- From roads, railways, to bridges, stunning the world, China really can bear the title of infrastructure madman

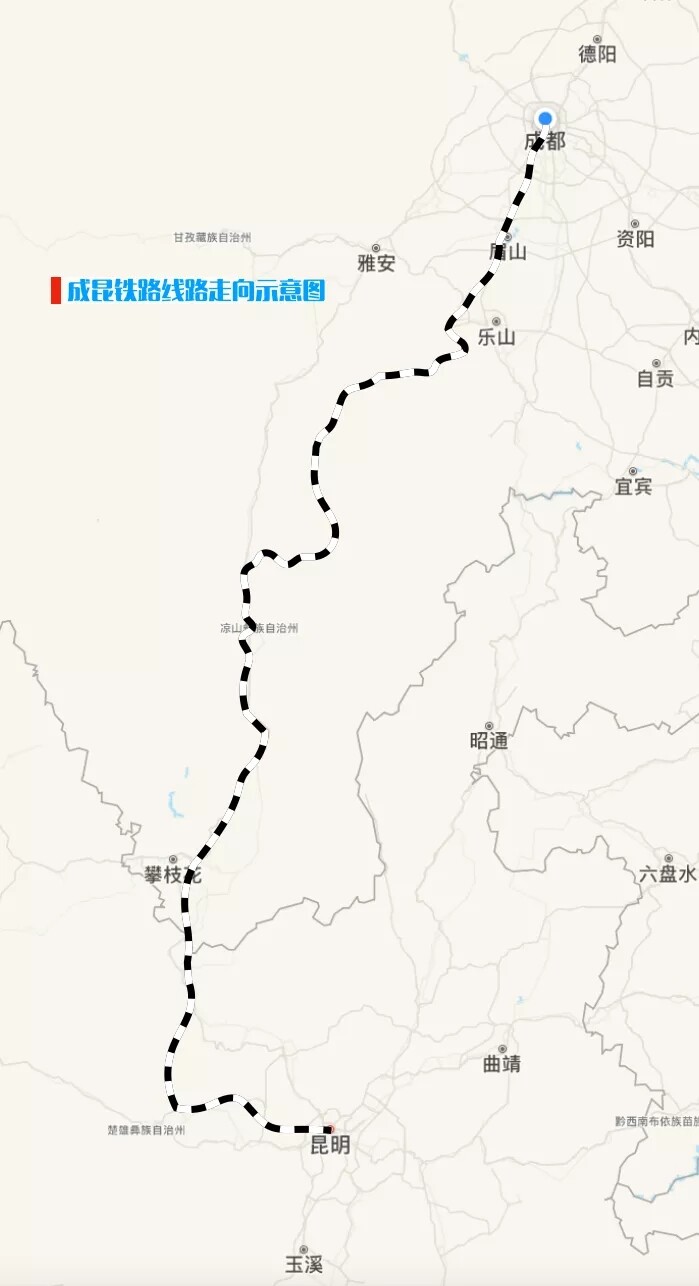

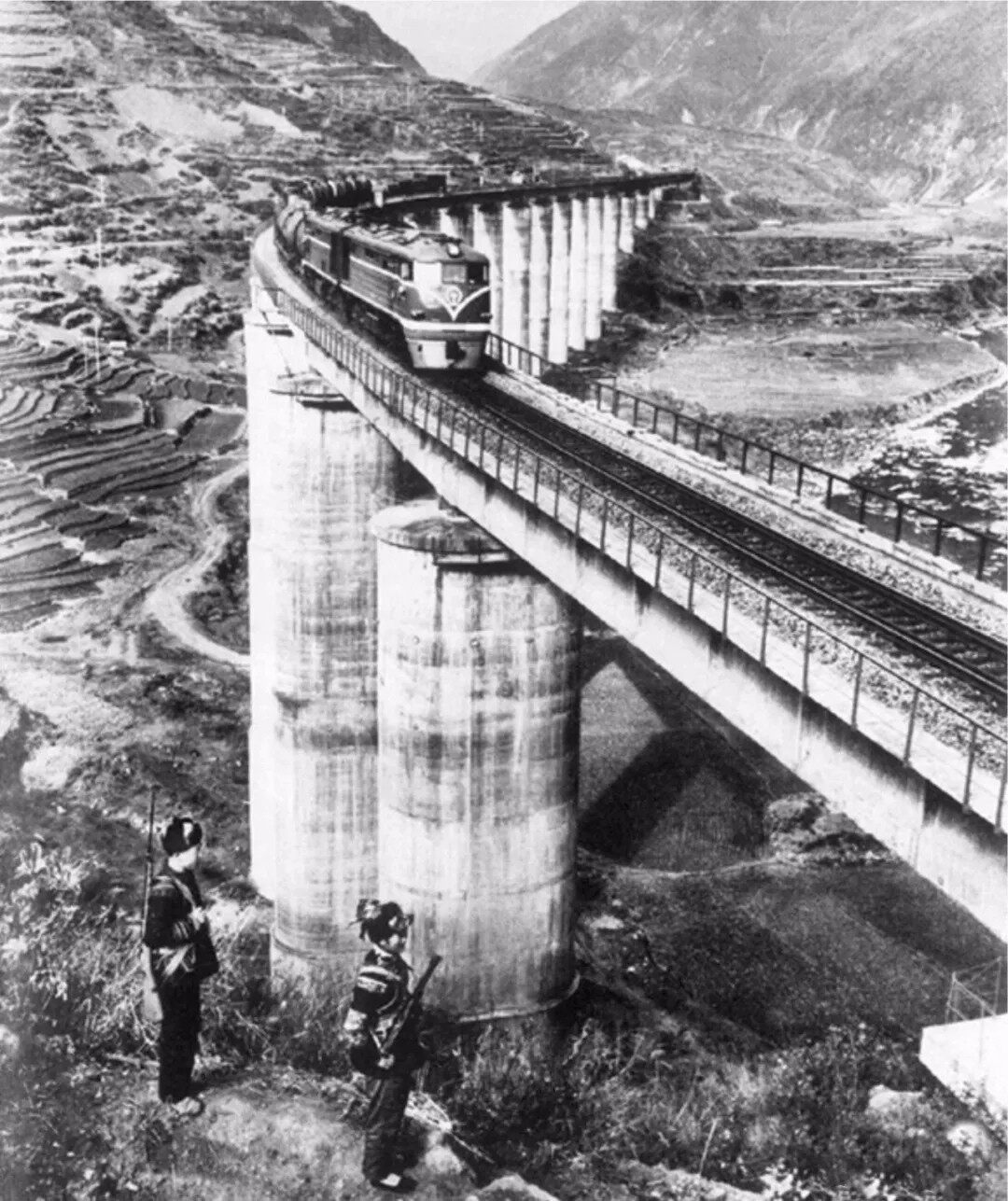

The difficulty of Shu Road is harder to go to the sky! In July 1970, the Chengdu-Kunming Railway, which broke through the difficult shackles of the Shu Road and carried the efforts of 300,000 people, was officially opened to traffic. While shocking the world, it also opened the way for the growth of China's infrastructure madness.

