- Lovol LT160 equipment exclusively uses the customized WP17 engine, showing strong and flexible power performance as a whole

- According to the national standard, the gradeability of the mine rigid mine car is greater than or equal to 25.4%.

The earth rumbled, and mine carts rushed to and fro. In "The Wandering Earth 2", which will hit the fire in 2023, the densely woven giant minecarts continuously provide mineral fuel for the huge planetary engine, supporting the long journey of human beings to explore the boundless universe; The vehicle construction machinery industry also supports the "rapid advance" of China's industry and is one of the important guarantees for the stable development of China's economy.

The prosperity of the mining industry leads to the prosperity of the industry, and the stability of the industry leads to the stability of the economy. As an important member of Lovol Heavy Industry Group, Lovol Vehicles is well aware of the importance of the independent development of mining trucks and construction machinery for China's industry, and also understands that only with excellent products and leading technologies can it break the monopoly of European and American companies for a long time The right to speak in the market.

After three years of hard work, relying on forward-looking development plans and deep technical reserves, Lovol Vehicles has built a full series of 100-ton wide-body mines with a tonnage of 100-160 tons under the two-way empowerment of "Weichai + Lovol Heavy Industry" The car has realized the upgrade and iteration of the domestic wide-body mining truck!

Among them, LT120, LT130 and LT160 are the three "mining weapons" that are most popular with industry customers. They not only achieved steady sales growth in the domestic market, but also expanded their footprints in Russia, Vietnam and other important overseas markets.

Gold allocation, stimulate powerful potential energy

On the outdoor test field with the roaring sound of the machine, a series of dynamic tests before leaving the factory are in full swing. With the blessing of the "Weichai engine + Fast gearbox + Hande axle" mining truck gold power system, Lovol The LT series 100-ton wide-body mine trucks have performed excellently in many power test projects.

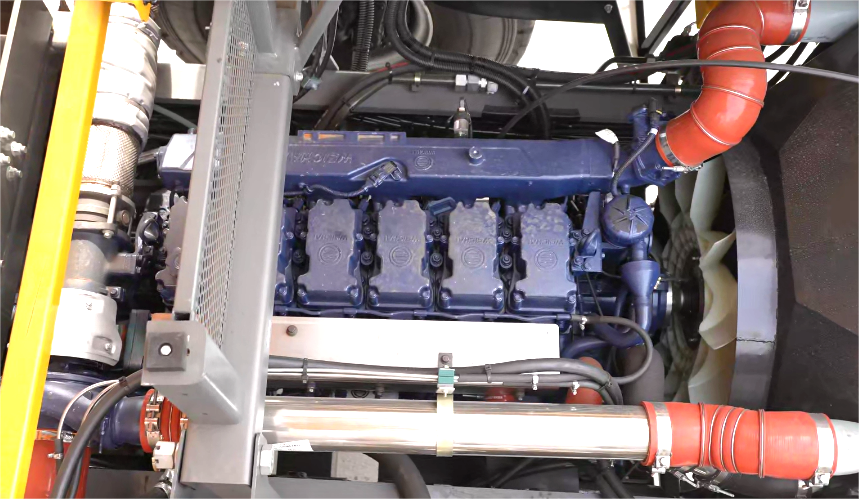

Taking Lovol LT160 with the largest tonnage as an example, the equipment exclusively uses a customized WP17 engine, and its power output is as high as 770 horsepower. Flexible power performance, even in the demanding factory heavy-duty climbing test, it also performed brilliantly.

"The gradeability of rigid mine trucks in mines is greater than or equal to 25.4% according to the national standard road, while our test is nearly 30%. Our control standard is to be as close as possible to commercial vehicles!" Lovol engineer in charge of the on-site test has confidence in the equipment beyond words.

Powerful and stable core power, combined with a 55-square-meter super-large cargo box, enables the Lovol LT series of 100-ton wide-body mining trucks to bring customers a huge increase in output value of "more loads, lower costs and higher income", while reducing the required The number of equipment and labor costs; while the Lovol LT series of 100-ton wide-body mining trucks do not require a urea post-treatment system and the dual advantages of optimized fuel consumption further reduce the cost of equipment use, making the Lovol LT series a 100-ton dump truck for mines The economy is the most preferred.

"High efficiency and low cost" is the eternal theme of mining equipment, and it is also the focus of iterative upgrading of Lovol vehicle products. The cost of use has become the "dream car" for many domestic mining customers to get rich and start a business.

