- Gem Machinery pioneered an independent root system with parallel operation mode

- This mechanical equipment can realize one-button operation of key equipment and process flow in oil and gas exploration and development drilling operations

On May 20, the State-owned Assets Supervision and Administration Commission of the State Council issued the "Product Manual of Scientific and Technological Innovation Achievements of Central Enterprises (2022 Edition)", which involved core electronic components, key components, analysis and testing instruments, basic software, key materials, advanced technology, and high-end equipment 7 A total of 369 scientific and technological innovation achievements in various fields. PetroChina has 10 scientific and technological innovation achievements selected.

The one-button human-computer interaction 7,000-meter automatic drilling rig successfully developed by PetroChina Gem Machinery can realize one-button operation of key equipment and technological processes in oil and gas exploration and development drilling operations; Operations such as threading, cleaning, and thread oil application are fully automated; root establishment and drilling operations are performed simultaneously.

Drilling rigs are mainly used in the fields of petroleum and natural gas exploitation and geological exploration, and have the remarkable characteristics of high automation, high operating efficiency, high safety level and excellent control performance. The drilling rig has drilled 2 wells with a cumulative footage of over 15,000 meters, creating 4 drilling records in this block. The "two seats control the whole process" of drilling operations has been realized, the crew configuration of the drilling team has been reduced by 1/3, the labor intensity has been reduced by 90%, the tripping speed has been increased by 25%, and the intrinsic safety level has been greatly improved.

The drilling rig has been rated as the first (set) of major technical equipment by the National Energy Administration and PetroChina, and has been mass-produced. It will make an important contribution to the efficient and low-cost exploration and development of oil and gas in my country.

Baoshi Machinery successfully developed a "one-button" human-computer interaction 7000-meter automatic drilling rig, which broke through technical bottlenecks such as multi-equipment linkage and collaborative control, pioneered an independent root system with parallel operation mode, and broke through key points such as virtual reconstruction and visual recognition. Technology, developed an intelligent safety management and control system, established a platform for online monitoring and remote operation and maintenance of drilling rigs, and realized "process automation, fewer people in operations, and one-key control".

How much do you know about "one-button" drilling rigs?

