- The world's first double-structure hard rock roadheader is the largest open-type hard rock roadheader in China

- China Railway Equipment lays out the industrial chain around the innovation chain, providing an important guarantee for the safe and healthy development of the roadheader industry

Innovation is the first driving force for development. The development practice of China Railway Equipment under China Railway Industry has proved that only innovators advance, only innovators are strong, and only innovators win!

Since the first compound earth pressure balance shield machine with independent intellectual property rights "China Railway No. 1" rolled off the production line in 2008, breaking the monopoly position of overseas brands in the field of shield machines, now the order for shield machines exceeds 1,500 sets, and exports In more than 30 countries and regions around the world, China Railway Equipment has always adhered to the road of independent innovation and development. Through the combination of government, production, learning, research and application, it has formed 22 internationally leading core technologies and successfully developed the world's first horseshoe shield. The world's largest hard rock tunneling machine "Caucasus", the world's largest cross-section combined rectangular pipe jacking machine, the world's first full-section hard rock shaft tunneling machine and other innovative products that fill the gaps in the domestic industry have become internationally influential tunnel boring machines machine company.

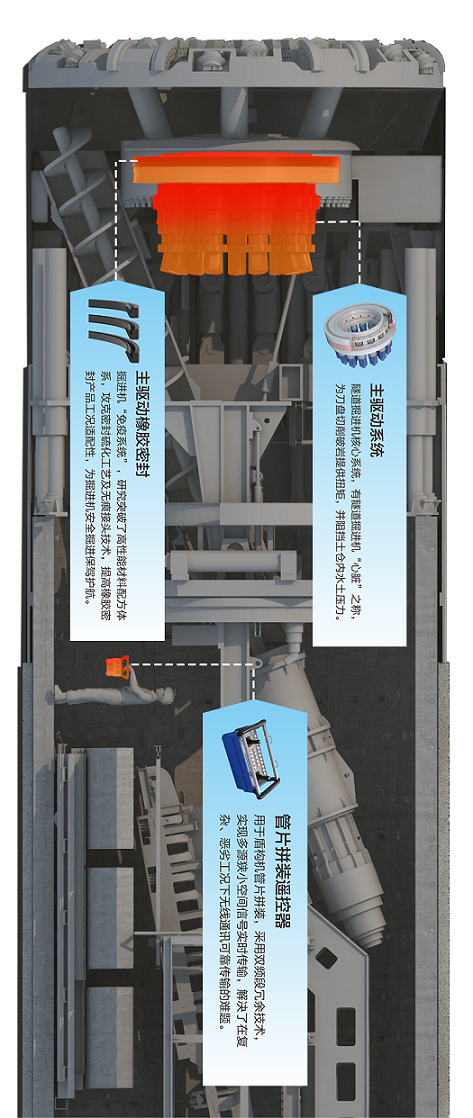

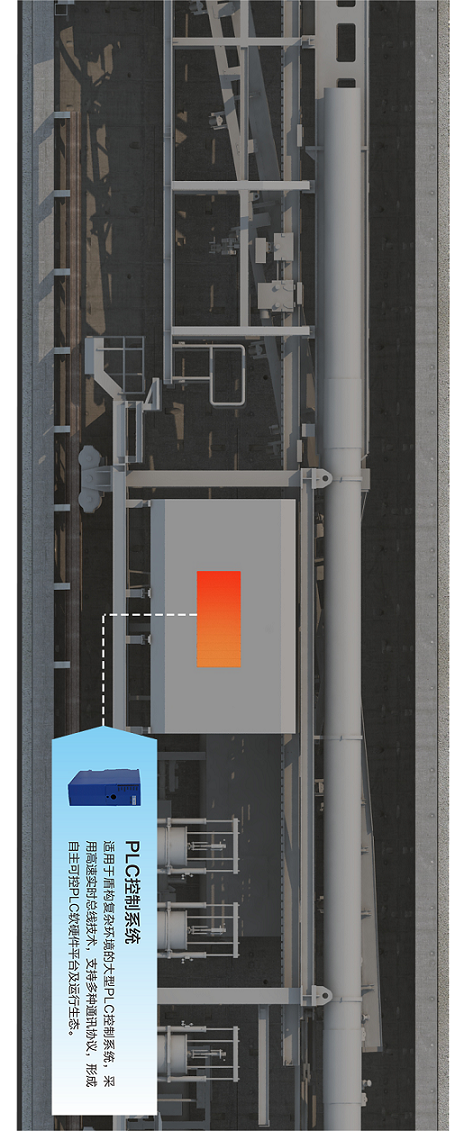

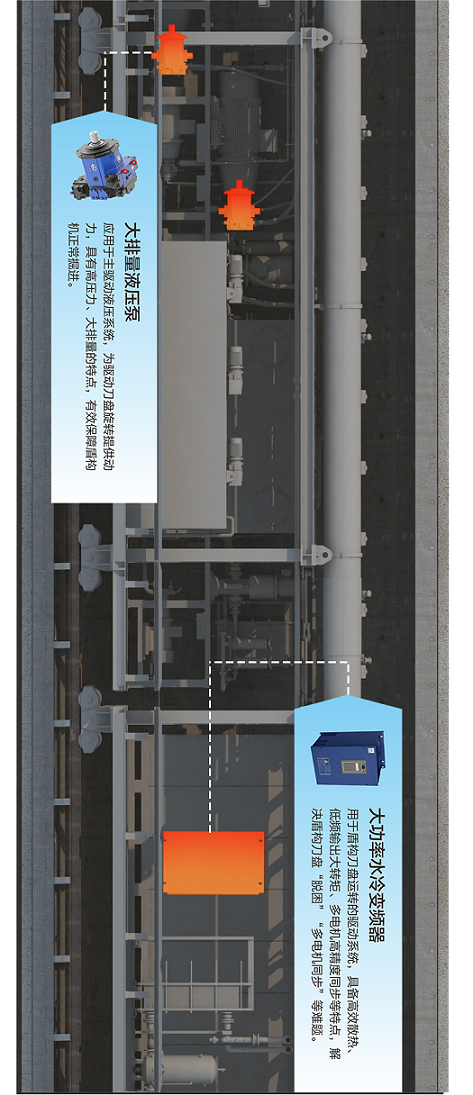

China Railway Equipment has laid out the industrial chain around the innovation chain, promoted key core technology breakthroughs, made breakthroughs in many key technologies of core components such as 3-meter-diameter main bearings, large-displacement hydraulic pumps, rubber seals, PLCs, and frequency converters, and realized the independence of core components The development and application provide an important guarantee for the safe and healthy development of the roadheader industry.

Gui Neng No. 1

The world's first mine-used small-turn full-face hard rock roadheader

The equipment is integrated with the advanced drilling rig system to realize "every excavation must be explored" in coal mine roadway construction; the "V-shaped" propulsion cylinder arrangement is innovatively adopted, and the minimum turning radius is only 45 meters, which further improves the mechanization and intelligence level of coal mine construction in my country .

