- The project is located in Wuzhai Township, Yongshan County, Zhaotong, Yunnan Province, with steep terrain and extremely harsh climate

- The project plans to install 11 wind turbines with a single capacity of 6 MW, with a total installed capacity of 66 MW

At 17:20 on May 20, 2023, as the No. 1 wind turbine in Laolu Liangzi of Datang Yunnan Dianzhong New Energy Division slowly rotated, it marked that the project's 11 wind turbines realized full-capacity grid-connected power generation.

The project is located in Wuzhai Township, Yongshan County, Zhaotong City, Yunnan Province. It is one of the key projects in Yunnan Province, with a total installed capacity of 66 MW. After it is put into operation, it is estimated that the annual on-grid electricity will be 160 million kWh, which can satisfy more than 60,000 families of three. One year's domestic electricity demand can save 50,700 tons of standard coal, reduce carbon dioxide emissions by 136,000 tons, and reduce sulfur dioxide emissions by 26.15 tons, which is equivalent to afforestation of 19,000 mu. The environmental protection benefits are remarkable.

10 years ago, the road here was thorny and sparsely populated. The first batch of Datang builders carried equipment on their shoulders and carried wooden sticks in their hands, and marched hard on the vast plateau, where they sowed the first fire of Zhaotong's new energy construction, and built the city's first wind farm in two years-- Dapingzi Wind Farm. Ten years later, the Dianzhong New Energy Division followed the pace of the pioneers, opened roads in the mountains, built bridges in the water, explored boldly, and continued to open up a new world with wisdom, courage and sweat. A single spark illuminates the Wumeng Mountains.

Foundation pouring is a confrontation between will and severe cold

Laoluliangzi project is a combination of plateau, high cold and high altitude, with extremely steep terrain and extremely harsh climate. Here, the extreme low temperature reaches -20.1°C, rain, snow and freezing weather occur frequently, and the weather conditions are very harsh. After the project started, the first hurdle the staff faced was the harsh environment. Alpine hypoxia, 8-month-long snow seasons and repeated epidemics, construction workers frequently left the site due to symptoms such as palpitation, shortness of breath, dizziness, and insomnia in just one month.

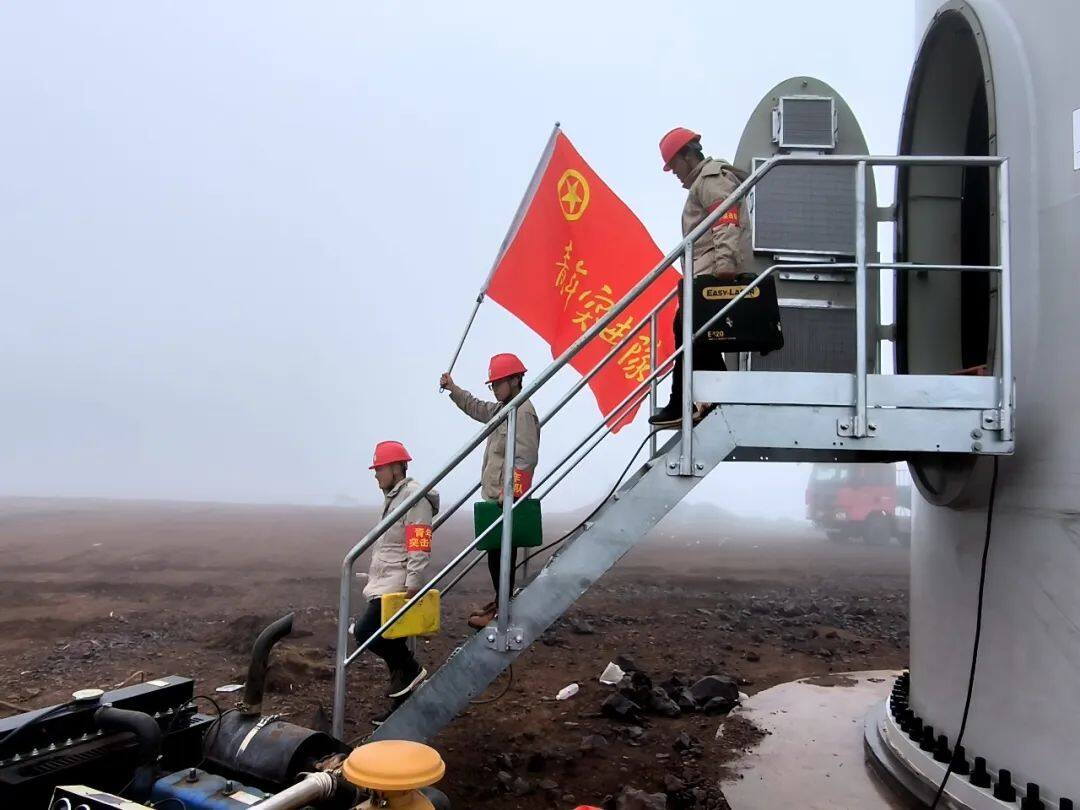

In the face of the shortage of professional technical personnel and data personnel, and the difficulty of breaking the fan base due to carelessness, the project department established a vanguard team of party members and a commando team of members. The project department coordinated the transportation vehicles of the mixing station to ensure continuous concrete pouring Pouring special personnel to survey the line and investigate the line situation. The temperature at night is as low as minus ten degrees. They also insist on going to the site to plan the feeding location, setting up checkpoints and meeting platforms along the way, and feeding back the dynamics of the transport vehicles in real time, and responding to emergencies. Timely disposal, strict control of vehicles entering the site, and full participation in pouring guarantee to ensure timely pouring.

