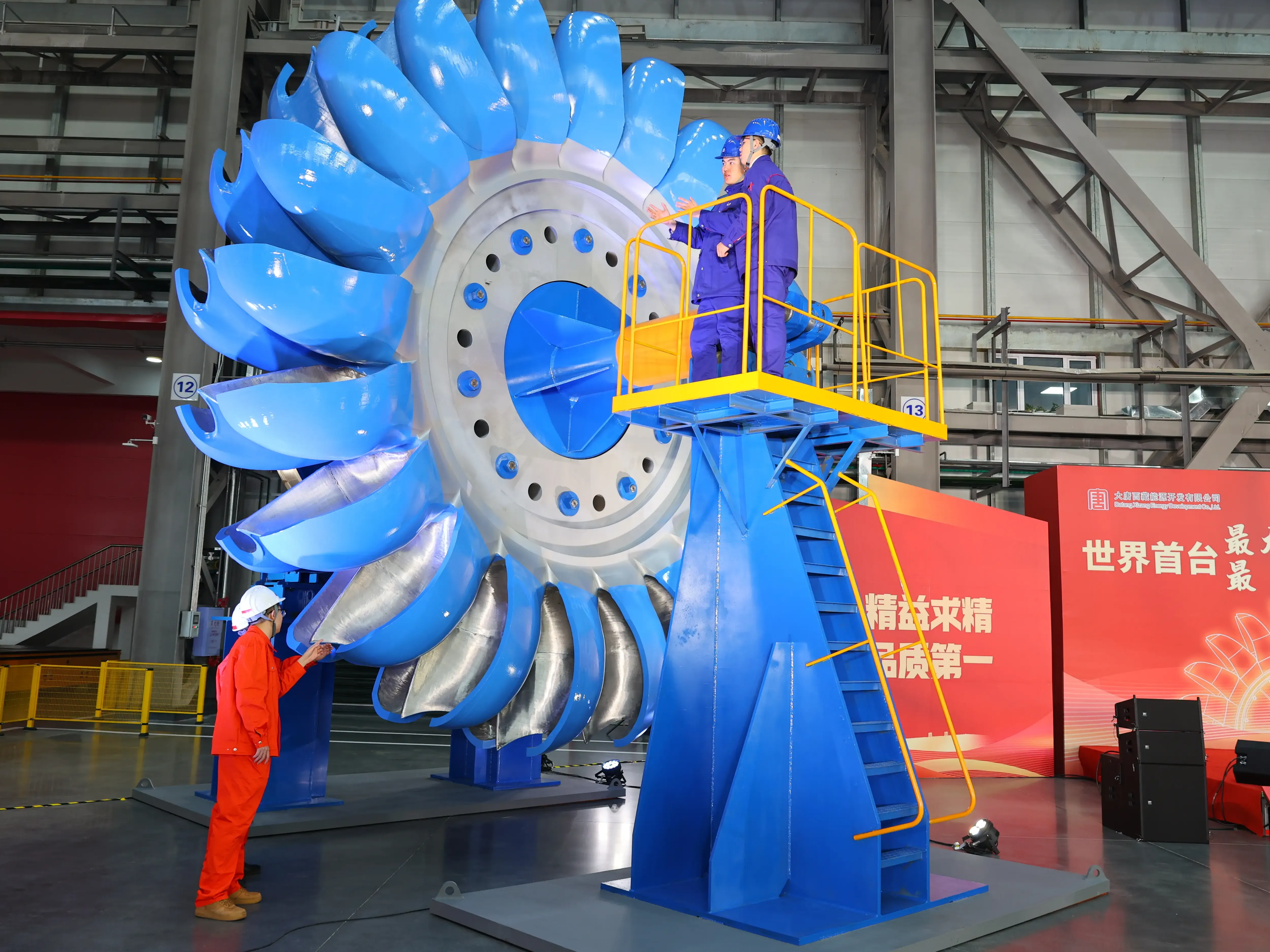

- BYD's new product series of handling robots-AC20DP is derived from ingenuity and loyal to the original intention. It is for you

After several years of grinding, combined with years of manufacturing experience, a new generation of intelligent handling robot AC20DP was born, with high efficiency and energy saving, faster speed, more sensitive movement, higher safety performance, and the working status of the machine, customers are in control.

High precision: Lidar detects scenes and obstacles, creates a map in real time and corrects the position of the robot, effectively planning the trajectory to avoid obstacles.

High safety: Non-contact safety design, using laser scanners, ultrasonics, etc., used alone or in combination to identify surrounding obstacles, remote detection; safety control, speed monitoring, emergency stop, multiple strategies to make different choices for different working conditions, Improve safety performance; sound and light alarms, warning horns, and warning lights, to a greater extent, improve the safety of the robot; when the machine touches the edge, it will stop automatically when it touches an obstacle.

Remote operation: The remote control can be used to remotely control the vehicle to realize one-to-many operation (a remote control connects multiple vehicles).

Dispatching system: With the vehicle dispatching system, it can monitor and control all AGV on-site operating conditions, and provide real-time feedback of vehicle status information; task scheduling, task analysis, and dispatching tasks according to the task level; system docking, open system docking function, and customization Interface service.Editor/Luo Wentao

Comment

Praise

Praise

Collect

Collect

Comment

Comment

Search

Search

Write something~