- High-speed cargo sports cars are economical, fast, intelligent and efficient, safe and environmentally friendly

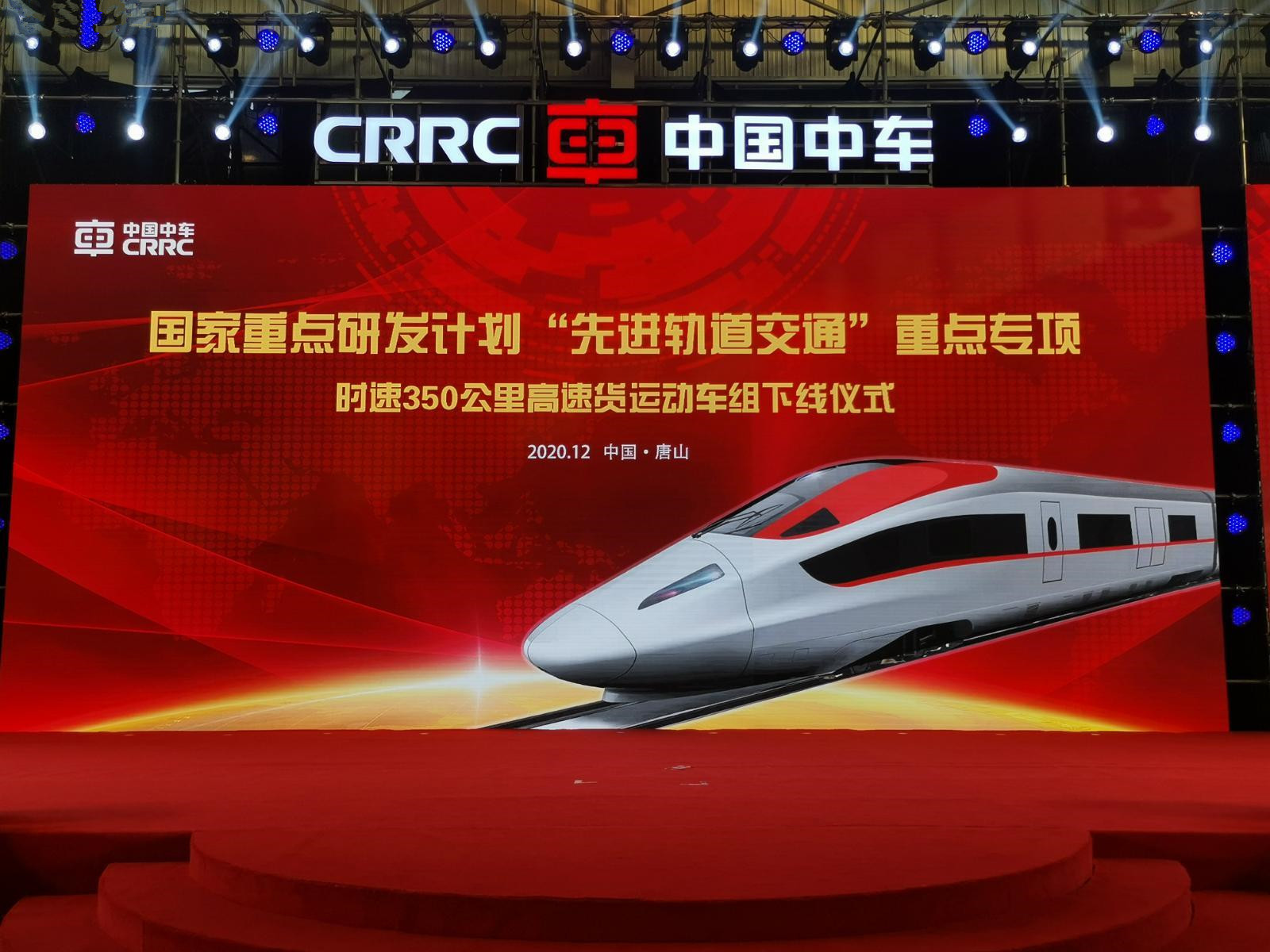

On December 23, 2020, China's 350km/h high-speed freight train was officially rolled off the assembly line at China CRRC Tangshan Locomotive and Rolling Stock Co., Ltd. in Tangshan, Hebei. It is understood that this high-speed cargo sports train with a Chinese sturgeon bone bionic front and a three-color silver-white-red through-body body has a pair of 2.9-meter-wide loading doors on the side of each carriage. This is a high-speed cargo sports train. The most notable appearance feature that is different from ordinary passenger sports cars.

According to Liang Yongting, a senior engineer of the Product R&D Center of CRRC Tangshan Company and chief designer of high-speed freight trains, the high-speed freight trains are based on China's 350 kilometers per hour high-speed train platform, which has broken through the carrying system, traveling system, intelligent loading and unloading equipment, Fast loading and unloading and many other key technologies for the rapidization of rail transportation freight, the first full range of loading and unloading equipment such as large-opening loading doors for high-speed freight trains, standard container pedigree products, and modular freight floors, significantly improving the efficiency of loading and unloading operations. Large load, large volume, fast loading and unloading and cargo in transit management.

Liang Yongting emphasized that the 350km/h high-speed cargo sports car set can adapt to the ambient temperature from -25°C to 40°C. The power configuration is a 4-motor 4-tow 8-car formation, with a load of no less than 110 tons and a cargo volume of no less than 800 cubic meters. Space utilization rate ≥85%. Compared with aviation and road transportation, the freight vehicle group is less affected by environmental factors. It can be reached within 5 hours from a distance of 1,500 kilometers, and the energy consumption per unit weight of cargo is only about 8% of that of an aircraft. It is economical, fast, intelligent, efficient, and safe. Environmental protection and other characteristics.

The high-speed freight train unit uses technologies such as big data analysis, cloud virtual stowage, precise weight control and genetic algorithms to realize the intelligent stowage of goods and the reasonable distribution of vehicle loads. Using UWB technology, mobile data network and Beidou satellite navigation technology, the precise identification and positioning of cargo and the interaction of cargo information between vehicles are realized. It meets the needs of medium and long-distance fast freight transportation in the distance of 600-1500 kilometers. It has significant advantages such as high transportation timeliness, high operation frequency, low transportation cost and all-weather operation. It is the first time in the world to achieve high-speed rail freight transportation at a speed of 350 kilometers per hour, which significantly improves China's rail transportation equipment The level of independent innovation.

In terms of safety, environmental protection and operating economy, the outer skin of the high-speed freight sports car set uses environmentally friendly water-based paint, which is environmentally friendly and has no harm to the human body and the environment during long-term application. The front design of the EMU adopts the principle of bionics and is characterized by the linear shape of the Chinese sturgeon, which increases the front slenderness ratio. The wind tunnel test proves that the head shape is dynamic and beautiful, while significantly reducing the operation compared with the existing models. resistance. The EMU is equipped with an intelligent fire alarm system, applying a variety of new fire-retardant materials and technologies. The warehouse area uses a new intumescent fire-retardant coating, and the fire-proof layer has a service life of more than 10 years.

Under the key special support of the "Advanced Rail Transit" key research and development program of the Ministry of Science and Technology of China, the 350km/h high-speed freight train is led by CRRC Tangshan Company, and the superior unit within the United Nations has carried out research and successfully developed it over three years. Editor/He Yuting

Comment

Praise

Praise

Collect

Collect

Comment

Comment

Search

Search

Write something~