- More incentives for solar module manufacturing will be an ideal choice to make Indian solar modules more cost competitive globally

For Gautam Solar, an Indian manufacturing company, the country's push for renewable energy is creating huge opportunities for it to expand its business scale. It began manufacturing solar modules and then expanded to more complex solar panel production. We started manufacturing solar modules because we recognized the enormous potential of renewable energy, especially solar energy in India, and catered to the growing market, which was flooded by Chinese solar modules, "said Shubhra Mohanka, director of Gautam Solar.

This New Delhi company is one of the beneficiaries as India has increased its efforts to manufacture more critical components that can play a crucial role in the country's transition to green energy. This includes semiconductors, solar panels, and energy storage systems. At the same time, India's goal is to achieve 500 gigawatts of renewable energy capacity by 2030 as it seeks to reduce its dependence on expensive and polluting fossil fuel imports.

Most of the country's power generation heavily relies on coal

With the rapid growth of energy demand along with economic expansion, if India wants to achieve its goal of reducing carbon emissions, including Prime Minister Narendra Modi's goal of achieving net zero emissions by 2070, it needs alternative and cleaner power sources. However, India has been heavily reliant on imported components necessary for renewable energy infrastructure, including solar panels and batteries from China. In order to achieve its renewable energy goals, the government is increasingly providing incentives for companies that manufacture key components. New Delhi is planning to provide a new $2.6 billion subsidy plan for grid battery manufacturing companies.

India is ambitious in promoting its domestic manufacturing industry, including the entire renewable energy value chain, including grid batteries, "said Vibhuti Garg, South Asia Director of the Institute for Energy Economics and Financial Analysis. These are crucial for the use of renewable energy sources, including solar and wind energy, as this type of electricity is not available 24/7 and requires storage of the generated energy to maximize its potential.

Ms. Garg said that India hoped to reduce its dependence on imports because its renewable energy ambitions and goals were hit by the supply disruption caused by Covid-19 and the Russo-Ukrainian War.

