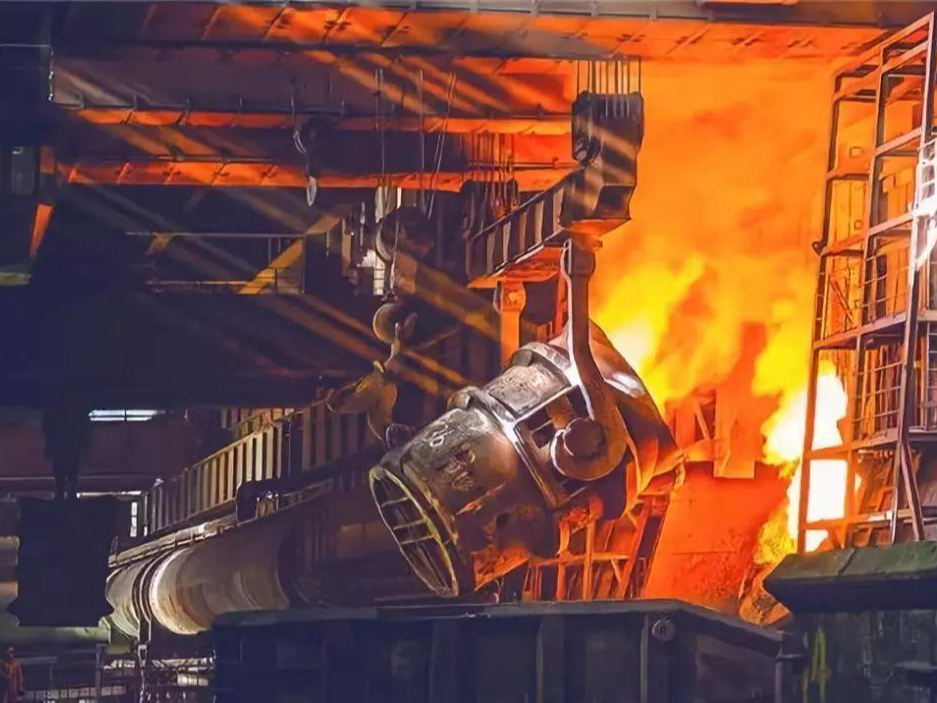

- The goal of carbon neutrality is an inescapable challenge for carbon emitters, including the steel industry.

China's carbon peak and carbon neutral target action roadmap has been clear. In this context, the "14th Five-Year Plan" period has become an important window for the steel industry to achieve low-carbon development. The steel industry is a major energy consumer and a major carbon dioxide emitter. As the world's largest producer and consumer of crude steel, China's crude steel production accounts for more than half of global crude steel production, and its carbon emissions account for more than 60% of global steel carbon emissions.

Steel production will decline year-on-year in 2021

Since 2020, China's steel production has grown strongly. In 2020, the country's crude steel output exceeded 1 billion tons for the first time, setting a record high. From January to February 2021, the national crude steel output was 175 million tons, a year-on-year increase of 12.9%.

Yin Ruiyu, academician of the Chinese Academy of Engineering, pointed out at the 2021 (Twelfth) China Iron and Steel Development Forum held recently that China's huge crude steel production has resulted in a relatively high share of the total carbon dioxide emissions of the steel industry in the country's total carbon dioxide emissions. China's steel industry should take a high-quality, reduced-quantity development path. First of all, it should not continue to increase production and cannot export large amounts of low-value-added steel.

Recently, relevant authorities have successively released policy signals to reduce steel output. Huang Libin, spokesperson for the Ministry of Industry and Information Technology, said that it will study and formulate relevant work plans to ensure a full year-on-year decline in steel production in 2021.

According to Luo Tiejun, vice chairman of the China Iron and Steel Association, the state’s proposal to reduce production capacity and limit production is conducive to maintaining stable supply and demand of resources, achieving the goal of carbon peaking and carbon neutrality, and conducive to the high-quality development and transformation of the steel industry. upgrade.

