- The residential building machine is based on the super high-rise public building aerial building machine above 300 meters

On July 14, 2020, China's first "residential building machine" independently developed by China Construction Third Engineering Research Institute and China Construction Third Engineering Corporation was successfully applied in Chongqing Zhongjian·Yuhu No. 1 Project. It takes only 80 minutes to raise a floor and grow 3 meters in height, creating a new speed in the field of house construction.

"It took 13 years from the construction of fully manual steel pipe scaffolding to the development of the "airborne construction machine" in the public construction field, and then to the "residential construction machine"." Technology Development Department, Engineering Technology Research Institute of China Construction Third Engineering Bureau Deputy manager Wang Lei introduced that this "residential building machine" has a weight of 270 tons, which can be used for vertical structure and floor slab construction at the same time. Compared with the "air building machine" that can only be used for vertical structure construction, it is not only "weight-loss". More than 70%, and more practical.

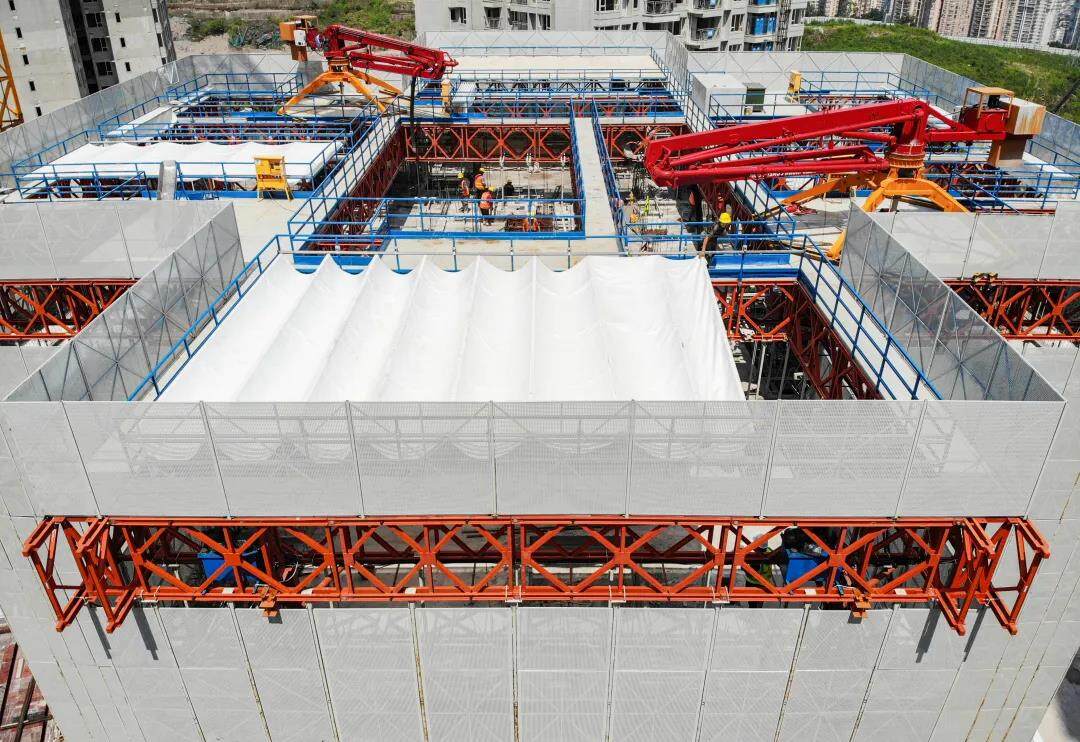

"Residential building machine" can cover 5-8 structural layers at a time. When the main structure is being constructed on the upper part of the outer frame, the bottom of the outer frame can be interspersed with decoration and other multi-process operations at the same time, becoming a sky that can grow independently with the structure. Moving factories greatly speeds up the construction cycle.

"Residential building machine" uses steel platform walkways to form 13 4-8 meter wide unit openings. Each opening is equipped with a retractable awning. During normal construction, the awning lifting materials can be opened; when the rainy weather is coming, the rain can be closed at any time The awning covers the rain; in high temperature weather, the awning can be closed and the spray device can be turned on to cool down. Regardless of wind and rain, high sunshine, the working layer can provide a closed working environment all-weather, providing workers with a more comfortable and user-friendly working environment, basically meeting the conditions of “wind and rain” on-site construction, forming a “panoramic aerial production line ".

Intelligent production efficiency

The brand-new "residential building machine" has many new explorations and breakthroughs in terms of hard core functions. Compared with the previous technical construction methods, it has stronger adaptability, higher integration, faster speed and better quality.

First, the "residential building machine" uses a light-weight external wall fulcrum, which can flexibly select the location of the fulcrum and lay the platform for different structural systems, and be used in the construction of different residential structures. Most of the equipment materials adopt the assembly node design, and the recycling turnover rate is more than 90%. In the next commissioning, only a small amount of non-standard components need to be assembled, and the conversion rate is higher. The industrialization promotion prospect is worth looking forward to.