Road to Miracle Cheng-Kun Railway

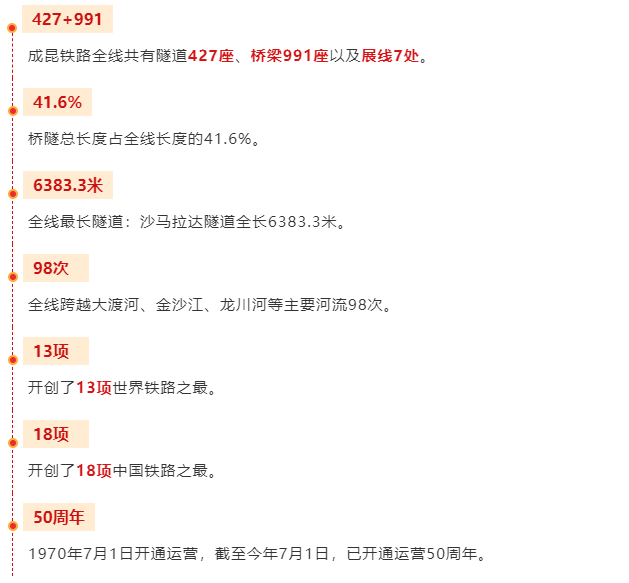

The total length of the Chengdu-Kunming Railway is 1,096 kilometers, starting from the Chengdu Plain at an altitude of about 500 meters, going up against the Dadu River and Niuri River, passing through the Shamarada Tunnel at an altitude of 2,280 meters, along the Sunshui River, Anning River, and Yalong River, down to the altitude The Jinsha River Gorge at about 1,000 meters, and the Longchuan River ascends to the Central Yunnan Plateau at an altitude of about 1,900 meters. More than 500 kilometers are located in the area of 7-9 degrees earthquake intensity.