Luo Tiejun said that the iron and steel industry has taken “controlling production capacity without increasing and ensuring effective supply” as one of the key tasks in 2021. It is necessary to give full play to the role of import and export regulation. While maintaining the export of high value-added products, reduce the export of general products and increase the import of primary products such as steel billets and scrap steel.

From "relative constraint" to "absolute constraint"

On February 10, 2021, the China Iron and Steel Industry Association issued the "Proposal for Promoting Low-Carbon Action in the Steel Industry" and emphasized that the steel industry will face from the "relative constraint" of carbon emission intensity to the "absolute constraint" of total carbon emissions.

According to reports, relevant national ministries and commissions are conducting research on carbon peaking and carbon reduction action plans in the steel industry, and the Metallurgical Industry Planning and Research Institute participates in related work as a supporting unit. According to the research results of the Metallurgical Industry Planning and Research Institute, the steel industry’s carbon peak and carbon emission reduction paths include promoting green layout, energy saving and energy efficiency, optimizing energy use and process structure, building a circular economy industrial chain, applying breakthrough low-carbon technologies, Six aspects including system construction and policy system support.

"According to the research results of our institute, China's steel industry will achieve a peak in carbon emissions by 2025; by 2030, China's steel industry will reduce its carbon emissions by 30% from the peak, and it is estimated that carbon emissions will be reduced by 420 million tons." Metallurgical Industry Li Xinchuang, Secretary of the Party Committee and Chief Engineer of the Planning Research Institute, said.

The world’s largest steel company, China Baowu Iron and Steel Group Co., Ltd., announced its carbon emission reduction target in January 2021: a low-carbon metallurgical roadmap was proposed in 2021, and the goal was to achieve carbon peaks in 2023, and to have 30% carbon reduction process technology in 2025. Capacity, strive to reduce carbon by 30% in 2035, and strive to achieve carbon neutrality by 2050. At the specific implementation level, China Baowu will use technological innovation to open up the low-carbon development path of the steel industry; improve carbon utilization efficiency with intelligence and quality; optimize the energy structure and increase investment in energy-saving and environmentally friendly technologies.

As one of the world's largest steel material manufacturing and comprehensive service providers, HBIS Group Co., Ltd. has established the overall goal of "carbon peaks in 2022 and carbon neutrality by 2050", and formulated the HBIS Group Low-Carbon Green Development Action Plan. Work will be carried out in four stages: peak carbon, steady decline, substantial decline, and deep decarbonization.

Coordinate the development of new technologies and products

"Low-carbon development will have a profound impact on the steel industry, and even bring about extensive and profound revolutions in production, consumption, energy and technology, thereby reshaping the entire industry and even the economic and social development pattern." Li Xinchuang believes that China's steel industry is low-carbon. Transformation is a tough battle that must be won. Based on scientific and technological progress, the application of breakthrough low-carbon technologies is a hot spot that the industry pays close attention to. As for the way to achieve deep decarbonization, Li Xinchuang analyzed that hydrogen smelting, oxygen blast furnace and non-blast furnace smelting are the key points.

Hydrogen smelting is an important technology for achieving zero-carbon emissions from fossil-free smelting in steel production. China Baowu, Hegang Group, etc. are carrying out related research. The realization of green hydrogen production and cost reduction are the key to breakthroughs in the application of this technology. Innovative R&D and application of low-carbon technologies such as carbon capture, utilization and storage are also very important. Shougang Group and Taiyuan Iron and Steel Group have carried out research on the application of carbon dioxide resources.

In 2020, HBIS Group will start the construction of the world's first hydrogen-rich gas direct reduction demonstration project in Zhangjiakou, and carry out innovative research and development from the entire process of distributed green energy utilization, low-cost hydrogen production, hydrogen direct reduction, and carbon dioxide removal.

The reporter learned from many sources that facing the new situation and tasks, the steel industry will increase the intensity of green and low-carbon investment, adhere to technological innovation, and coordinate the research and development of low-carbon technologies and low-carbon products. Editor/Xu Shengpeng

Comment

Praise

Praise

Collect

Collect

Comment

Comment

Search

Search

Write something~