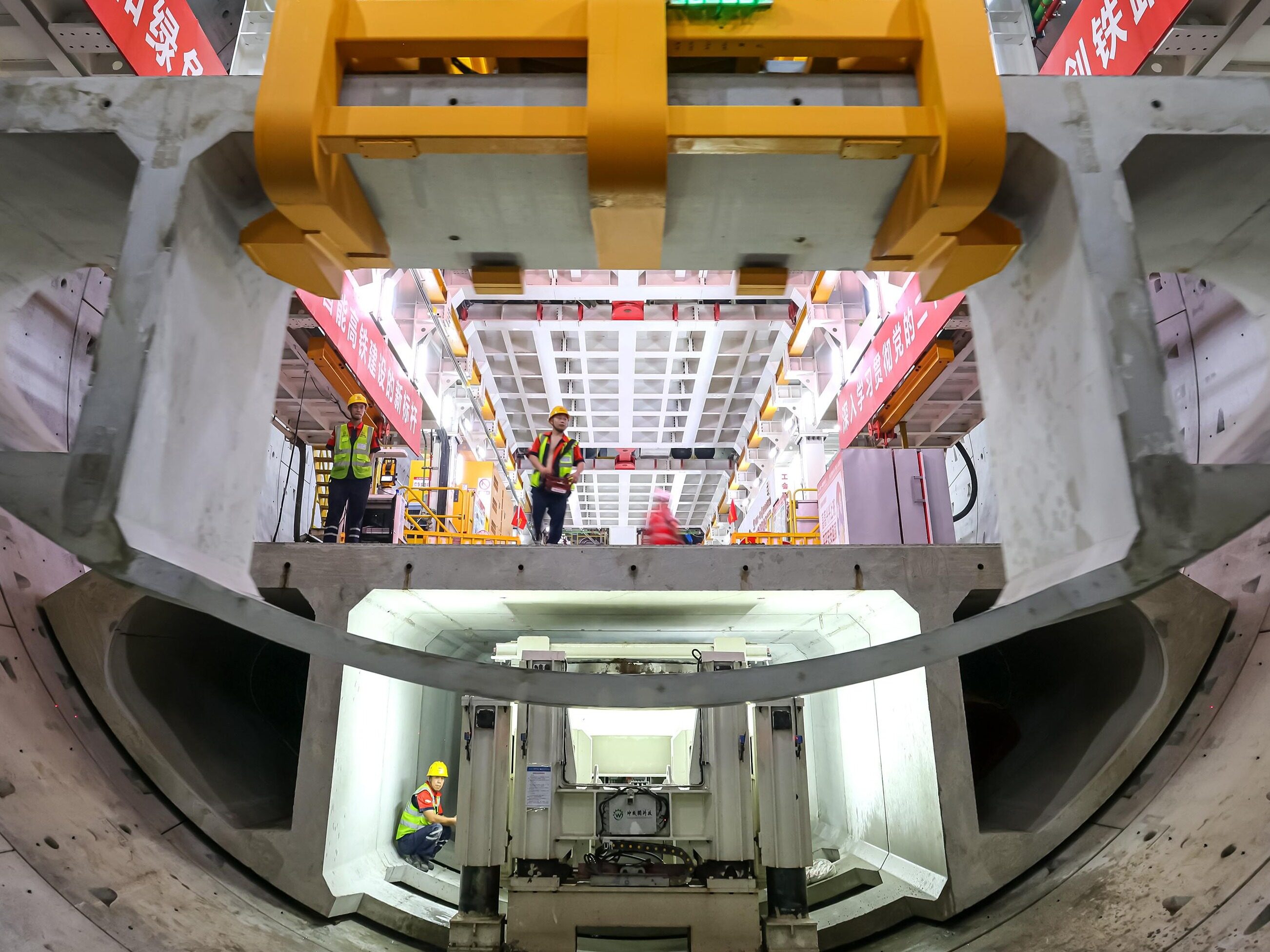

Secondly, the way of "climbing up" has also changed a lot, from the previous "rock climbing" high-power, long-stroke jacking to a small-cylinder "stepped" short-stroke jacking, the project has realized a building machine A working floor height is raised from 80 to 90 minutes, and the construction speed can be as fast as one floor in three days, which is much faster than before.

Third, it has a higher degree of integration. For the first time, the top canopy equipment, the peripheral vertical formwork, and the cloth machine are all climbed at one time. The operation frame, formwork, work tools, and power distribution box can also be placed in the platform to achieve simultaneous upgrades. , Reduce material turnover, reduce burden for workers, save a lot of labor costs, and more convenient to use.

Fourth, in terms of intelligence, residential building machines can feed back real-time data to the control center through displacement sensors to achieve automatic system correction and higher safety. The seemingly large and complicated equipment system only needs one manager to start in the control room with one key, and 5-6 workers can do safety inspections, which greatly saves labor.

Leading the future of the industry

"Residential building machine" is suitable for ordinary super high-rise residential and public building fields, such as: residential, office, hotel and other projects.

Compared with the traditional climbing frame, although the one-time cost of the "residential building machine" has increased, the cost sharing advantage is very obvious. In the process of national urbanization, the land use in the central urban area is tense, and there are more and more super high-rise residential buildings. The construction technology of residential building machines is more in line with the future development of the industry. Editor/Peng Xue

Comment

Praise

Praise

Collect

Collect

Comment

Comment

Search

Search

Write something~