Brother Tibetan, who herds cattle, said that he always saw these young people watching day and night. It was too cold. These children really worked too hard. Even the local old bones like us can’t go up the mountain at night. What’s the matter? I survived. The Laoluliang Subproject Department completed all the wind turbine foundation pouring work in only 56 days, surpassing the plateau wind power construction acceleration.

Large-scale transportation is the intersection of responsibility and the future

The diameter of the impeller of the 6 MW fan used in this project reaches 192 meters, which is currently the plateau mountain wind turbine with the longest impeller diameter in China. The access road is 70 kilometers long, passing through three towns and ten villages, with steep slopes, narrow roads, and many curves. Residential power lines are intricate, and the transportation of large components faces huge challenges such as roadblocks and air barriers. It is unimaginably difficult to transfer these behemoths to designated aircraft positions.

In order to complete the project on time and with high quality, the business department set up a special team to coordinate with the local government, transportation bureau and other functional departments to upgrade and renovate 112 rural roads. "I drove a loader on the construction site when the project started, and I got a lot of salary every month. In 2023, my family plans to use the road built when transporting the blades to sell the loquats in the village to the city." Participated in the construction of the wind power project A villager in Zhongzhai Village said. "It used to take three or four hours to walk from home to school. In 2023, it will only take more than an hour for children to go to school. It will be much more convenient to study," said a villager in Baiyun. Today, an avenue connects the scenery along the road, connects the wealth road leading to the outside world, and even becomes a highway for children to go to school.

Hoisting operation is a struggle of strength and weight

On the plateau at an altitude of more than 3,000 meters, extreme weather hits frequently, and there is still heavy snowfall in Liangzi, the old road in May. How to make this steel giant with more than 120 tons of wheels alone stand up smoothly has become a huge challenge. Faced with many difficulties such as harsh hoisting conditions and extremely short effective construction window period, safety control is the top priority.

The project department held several special meetings to make sufficient preparations before hoisting, research and compile a special hoisting construction plan, and unlock the single-blade hoisting plan, which greatly prevented the lateral load from exceeding the lateral resistance of the crane and ensured Lifting safety. The project team adheres to the work philosophy of high standards, strict requirements, and detailed implementation, and carefully organizes and plans. Through the construction organization work such as the construction plan of one fan and one proposal and the safety technology disclosure of one fan and one disclosure, during the hoisting process, the operators are Carry out strict safety technology disclosure, strict inspection of hoisting equipment spreaders before hoisting, strict surrounding inspection and monitoring, actively organize all participating units to refine various tasks in accordance with the requirements of grid-connected nodes, formulate feasible work plans, and carry out daily Dynamic tracking management, careful and meticulous checks for each security defense line, and grabbing the window period to carry out crane transfer and hoisting work under safety permitting conditions. It only took 48 days from the first unit to the grid to the last unit's hoisting.

Preliminary work is the reward of dedication and hard work

The personnel of the project department braved the wind and snow to measure the wind speed, stepped on the iron shoes to find the plane, and worked on the topic day and night. "My project colleagues and I like our current identity - new villagers in Wuzhai. When it comes to the topography of the mountain, even the old people in the village may not be familiar with me." In order to facilitate the work, the project department staff ate in the village , live in the village, and occasionally have free time to help fellow villagers plant potatoes or cut grass. The trunk of the project department’s car is always filled with various components, switches, sockets, light bulbs... When they receive calls for help, they always follow the appointment And to. Ten minutes of maintenance and chatting in the fields have built a bridge of connection with the masses. They have changed from the "leader" that everyone said when they entered the village to the "brother" and "big brother" today; Xi Mo will last forever" (Yi language: asking a man if he is in love) the words are fluent in the answer. With a good mass base, the project completed the preliminary resource exploration work in a very short period of time, and the land acquisition work involving 3 villages with a total area of 13 hectares was completed in just over 80 days.

Those who do not seek change will advance, and those who do not seek refuge will succeed. The full investment of the old road and Liangzi is only the first step in the Long March. Dianzhong New Energy Business Unit will devote itself to creating high-quality plateau projects in the photovoltaic and wind power new energy industries, helping to build a clean, low-carbon, safe and efficient energy supply system, and striving to become the second largest project of the group company. The vanguard on the road to entrepreneurship. Editor/He Yuting

Comment

Praise

Praise

Collect

Collect

Comment

Comment

Search

Search

Write something~