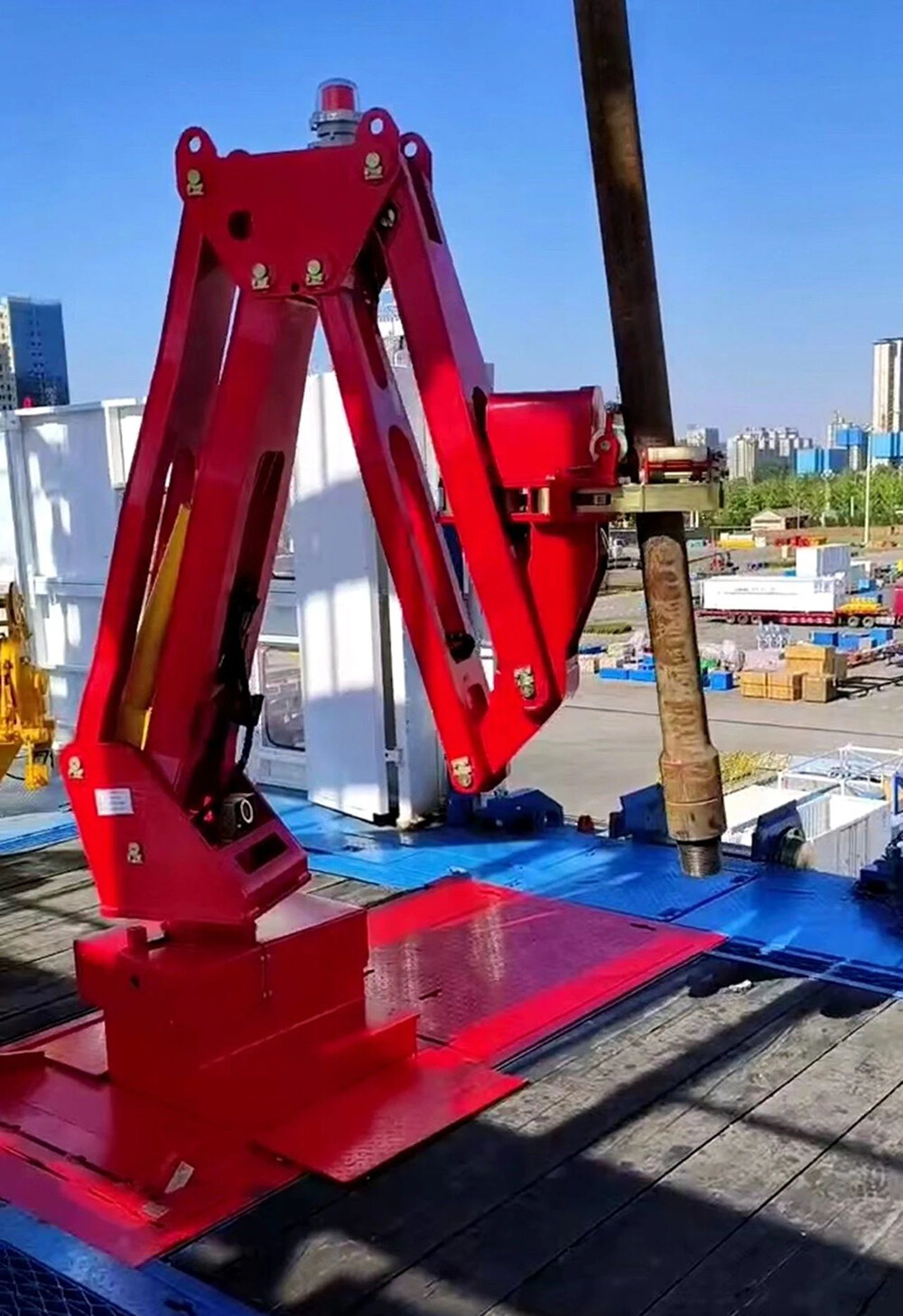

Power rack

The power rack adopts hydraulic synchronous control technology, which can meet the requirements of multi-layer drilling tool discharge and reverse transportation, realize unmanned and automatic storage yard drilling tool transportation and recovery operations, and greatly reduce the labor intensity of field workers.

Yard pipe string lifting device

The yard pipe string lifting device is a new type of ground pipe string handling automation equipment, which can complete the automatic transportation of drilling tools from the ground pipe row area to the catwalk. A maximum of 6 layers of drilling tools can be placed, which is especially suitable for the limited area of the well site, realizing the non-rolling transportation of the pipe string, and solving the problems of high labor intensity and poor safety of manual auxiliary operations on the site of the well team.

power catwalk

The power catway adopts electro-hydraulic control and automatic remote operation technology to realize the automation of drilling tool transportation, which can solve the problems of low efficiency and poor safety of drilling tool transportation on site by the well team, especially in casing running and drilling Collars, throwing drilling tools and other operations.

iron driller

The iron driller can realize the automatic loading and unloading operations of drilling tools at the wellhead and rat hole positions, and at the same time integrates auxiliary functions such as stabbing, application of thread oil and mud blowout prevention. It solves the problems of manual assistance, low degree of automation, and high risk of wellhead operations in the process of root establishment, making-up and breaking-out of drilling tools, etc.

Handling manipulator

The pipe support manipulator adopts sinking or L-shaped offset, which can completely avoid the channel of the pipe stand when it is not working. One-button automatic and precise discharge is realized through remote control, which solves the problem of relying on manual pushing and supporting operations for the well crew to stand up and throw single roots on site, and greatly reduces the labor intensity of manual operations.

Two-story platform pipe arrangement

The pipe arrangement device of the second-story platform can solve the problem of pushing and supporting the upper end of the vertical root and relying on manpower during the on-site tripping of the drilling team. The second-story platform derrick worker is transferred to the driller's room, which greatly improves the operating environment and realizes the unmanned operation of the second-story platform. Completely reduce the risk of working at heights.

Integrated Control System

The integrated control system adopts the design concept of "function multiplexing, one-key multi-function, and human-computer interaction" to realize fully integrated operation of each equipment of the drilling rig, unified management of information, dynamic connection of processes, and intelligent safety control. Editor / Xie Li

Comment

Praise

Praise

Collect

Collect

Comment

Comment

Search

Search

Write something~