- Bosch's new semiconductor manufacturing plant will start production ahead of schedule, with a total investment of 1 billion euros

The 1 billion euro factory will start producing chips for Bosch power tools in July, six months ahead of the original plan, and then start producing chips for the automotive industry in September 2021.

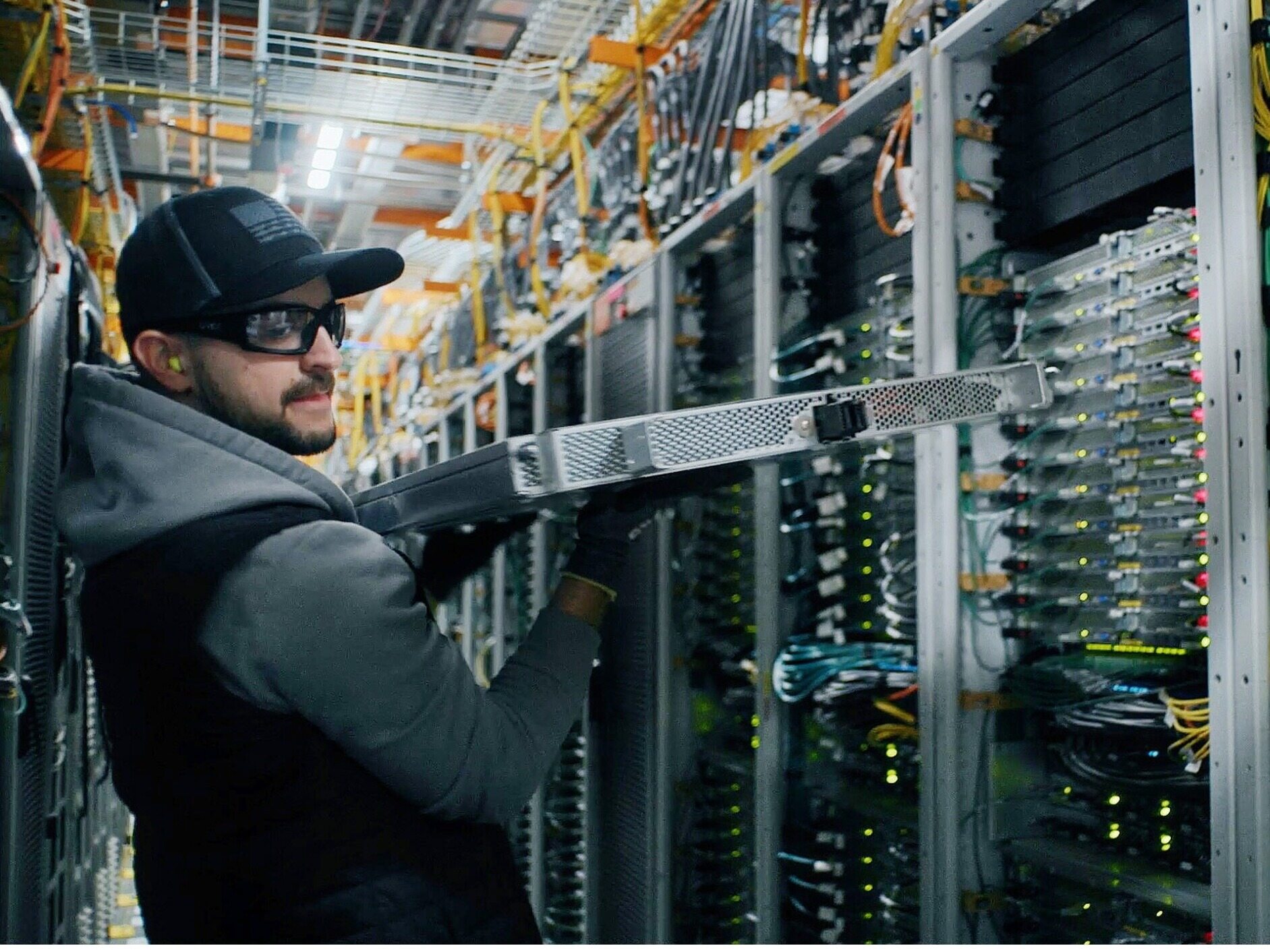

Dr. Volkmar Denner, Chairman of Robert Bosch GmbH's management committee, said that the new AIoT factory (combining the Internet of Things and artificial intelligence) provides Bosch with a fully connected, data-driven, and self-optimized manufacturing facility.

Semiconductor shortage hinders auto recovery

"Through artificial intelligence, we take production to a new level," Dr. Danner said at the opening ceremony. "In our Dresden plant, we will rely on the solutions provided by the Bosch Artificial Intelligence Center in the future: In the early stages, our artificial intelligence-based system can detect abnormalities and failures in the manufacturing process, accelerate the learning curve, and continue to improve Quality. Artificial intelligence is also used for production scheduling. It can guide wafers through up to 700 process steps on about 100 machines, saving time and money."

He continued: "In our factory, we have been collecting and checking data-these data are equivalent to 500 pages of text per second, or 42 million pages per day. Smart algorithms are used to evaluate these data in real time. This is also the fast speed of our new factory. The key to launching semiconductor production."

On-site maintenance will also benefit from artificial intelligence, whose algorithms can predict whether and when manufacturing machinery or robots need maintenance or adjustments. The use of data glasses and augmented reality technology will enable machine maintenance work to be carried out remotely, despite the travel restrictions associated with the coronavirus, this factor helps during the commissioning process.

The factory’s digital twin is composed of approximately 500,000 3D objects, including buildings and infrastructure, supply and disposal systems, cable ducts and ventilation systems, and machinery and production lines to support operations. According to Bosch, this capability allows it to simulate process optimization planning and retrofit work without interfering with ongoing operations.

The Dresden plant has a total of 250 employees, but it is expected to increase to about 700 in the next few years.

"Through this investment, we are strengthening Germany's position as a technological and industrial base," said Dr. Danner. "Only in the fabs in Reutlingen and Dresden, Bosch has invested more than 2.5 billion euros since the introduction of 200mm technology."Editor/Baohongying、design/zhangtao

Comment

Praise

Praise

Collect

Collect

Comment

Comment

Search

Search

Write something~