- The third gravel section of the well was drilled to a depth of 5,068 meters using air drilling technology

- The average daily footage of air drilling is 119.08 meters, and the average ROP is 6.69 meters per hour

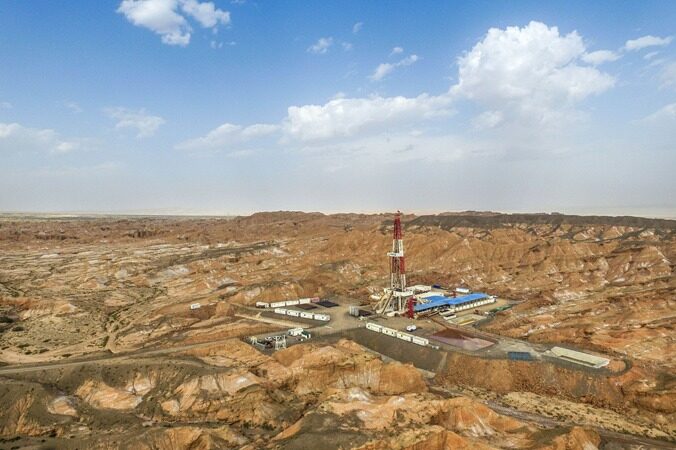

It is reported that on May 20, 2023, the Tarim Oilfield Bozi 1-2 well completed the air drilling task safely and efficiently. The third gravel section of the well was drilled to a depth of 5,068 meters by using air drilling technology, which broke the domestic 333.4 mm wellbore air drilling in one fell swoop. The deepest well on record.

It is understood that the Bozi 1-2 well is a development well deployed in the Bozi-Dabei gas region, the largest ultra-deep condensate gas field in my country. Different from foreign oil and gas reservoirs with medium and shallow normal pressure of 1,500 meters to 4,000 meters, Bozi-Dabei gas reservoirs are generally buried in ultra-deep layers of seven to eight kilometers underground, and the geological structure is extremely complex. In the vertical direction, in addition to the thick gravel layers as hard as diamonds, there are also complex and difficult-to-drill formations such as complex salt-gypsum layers and strong abrasive reservoirs. Conventional drilling techniques are risky, slow and costly.

In order to overcome the bottleneck problem of speed-up drilling in extremely thick gravel layers, the Tarim Oilfield has strengthened drilling engineering technology research and innovatively adopted air drilling, a revolutionary speed-up technology, to accelerate the advance to ultra-deep underground layers.

Different from conventional drilling, air drilling technology replaces conventional drilling fluid medium by compressing air. The almost weightless compressed air column can greatly change the stress state at the bottom of the well, and can generate a wide range of low stress areas in front of the drill bit, making the hard rock formation underground It is easier to break, and has many advantages such as increasing the ROP, saving drilling costs, and protecting oil and gas layers.

During the drilling construction period, Tarim Oilfield continued to optimize the drilling speed-up template on the basis of air drilling, which helped the well to run at a speed of 100 meters in the ultra-deep underground layer, with an average daily footage of 119.08 meters and an average mechanical speed of penetration of 6.69 meters per hour. The drilling cycle is 36 days.

Air drilling has shown its talents in this well, providing an important practical basis for promoting the advancement of air drilling technology in my country and helping to increase the speed and efficiency of extremely thick gravel layers. With the continuous improvement of drilling technology, air drilling technology is expected to release greater potential.

It is reported that the Tarim Oilfield plans to drill more than 60 new wells in the Bozi-Dabei gas region. At the same time, the application of air drilling technology will be popularized in more wells, further accelerating the exploration and development process of the Bozi-Dabei trillion cubic meter gas area, and promoting the rapid production increase of the gas area at an average annual growth rate of one million tons. Editor / Xie Li

Comment

Praise

Praise

Collect

Collect

Comment

Comment

Search

Search

Write something~