- The whole line of the project is about 14 kilometers, with 20 stations, including 19 stations recently

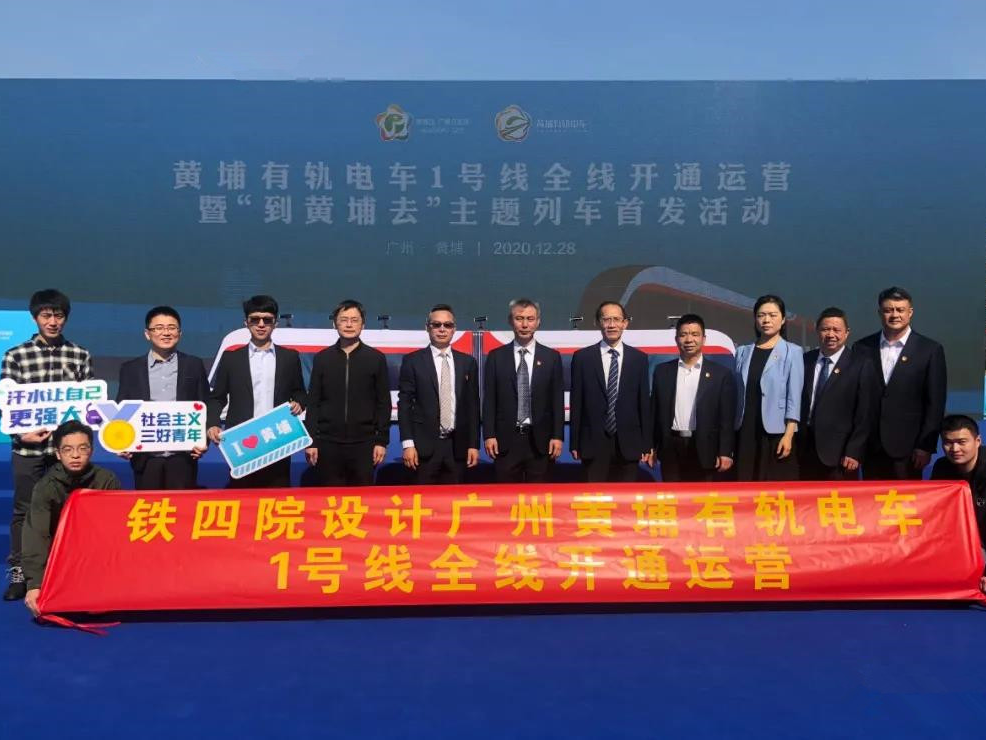

On December 28, 2020, Guangzhou Huangpu Tram Line 1, designed by the Fourth Railway Institute, was put into operation. It is understood that the tram line 1 project in Huangpu District of Guangzhou will be constructed in phases. The first section (the line is 7.83 kilometers long and has 11 stations) has been officially put into commercial operation on July 1.

Guangzhou Huangpu District Tram Line 1

Guangzhou Huangpu District Tram Line 1 (Changlingju-Luogang) starts from Xiangxue and ends at Yonghe Xinfeng. The whole line is about 14 kilometers, with 20 stations and 19 stations recently (including 1 elevated station, ground 18 stations), 1 ground station is reserved in the long term. There is a section of the whole line, the car depot covers an area of 6.58 hectares, and the parking lot covers an area of 3.25 hectares.

China's first single-layer tram station on a continuous beam with a small radius across a river

This project is the first in China to set up a single-layer tram station on a continuous beam with a small radius across the river. Both ends of the station are equipped with escalator exits. The bridge deck can be used as a platform for trams to get on and off passengers, and it can also be used for pedestrians to cross the river. Use of flyovers. The escalator entrance and exit on the north side of the station allows passengers to seamlessly transfer to the escalator entrance and exit of the subway; the escalator entrance and exit on the south side of the station and the cross-river bridge connect the subway station, the land to be developed, the tram station, and Yongshun Avenue, greatly improving The land use value.

The degree of intensification creates the highest depot in the domestic tram project

The Lingfu Depot of the project is a superstructure development complex that integrates vehicle maintenance, overhaul and civil residences. It has the notable characteristics of intensive land use and efficient overhaul. By optimizing the layout of the strands and coordinating the design schemes of the cover and the cover, the land use is highly intensive and the seamless connection of traffic is realized, and an efficient, three-dimensional and beautiful urban space and traffic corridor are created. It covers an area of only 5 hectares, which is a domestic level of intensiveness. The most tram project. Innovative maintenance technology, breaking through the limitations of traditional automatic car washing equipment land and stock road layout, and adopting the through-line car washing method under extremely restricted land conditions, which greatly improves operation efficiency, reduces labor intensity, and saves operations on average The cost is about 600,000 yuan/year.

For the first time in China, the ground-sensing coil method is used for vehicle departure detection

The information exchange between the vehicle and the charging station has always been a pain point in the supercapacitor energy storage tram project. The traditional scheme uses radio frequency code identification to perform off-station detection. This solution requires a dry battery-powered launching device to be installed on the roof of the car, which requires daily roof maintenance and has a high probability of failure.

This project innovatively uses ground induction coils and embeds induction coils in the ground, so that the off-station detection system is completely separated from the vehicle body, which can effectively identify the vehicle off-station signal. The equipment has a long life cycle, good maintenance-free and high reliability.

It is the first time in China to adopt a dual-unit charging station, a station charging station on a difficult road section, and a station charging scheme for ordinary road sections.

This project is based on the advantages of PWM rectification and is not restricted by bridge rectification, so that the two low-voltage windings of the rectifier transformer are independent of each other and supply power for different rectifier voltage regulating modules. The new scheme uses a centralized rectification and voltage regulation scheme, and there is no DC cable in the interval, allowing both upstream and downstream vehicles to be charged at the same time, and can support switching between each other.

The first domestic tram powered by supercapacitors and lithium titanate batteries

In order to solve the problems of insufficient energy storage in the long-distance section and excessive vehicle load caused by variable road conditions at level crossings, the project optimized the power supply control strategy. For the first time in China, super capacitors and lithium titanate batteries were used for power supply. The power supply system is highly matched with the vehicle energy storage device. Through vehicle traction simulation calculations, the optimal solution for the layout of charging stations is obtained under the contact-free operating conditions of the section. The installation of charging stations in some stations can realize the efficient operation of vehicles throughout the journey, reducing the investment in the power supply system by about 40 million yuan.

Guangzhou Huangpu Tram Line 1 is fully operational, which means that Huangpu District has officially entered the era of trams. Editor/He Yuting

Comment

Praise

Praise

Collect

Collect

Comment

Comment

Search

Search

Write something~