianbao digital construction that Tianbao has also held the firm technical key both at home and around the world. Starting from the end and looking at the present from the perspective of the future, we can see that the digital transformation has posed a problem to the construction enterprises, and at the same time, it is the digital era that has given a generous gift to the leaders of the construction industry. Entering the construction machinery industry is a process of exploring the unknown. The road to success can never be straight, but winding. In particular, we need to be patient with these disruptive innovations that may bring about major breakthroughs and create great value.

All major breakthroughs of Tianbao have gone through such patient waiting. The unit time is not years, but ten or twenty years. At present, the construction machinery industry is facing an unprecedented development opportunity, and intelligent construction machinery and digital construction will become the rigid demand for development. The intelligent development trend of construction machinery is industry driven and has broad prospects and inevitability in national economic construction. As a pioneer in the field of automatic control and digital construction of construction machinery, Tianbao will continue to provide users with high-quality products and global leading digital construction solutions.Editor/Xing Wentao

Comment

Praise

Praise

Collect

Collect

Comment

Comment

Search

Search

Write something~