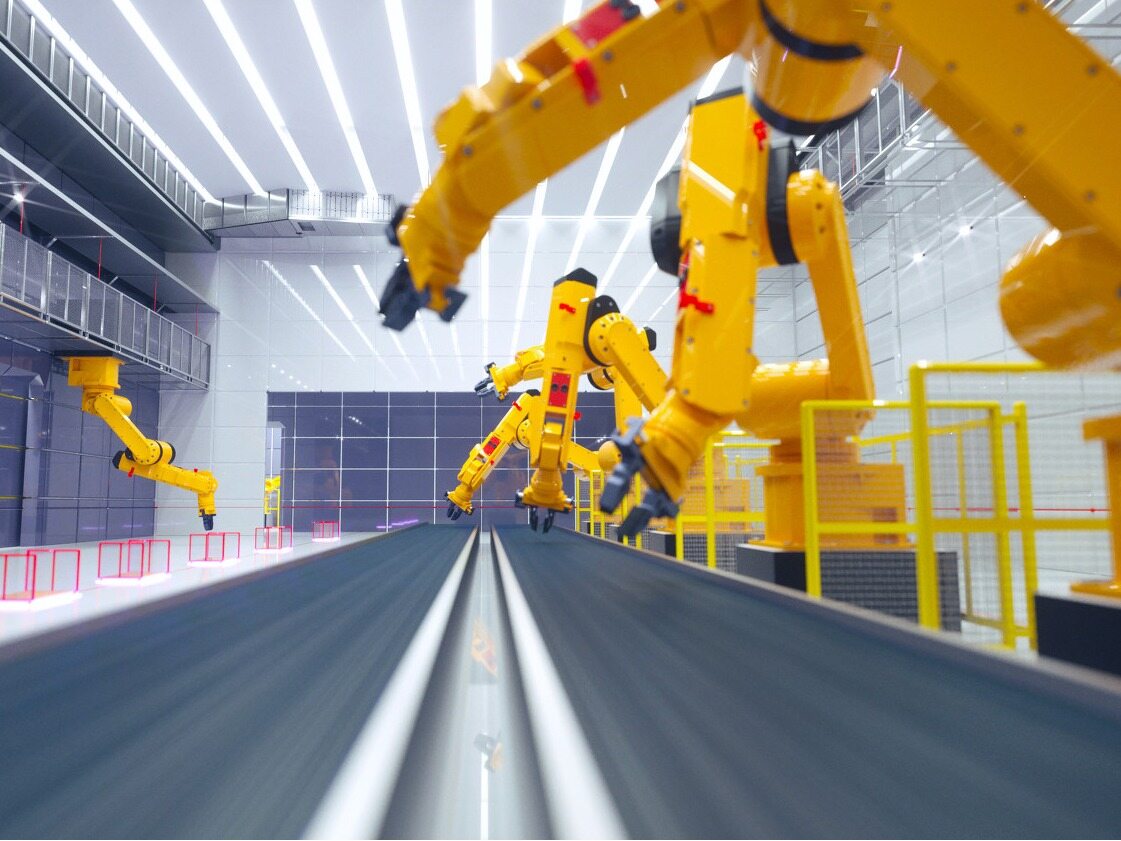

In addition, building manufacturing capacity will create more job opportunities and stimulate India's economic growth. Promoting the manufacturing of grid batteries locally will reduce costs, which may have a significant impact on the potential wider use of green energy. Currently, the rise in battery prices has limited large-scale deployment. The government expects that large-scale manufacturing capacity will help lower prices and accelerate the deployment of renewable energy, Ms. Garg said. However, the country is still in a very early stage in terms of manufacturing capacity for grid batteries, said Barnik Maitra, managing partner of Indian consulting firm Arthur D Little. There are also obstacles, including regulatory issues and environmental challenges, as the manufacturing of these batteries requires a significant amount of energy and resources. Rishabh Jain, Senior Project Leader of the Energy, Environment, and Water Commission Think Tank, stated that expanding India's battery manufacturing will take time and the country will have to cope with existing and expanding competition.

Manufacturing scale will also be an urgent issue, as the scale of global manufacturers cannot match that of Indian manufacturers for a period of time. Despite the challenges, building the capacity and capability to manufacture batteries, solar modules, and semiconductors will be crucial for India's transition to clean energy and broader economic benefits, "said Mr. Maitra.

The government's India Manufacturing Plan aims to make India a global manufacturing hub as the world's most populous country strives to accelerate economic growth and create more job opportunities. In addition, India has managed to significantly increase the production of solar panels in recent years, partly due to providing manufacturers with incentives related to production.

Ms. Mohanka from Gautam Solar stated that Indian solar panel manufacturers can receive some subsidies, which are a huge driving force for domestic solar module manufacturing. The main obstacles to India's solar module manufacturing are access to financing, a shortage of skilled labor, and technological and infrastructure limitations, "said Ms. Mohanka. The interest rate in the domestic renewable energy market ranges from 8% to 10%, while in the Western market it ranges from 3% to 4%.

Although India is manufacturing more solar panels, it still relies on China to import components including initial processing of solar cells and polycrystalline silicon. However, experts say the progress is enormous and encouraging. If India can expand its domestic manufacturing scale in the coming years, it can not only meet domestic demand, but also supply the world and strengthen the global supply chain of solar modules, "said Mr. Jain of CEEW.

India also hopes to become a center for semiconductor manufacturing and exports, one of its benefits being to help local electric vehicle production in the country. Chip manufacturing in India is still in its early stages. However, significant progress was made in June. Micron, an American chip manufacturer, said it would invest as much as 825 million dollars to build a semiconductor packaging and testing facility in the western state of Gujarat.

Further support from the central and state governments in India will result in a total investment of 2.75 billion US dollars. This news was announced during Modi's visit to the United States in June.

In May, India restarted the application process for a $10 billion incentive plan to encourage chip manufacturing. The manufacturing of key components in India, especially semiconductors, is of great significance for the electric vehicle industry, "said Visakh Sasikumar, founder of the Indian electric vehicle ecosystem platform Fyn Mobility. By producing these components domestically, India can reduce its dependence on imports, enhance supply chain elasticity, accelerate the widespread adoption of electric vehicles, and thus drive the country's economy towards a cleaner and more sustainable future. The localized manufacturing of chips can help reduce the production costs of electric vehicles, thereby reducing consumer costs.

India's plan to increase the output of semiconductor, grid cells, solar modules and other components is really ambitious, said Nitin Rakesh, professor and dean of the Department of Computer Science and Engineering at the University of Grand Noida Sharda near New Delhi. Although India has resources, capabilities, and political support, there are still challenges in areas such as supply chain, infrastructure, technology, and capacity development, "said Professor Rakesh. India has made progress, but it is important to recognize that establishing a strong domestic manufacturing ecosystem will take time.Editor/XingWentao

Comment

Praise

Praise

Collect

Collect

Comment

Comment

Search

Search

Write something~