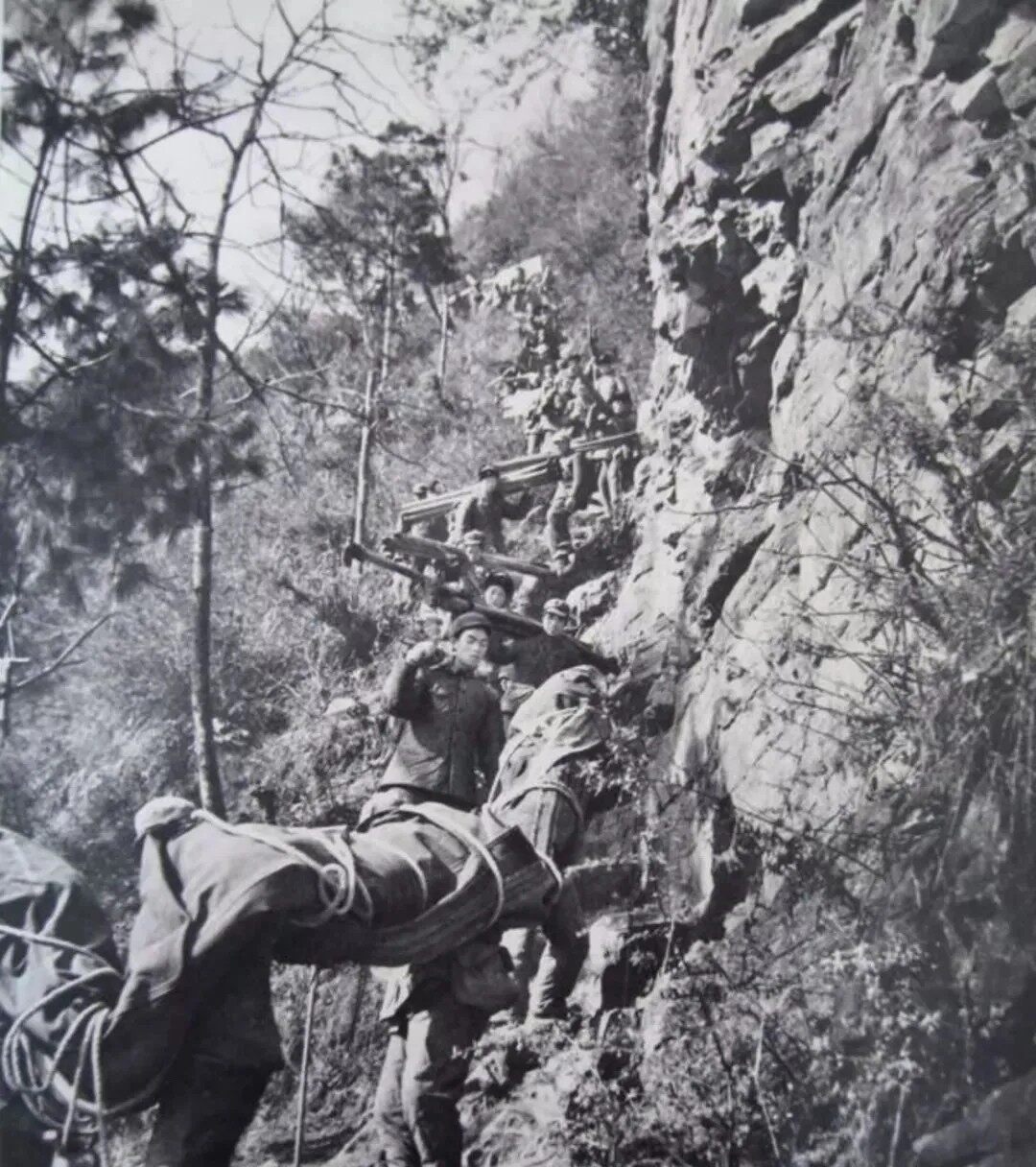

The mountains along the route are steep, with strange peaks towering, deep and dense, ravines are vertical and horizontal, and the topography and geology are extremely complex. From the Sichuan Basin to the Yunnan-Guizhou Plateau, crossing the complex mountainous area known as the “geological museum” is regarded by foreigners as a “life forbidden zone”.

