- Tianyue has a total length of 87 meters and a total weight of about 900 tons

- Tianyue is flexible in operation and can freely switch between excavation diameters of 6.53 meters and 8 meters

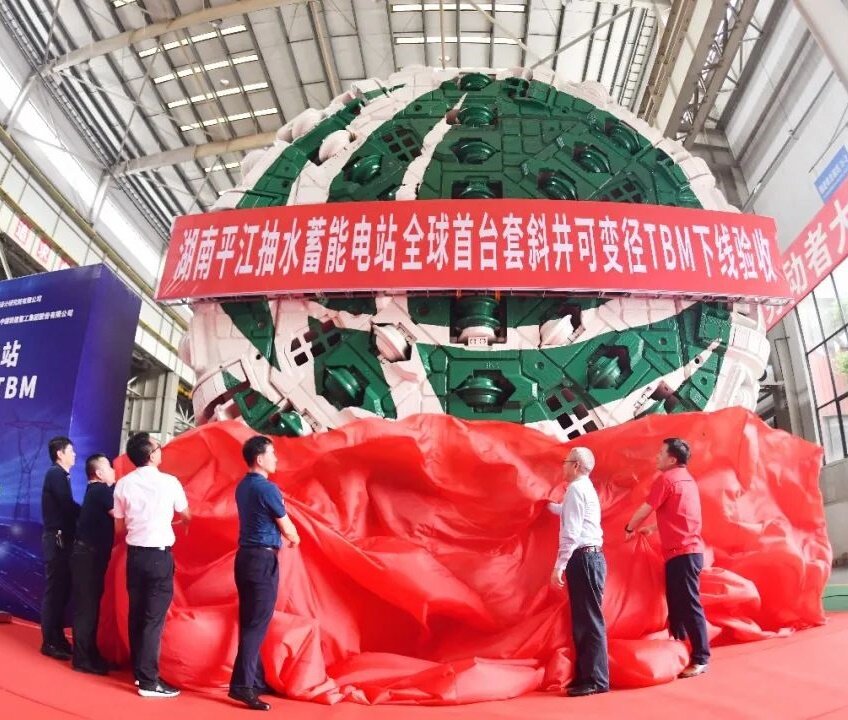

On April 20, 2023, a tunnel boring machine that can achieve 50° ultra-large slope climbing, 6.53 meters and 8 meters variable diameter excavation rolled off the production line in Changsha First Industrial Park of China Railway Construction Heavy Industry. The variable-diameter inclined shaft rock tunnel boring machine marks another new breakthrough in my country's underground construction site equipment, filling the gap in the field of full-section mechanized construction equipment for super-large slope two-stage inclined shafts in China, and further enriching the global roadheader product spectrum.

This equipment is named Tianyue, with a total length of 87 meters and a total weight of about 900 tons. It was jointly built by China Railway Construction Heavy Industry, State Grid Xinyuan Hunan Pingjiang Pumped Storage Company, and China Hydropower Eighth Bureau. It will participate in key energy projects in Hunan Province— —Construction of diversion inclined shaft project of State Grid Xinyuan Hunan Pingjiang Pumped Storage Power Station. During construction, the equipment can be flexibly transformed to realize free switching between excavation diameters of 6.53 meters and 8 meters, and it has the continuous operation capability of horizontal flat tunnels and 50-degree super-inclined inclined shafts.

Hunan Pingjiang Pumped Storage Power Station is located in Fushoushan Town, Pingjiang County, Yueyang City, with a total investment of 8.8 billion yuan, a total installed capacity of 1.4 million kilowatts, and a designed annual power generation of 1.009 billion kwh. It is the largest pumped storage power station under construction in Hunan Province. The water diversion inclined shaft tunnel is a key part of the power station construction. The height difference of the inclined shaft tunnel reaches 648 meters, which is 196 meters higher than the 452 meters tallest building in Hunan, the International Finance Center. If the traditional construction method is used, it cannot effectively deal with the complex The large climbing environment faces extremely high safety risks.

Tianyue adopts the construction method of crawling from bottom to top with a steep slope of 50 degrees, which is the first technology in the world. It can realize the full-section excavation of the two-stage water diversion inclined shaft, and the initial support can be formed at one time. Problems such as long construction period, low safety, and high labor intensity brought about by the construction method can complete more efficient, safer, and smarter inclined shaft tunnel construction operations.

The R&D team of China Railway Construction Heavy Industry made bold innovations in the design, and pioneered the configuration of multiple anti-slip systems and emergency safety assurance systems to comprehensively ensure operation safety under various working conditions. At the same time, the R&D team has overcome the problem of large-scale variable diameter of the cutter head and shield body, which has expanded the diameter range of the roadheader to 1.5 meters; It is suitable for continuous excavation in flat tunnels, inclined shafts, and turning sections, which greatly improves the engineering adaptability of equipment construction.

In order to speed up the construction of the pumped storage power station and help achieve the double carbon target, during the construction process of the project, vigorously promote the new concept of green and intelligent construction of mechanized manpower reduction, automation replacement, intelligent and unmanned, and actively build the pumped storage power station roadheader Application demonstration heights. In the construction of inclined pumping wells, the average monthly footage of the traditional drilling and blasting method is about 40 meters. After using the roadheader, the monthly progress can be increased to 200 meters, which greatly reduces the safety risk of construction workers and realizes zero explosives. Application, Tianyue has injected new impetus into the mechanization, green and digital construction of China's pumped storage power station projects.Editor/Ma Xue

Comment

Praise

Praise

Collect

Collect

Comment

Comment

Search

Search

Write something~