- Autonomous actuator fully encapsulates the hydraulic system, ideal for high force applications where space is limited

- Variable speed pump drives reduce hydraulic system energy consumption by 80% thanks to cyclic nature

Rexroth's autonomous actuators offer two advantages. As a plug-and-play module, the actuator does not require a central hydraulic power unit and can be commissioned and operated like an electric motor shaft. Driven by a variable speed pump, the actuator reduces energy consumption by 80%. At the same time, the actuator exploits all the physical advantages of hydraulic systems, such as power density, robustness and overload capability.

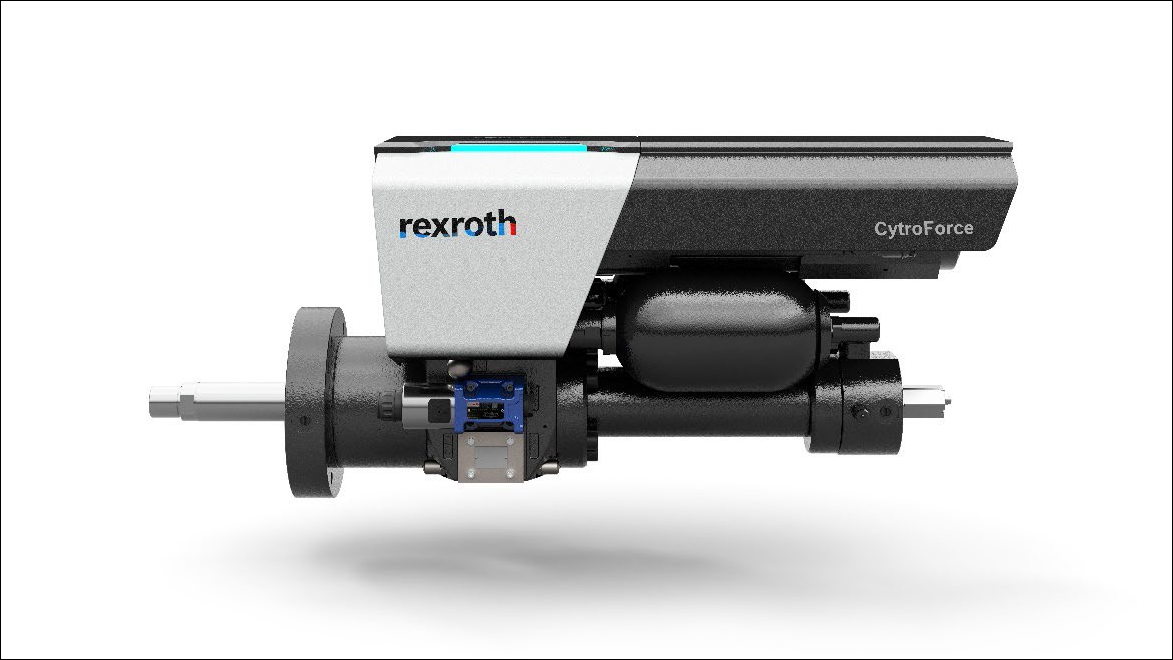

As ready-to-install modules, autonomous actuators make handling easier. The actuator is an enclosed discrete circuit which eliminates the need for a central power supply unit and does not require any plumbing construction. The CytroMotion linear axis in the power range up to 6.2 kW and the CytroForce in the higher power range, are designed as modular plug-and-play units. The SHA modular system for servo hydraulic axes also supports the creation of customer and industry-specific solutions on the basis of standard components.

Autonomous actuators completely encapsulate the hydraulic system and are ideal for high force applications where space is limited. Take the example of RexrothCytroForce, which has a wider power range

Autonomous actuators set standardized interfaces and are therefore suitable for all representative control architectures. No hydraulics expertise is required for commissioning, and once the power and communication cables are connected, technicians can use the same software tools as the motor shaft to commission the autonomous actuator. The software assistant not only guides the orderly completion of various processes, but also provides suggestions for suitable parameter settings. Therefore, the commissioning time of the shaft does not exceed 20 minutes.

Even with higher power requirements, end users will benefit from a substantial increase in energy efficiency. Thanks to the cyclic nature, the variable speed pump drive can reduce the energy consumption of the hydraulic system by 80%. A pilot project for a stretching press at the TU Dresden has demonstrated that the energy consumption of die pads can be reduced by 40%. Additionally, CytroMotion and CytroForce autonomous actuators reduce fluid volume by 75% with average noise emissions of less than 75 dB(A).

Rexroth autonomous actuators set new standards when it comes to availability and reduced maintenance needs. Autonomous actuators combine the power density, robustness and overload capability of hydraulic systems with the benefits of digital transformation. Sensors detect operational status, and CytroConnect integrated software converts the data into usable information. Through the three levels of monitoring, maintenance and forecasting, Rexroth incorporates a wide range of application scenarios - from machine data visualization solutions for field mobile terminal equipment, to equipment condition monitoring solutions, extending to forecasting for performing predictive maintenance sex analysis services. Editor/Xu Shengpeng

Comment

Praise

Praise

Collect

Collect

Comment

Comment

Search

Search

Write something~