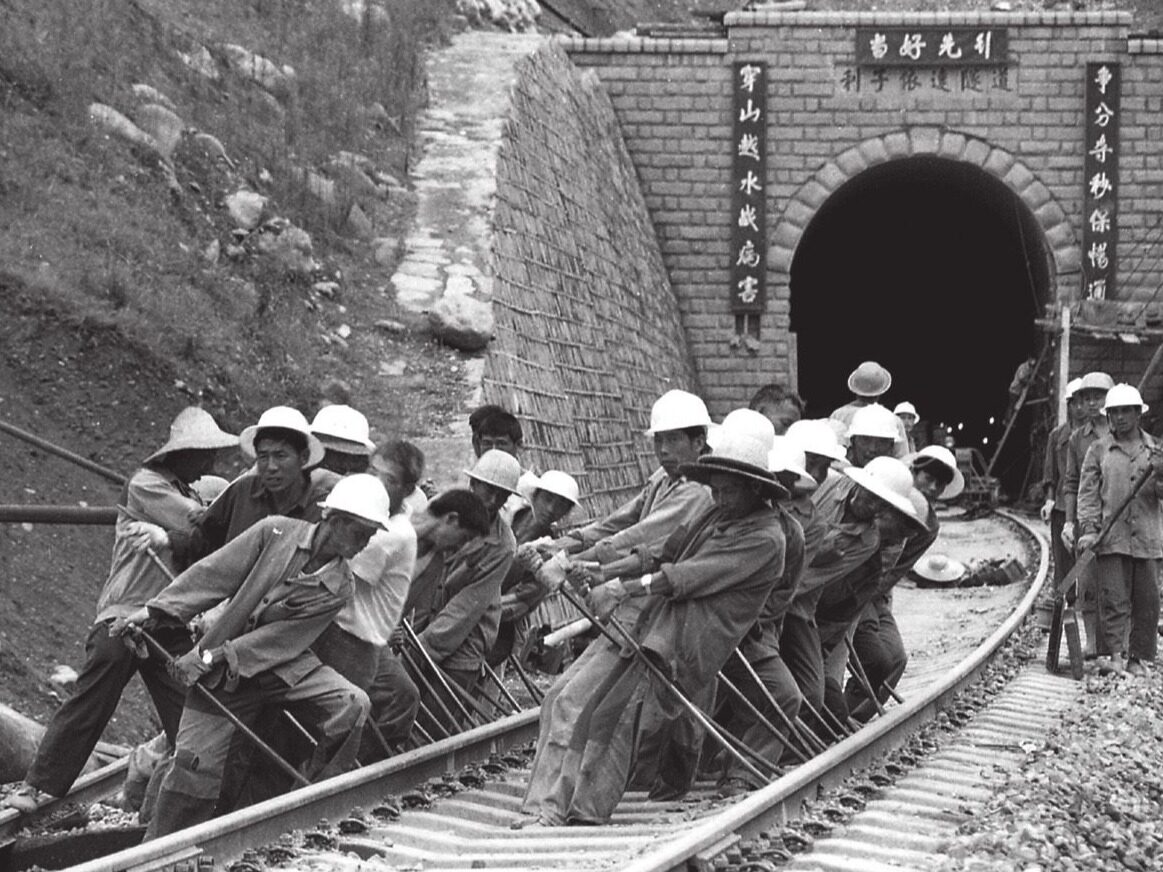

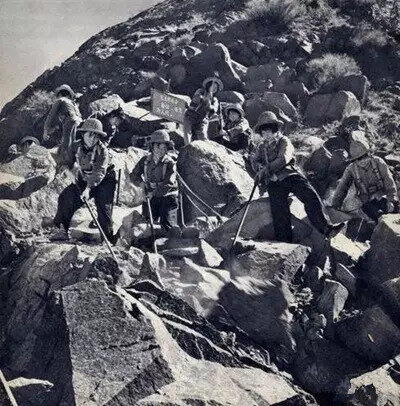

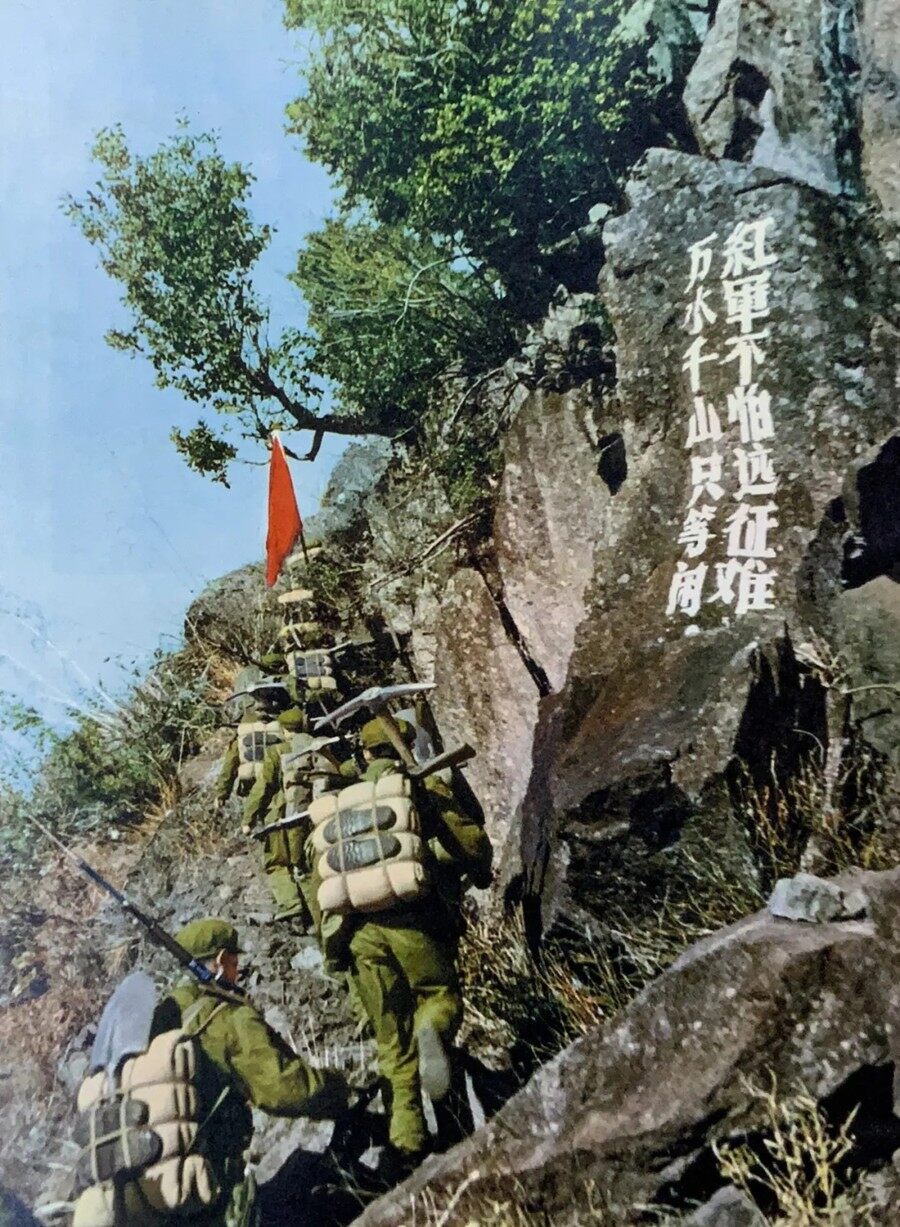

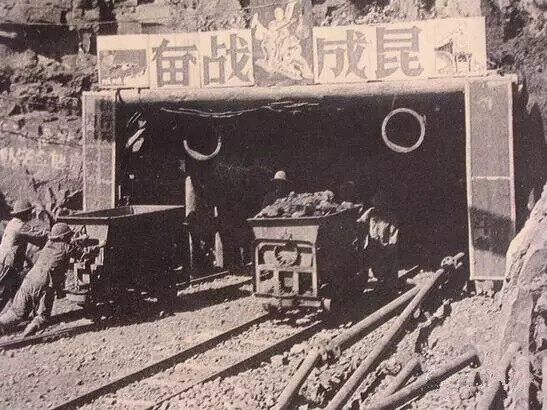

It is reported that on July 1, 1958, the Chengdu-Kunming Railway (Chengdu-Emei section) was fully started. Faced with extreme challenges, a road-building army composed of more than 300,000 Chinese The construction of the Chengdu-Kunming Railway started the grand battle for the construction of the Chengdu-Kunming Railway.

From 1958 to 1970, more than 10 years of hard work and more than 2,000 people sacrificed. The Chinese used their own technology and their own team to open up this Sichuan-Yunnan corridor, leaving behind the "Chengkun Spirit" that is full of color in the history of railways.

In July 1970, the Chengdu-Kunming Railway was completed and opened to traffic. It not only composes a magnificent poem in the history of New China’s railways, but also breaks through many railways in China and the world’s railways at that time. It also created a miracle in the