- After the completion of the Mawan Cross-Sea Passage, it will be of great significance to the external road network structure of Qianhai

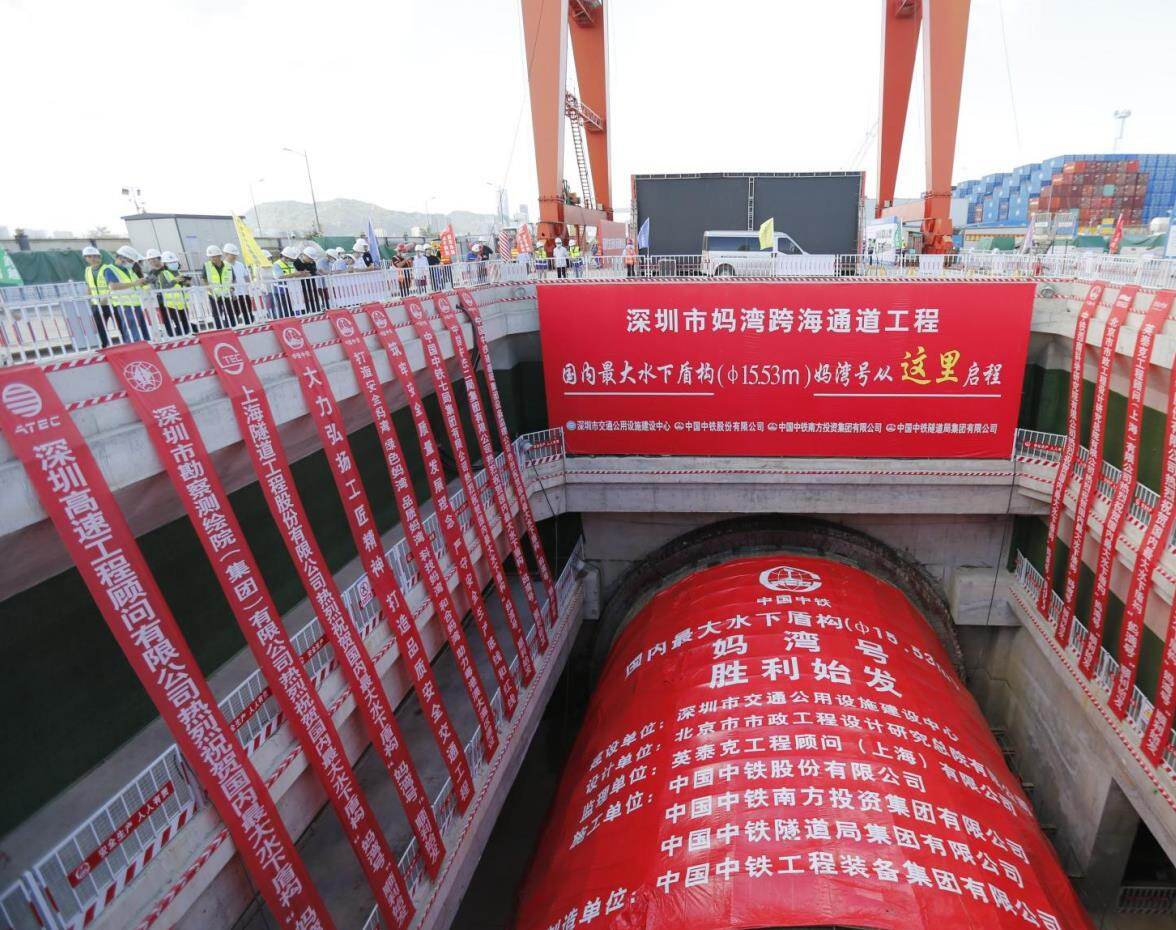

On July 15, 2021, along the Qianhai Bay in Shenzhen, as the "Mawan" shield machine started from the reclamation area of the Dachan Bay section, my country's largest underwater shield tunnel and Shenzhen's first cross-sea channel—— The Mawan cross-sea channel project has officially entered the shield construction stage.

Mawan Cross-sea Channel Project

The Mawan Cross-Sea Passage project was undertaken by Shenzhen Transportation Public Facilities Construction Center, China Railway South and China Railway Tunnel Bureau. The project starts at the intersection of Mawan Avenue and Yueliangwan Avenue in the Mawan Port area of Qianhai, and ends at the Dachanwan Toll Station and the intersection of Jinwan Avenue and Xixiang Avenue along the Yangtze River Expressway in Dachan Bay Area, Bao'an. The 8.05-kilometer channel is divided into two parts: surface roads and underground roads. The underground road is planned as an urban expressway with two-way six-lane roads and a design speed of 80 kilometers per hour; the surface road is planned as an urban main road with two-way six-lane roads and a design speed of 40 kilometers per hour.