Ingenuity and meticulous work to create a new benchmark for durability and reliability

Compared with power performance and transportation efficiency, whether mining vehicles have a more stable attendance rate and durability is more concerned by mine customers, and Lovol also works meticulously in this regard, polishing every detail with ingenuity.

"Since we specialized in mining vehicles in 2019, we have improved the chassis. In addition to using more solid materials, we have successively corrected more than 300 minor problems and minor problems, and modified the connection structure of the frame, effectively improving the attendance of the equipment in practical applications. Judging from the evaluation of old customers, I am very satisfied with the rate and load-bearing capacity.” Looking at the vehicle passing through the Belgian road and the twisted road, which highly tested the structural reliability, Lovol engineers listed them one by one: “At the same time, the rear door beam of the cargo box and the The optimization of the longitudinal beam structure also avoids collision and cracking during loading or unloading.”

Through the application of original patented technology and fine modification of key components, the engineers of Lovol mine trucks have solved the common pain points of wide-body dump trucks, such as frame cracking, frequent breakage of front suspension leaf springs, and force bar breakage. It effectively guarantees the stability of the vehicle and greatly improves the equipment attendance rate in complex real working conditions, which is particularly reflected in the design of the LT160.

"In the development of the 160, in addition to benchmarking key components such as the engine and gearbox with first-class brands, we also applied some of our own original patented technologies. First, we adopted a double-slider structure for the front suspension design to cope with the bumpy road conditions in the mining area. ;At the same time, in order to solve the reliability problem of the water tank in the mining area, we redesigned the connection between the heat dissipation structure of the water tank and the frame, which is also one of our patented technologies!"

While continuously promoting the improvement of equipment quality with technology and ingenuity, the efficient and professional customized after-market service solutions provided by Raywater for different customers have also become one of the important guarantees for equipment attendance. In recent years, Lovol has established a one-stop mine service network in major provinces across the country with the aim of "problems never stay overnight", relying on a mature and professional technician team, standardized process flow, professional technical support, and fast and timely spare parts supply. Practice the service concept of "creating greater value for customers" with actions.

Demand-oriented, light up the safe and comfortable experience

When the mine truck is driving on the extremely bumpy washboard road, people with a little experience will sweat for the safety of the internal parts of the equipment and the driver, but the engineers in Lovol are not at all worried about this.

"According to all aspects of mine road conditions, we will use customized auxiliary designs to adapt to it. In terms of driving safety, we will pass equipment leakage and anti-rollover tests to ensure the safety of the driver to the greatest extent; In the past, during driving, the bolts of the thrust rod of the rear suspension often broke due to bumps, and we will replace them with a pin-type structure to reduce the possibility of breakage and damage.”

Safety is as important as Mount Tai, and driving comfort is also essential for drivers who have been fighting on the front line all year round. "For the car that came over now, we replaced the traditional leaf spring structure with an oil-pneumatic suspension, which not only reduces the vehicle's driving bumps, but also makes the driver more comfortable. It also has a protective effect and makes the vehicle transportation more stable and safe."

Skills can be seen in the square inch, and the truth can be seen in the subtleties. Relying on the fine control of key accessories and solid materials regardless of cost, Leiwote vehicles have formed unique design and technical advantages in terms of equipment safety, reliability, and durability, effectively solving the worries of mine users about the safety of transportation equipment .

As the roar of the vehicles faded away, the Lovol LT series 100-ton wide-body mining trucks on site have successfully completed the test, and the performance data of each vehicle will be recorded in the corresponding electronic files. All records are recorded together to provide data support for vehicle maintenance and key component maintenance.

As an important pioneer of Lovol's product strategy, the Lovol LT series of 100-ton wide-body mine trucks will become the backbone of Lovol's mine truck product lineup in the future, and will drive all Lovol mine trucks to form a joint force to realize the Lovol mine truck. Car's corporate ideal of "establishing a new benchmark for wide-body mining trucks and leading the large-scale mining equipment"! In the future in China and the global market, Lovol vehicles will be deeply integrated with Lovol excavators and other supporting equipment to provide customers with integrated mine construction equipment product solutions with high cost performance and high performance. Editor / Zhao E

Comment

Praise

Praise

Collect

Collect

Comment

Comment

Search

Search

Write something~