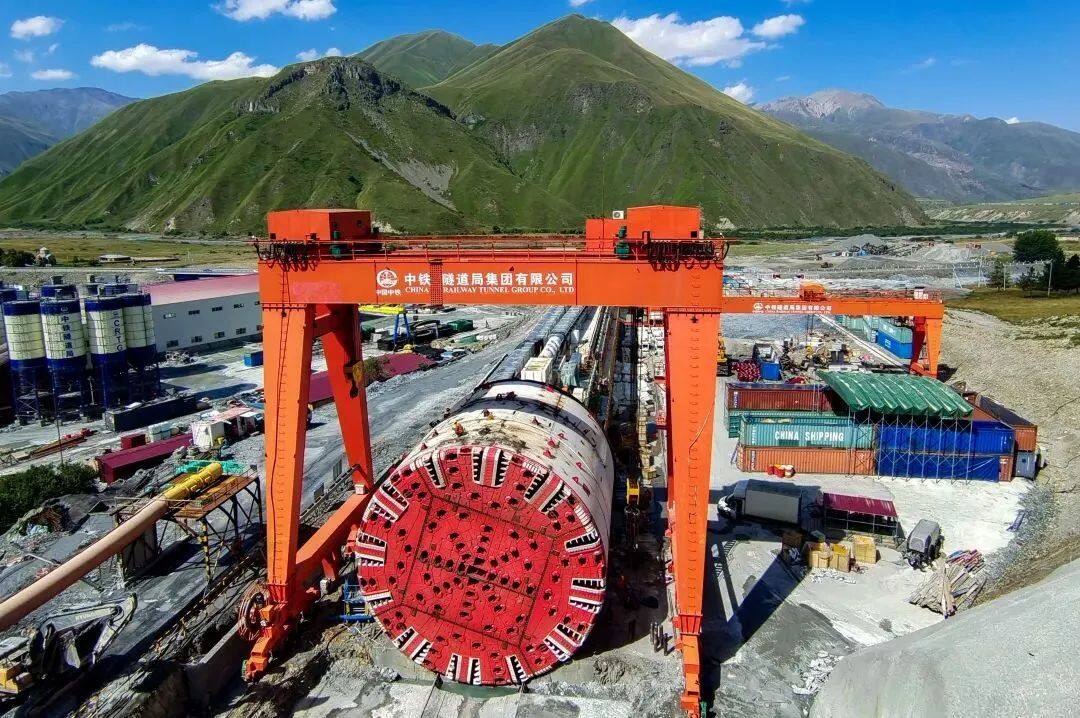

Snow Pioneer

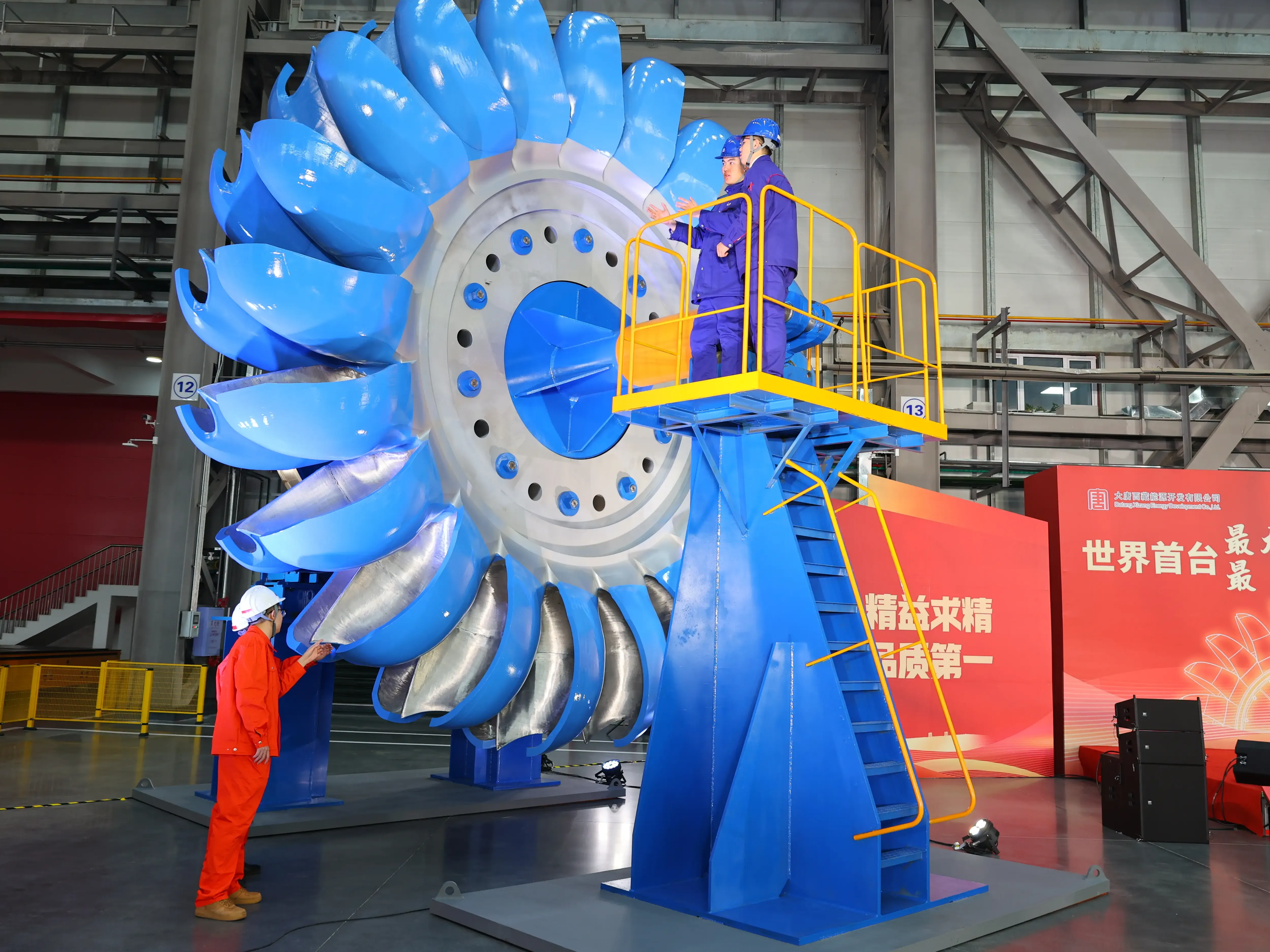

The world's first dual-structure hard rock roadheader

This equipment is currently the largest diameter open-type hard rock roadheader in China, and it is also the world's first double-structure hard rock roadheader with an excavation diameter of 10.33 meters. According to the construction site conditions, the design team added functions such as auxiliary propulsion on the basis of the traditional open TBM design concept. By optimizing the detailed design, the safety, adaptability and reliability of the equipment were greatly improved.