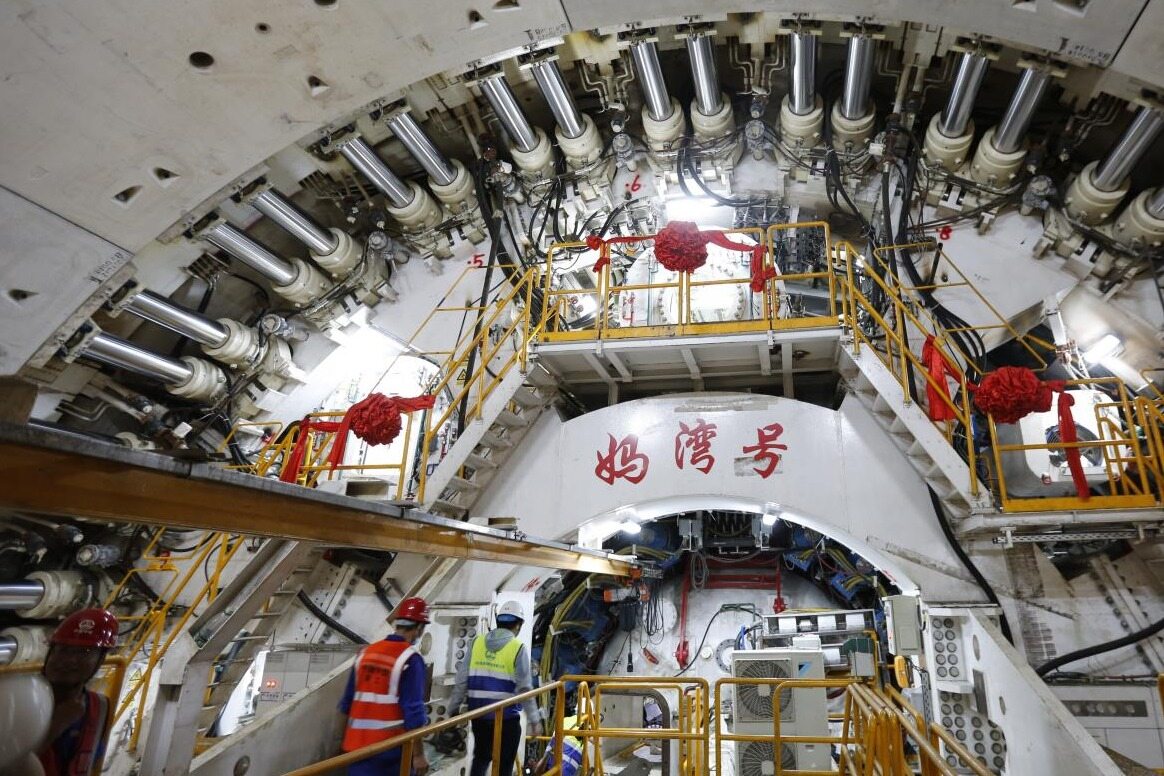

Zhao Yong, an engineer at the Shenzhen Transportation Public Facilities Construction Center, said that as the first large-diameter cross-sea shield tunnel in the Shenzhen Special Economic Zone, it links the port cargo transportation in the Nanshan Port Area and takes into account the connectivity of the Mawan, Chiwan and Dachan Bay areas. Passenger transportation, realize the separation of passenger and cargo and transit separation in Qianhai area, realize the expansion and integration of urban development space, and play a positive role in promoting the transportation interconnection of the Guangdong-Hong Kong-Macao Greater Bay Area. Shield machine is a kind of special engineering machinery for tunnel boring, and it is a major complete set of high-tech equipment. The "Mawan" air-cushioned mud-water balance shield machine is tailor-made and independently designed and manufactured by China Railway Group according to the engineering geological conditions. It has a diameter of 15.53 meters and a height of more than 5 floors. The main components are 140 meters in length and weigh 4650 tons. The excavation section is 6 times that of a conventional subway shield.

The shield section of the Mawan Cross-sea Channel is 2063 meters long. There are many difficulties in the tunneling process: "Long": the equipment travels through high-strength rock formations for a long distance, and there are more than 1 km of uneven soft and hard rock formations on the propulsion line. 700 meters is the total length. Hard rock formations in cross-section have a lot of wear on the shield machine tools; "difficult": crossing the complex terrain of the seabed will easily cause the shield machine to float up and deviate from the preset trajectory. There are problems such as high tool wear and high risk of tool change, and the construction is more difficult. Large; "Deep": Mawan Subsea Tunnel is located at a depth of more than 40 meters underwater, with a maximum water pressure of 5bar and a rock strength of up to 193MPa; "Large": Mawan Tunnel has a large cross-section and the outer diameter of the segment exceeds 15 meters. The performance and construction technology requirements are extremely high. In view of the difficulties and risks of project construction, the "Mawan" shield machine adopted a number of targeted technological innovations. Install wear detection equipment to detect tool wear to fully guarantee safety during construction; main drive belt swing function overcomes the impact of full-section hard rock and upper soft and lower hard strata jammed shells; use of crushing device, air cushion direct excavation mode, Large flow flushing system design, etc. to solve the problem of blockage and stagnation.

At the same time, in order to ensure the sealing and safety of the tunneling construction in high water pressure formations, the project team adopted the design of 4 outer seals + 4 inner seals, the drive box has the pressurization capacity, and the shield tail is equipped with 5 shield tail brushes. For the tunneling of shallow soil layers, a four-circuit pressure holding system is also designed to ensure the smooth progress of shield tunneling. Wang Binbin, chief engineer of the Mawan Sea Crossing Project of China Railway Tunnel Bureau, introduced that in order to deal with the construction problems in the dumping and reclamation area, the project innovatively applied DJP cement-soil composite pipe pile technology during the construction of the foundation pit, and used the digital Beidou positioning system and satellite positioning during the construction. , BIM and other advanced technologies, comprehensively perceive road and infrastructure construction, and conduct real-time online monitoring. "This has changed the traditional construction methods of manual supervision and artificial lofting in the past, and the construction accuracy and monitoring efficiency have been greatly improved."

Keywords: engineering news, engineering construction

From the start of the project in July 2019, to the production of the "Mawan" in Shunde, Foshan on January 8, 2021, to the successful launch of the shield machine on July 15, the builders used large Data, cloud storage, 5G informatization and other technologies can upload data to the State Key Laboratory of Shield Tunneling and Tunneling Technology in real time to provide strong technical support for on-site tunneling. Editor/Xing Wentao

Comment

Praise

Praise

Collect

Collect

Comment

Comment

Search

Search

Write something~