- China Railway Group will contribute more to the construction of the Guangdong-Hong Kong-Macao Greater Bay Area

On October 28, 2020, Shenzhen Urban Rail Transit Line 2 Phase 3, Line 3 Phase 3, Line 4 Phase 3, and Line 8 Phase 1 of Shenzhen Urban Rail Transit, jointly constructed by China Railway Open. So far, the operating mileage of Shenzhen's subway has exceeded 400 kilometers, reaching 411 kilometers. China Railway Group has added a strong touch to the blueprint of Shenzhen's urban rail transit construction.

The third phase of Shenzhen Metro Line 2 starts at Xinxiu Station and ends at Liantang Station. The length of the line is about 3.78 kilometers and there are 3 stations along the way. The first phase of Shenzhen Metro Line 8 starts at Wutongshan South Station and ends at Yantian Road Station. It is about 12.36 kilometers long and has 6 stations along the way.

After the third phase of line 2 and the first phase of line 8 are opened, the two lines will realize seamless connection and operation of the two lines. There is no need to get off and transfer during the whole journey, and the transfer time will be greatly saved.

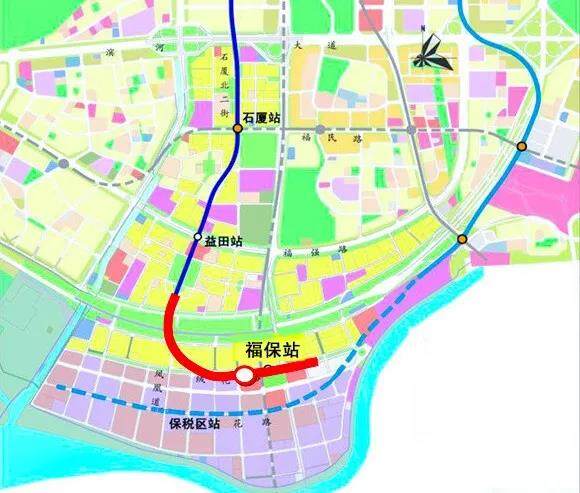

The third phase of Shenzhen Metro Line 3 starts at Yitian Station on the existing line and extends south to Futian Free Trade Zone. There are 1 station and 1 section with a total length of 1.45 kilometers. After completion, it will realize the direct subway network of Shenzhen Futian Free Trade Zone, with convenient transportation. Sex is greatly improved.

The third phase of MTR (Shenzhen) Line 4 is one of the important projects of Shenzhen-Hong Kong cooperation and development. It is an important rail transit trunk line connecting Shenzhen Longhua and Guanlan areas through Futian Central District and Shenzhen North Sub-center, with a total length of 10.8 kilometers There are a total of 8 stations, a new Guanlan parking lot, and a new Changkeng main substation.

In the construction of the third phase of MTR (Shenzhen) Line 4, the participating units of China Railway Corporation adhered to the concept of "building a subway is building a city", learned the advanced management concepts of MTR, carefully organized, scientifically constructed, and completed it at a high level. The construction of the third phase of Metro Line 4 will contribute to the development of urban rail transit in the Shenzhen Special Economic Zone and the interconnection of the Guangdong-Hong Kong-Macao Greater Bay Area.

The Guanniu Section and Songguan Section of the MTR (Shenzhen) Line 4 Phase III project have complex stratums and need to penetrate buildings at a short distance. The section tunnels are buried deep, the radius of the circular curve is small, the geology is complex, the groundwater is abundant, and the construction is difficult. Big.

China Railway Group has successively invested 6 shield machines in the construction, and actively carried out technical research, scientifically set shield tunneling parameters, tunneling speed, grouting parameters, and strengthened the management of various processes such as muck improvement to ensure that the shield tunneling process does not change tools. The construction unit strictly controlled the quality of shield tunnels with small curve radius from five aspects: curved tunnel shield tunneling, segment prefabrication, quality control outside the tunnel entry, segment assembly control in the tunnel, and quality control after assembly. The improvement of the quality and appearance of shield tunnel segments with small curve radius forms a complete set of shield tunnel construction technology for small radius curve sections.

Guanlan Parking Lot is one of the largest subway train parking lots in Shenzhen underground rail transit. It covers an area of 145,000 square meters and has a total construction area of about 115,000 square meters. It can park up to 24 subway trains at the same time. It will be together with the Longhua Depot Undertake the functions of parking, maintenance and repair of the subway trains of Shenzhen Metro Line 4.

During the construction process, the project department innovated work ideas, through the use of BIM5D technology, automated slope monitoring technology, rotary drilling bored pile construction technology, integral mobile lantern rack technology, tower crane spray technology, automatic air duct processing technology and other new Technology and new technology have effectively improved construction quality and construction efficiency. Editor/Peng Xue

Comment

Praise

Praise

Collect

Collect

Comment

Comment

Search

Search

Write something~