Dayu Tunneling

The world's largest section combined rectangular pipe jacking machine

The equipment is 11.29 meters wide and 13.55 meters high. It is composed of two pieces of equipment up and down. It adopts multi-cutter arrangement and adopts micro-step excavation technology to realize the excavation functions of shallow covering, large cross-section, and zero gap, effectively ensuring It has ensured the safety and efficiency of project construction, and filled the gap in the construction of mechanized subway underground excavation stations in my country.

Caucasus

The world's largest diameter hard rock boring machine

This equipment is currently the largest single-shield hard rock tunneling machine in the world, with an excavation diameter of 15.08 meters. For a series of construction problems such as long distances, large buried depths, and strong rock hardness, the super-large-diameter single-shield TBM active articulation system, two-speed reducer system, and large-diameter TBM synchronous pushing technology are adopted to achieve equipment in different geological conditions. It has good tunneling ability under all conditions.

Tongcheng Pioneer

The world's first large-section rectangular curve pipe jacking machine

The equipment has a width of 11.52 meters and a height of 7.22 meters. It adopts a compact host design suitable for curves as a whole, and is equipped with a posture intelligent control system for curve jacking and a low-disturbance excavation system, which ensures safe and efficient excavation of the equipment and fills large The gap in the construction technology of pipe jacking with rectangular curve in cross section is of great significance to promote the innovation and development of pipe jacking method for rectangular pipe jacking.

Wendeng

The world's first ultra-small turning radius hard rock roadheader

This equipment is the world's first compact and ultra-small turning radius hard rock roadheader. It integrates the common technology of modern hard rock roadheaders and adopts advanced technologies such as composite shield body and integrated belt conveyor to realize TBM miniaturization, Modular. The equipment is suitable for rock tunnels with a turning radius of not less than 30 meters and a rock strength of not more than 200 MPa. It has the advantages of good safety, high excavation efficiency, and flexible transition.

excursion number

The world's first hard rock mud water balance push shield machine

The equipment innovatively adopts the design concept of "pipe jacking + shield machine", which combines the technical advantages of pipe jacking machine and shield machine. The excavation diameter is 3.68 meters, which can effectively meet the non-excavation, small diameter, Special requirements such as long distances and curved jacking are of great significance for improving the mechanization level of urban underground pipe network construction.

Funing

The world's first large-diameter ultra-small turning tunnel boring machine

The excavation diameter of this equipment is 9.53 meters, the minimum turning radius is 90 meters, and the maximum design longitudinal slope is 10%. Rock breaking, stable excavation, rapid support, avoid over-excavation and under-excavation, and greatly improve the quality of cavern construction.

SBM shaft boring machine

The world's first full-face hard rock shaft boring machine

The equipment is developed based on traditional shaft construction technology combined with tunnel boring machine technology. The excavation diameter of the equipment is 7.83 meters, which can effectively meet the mechanized and intelligent construction requirements of new shafts, and is helpful for improving construction speed, ensuring personnel health, and helping energy conservation Emission reduction, etc. have a positive effect.

Meng Hua

The world's first large-section horseshoe shield machine

This equipment is the first application of the horseshoe-shaped shield construction method in the field of railway mountain soft soil tunnels in my country. It has formed a super-large cross-section horseshoe-shaped shield design and construction technology with my country's independent intellectual property rights, and realized the autonomy and intelligence of special-shaped shield equipment. High-end equipment enters the international market to provide a strong demonstration of engineering applications.

CTR450 Boom Tunneling Machine

The world's largest longitudinal axis cantilever roadheader

The equipment is 21 meters long, 4.1 meters wide, and 5.1 meters high. Its cutting power, single positioning cutting range, and weight of the whole machine all set the world record for cantilever roadheaders. The equipment is innovatively designed with a telescopic cutting arm with a maximum elongation of 1.2 meters, which is the first in the world, and the cutting area has been increased by 20%.

Xiongan

The world's first green assembled U-shield tube machine

The equipment innovatively integrates shield tunneling and erecting pipes, and realizes the integrated and efficient construction of comprehensive pipe gallery transportation, excavation, support, excavation, erection, and side seam filling, bringing technology to the mechanized construction of prefabricated comprehensive pipe gallery new breakthrough. Editor / Zhao E

Comment

Praise

Praise

Collect

Collect

Comment

Comment

Search

Search

Write something~