history of railway construction in the world. The returned moon rock and the Soviet Union’s first man-made earth satellite were called by the United Nations as "the three miracles symbolizing the conquest of nature by mankind in the twentieth century."

From 1970 to the present, for half a century of operation, the Chengdu-Kunming Railway has continued unabated and the legend continues. Connect the isolated stockades to the outside world, keep up with the pace of development, let children and special agricultural products go out of the mountains, and let the poverty alleviation teams go into the mountainous areas.

With the indomitable spirit of a batch of frontline soldiers and workers, China’s infrastructure madness has been consolidated step by step, but it is also different from relying on steel and hammers to dig step by step. Now we are not only willing to endure hardships, have courage, but also Have wisdom and strategy.

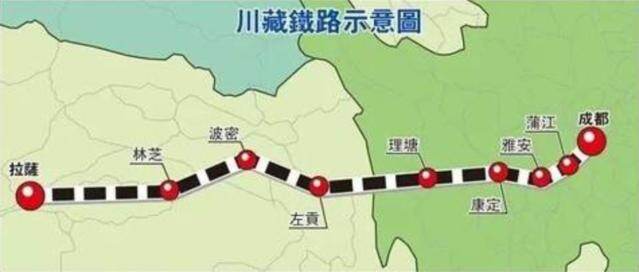

The Sichuan-Tibet Railway

The entire Sichuan-Tibet Railway is about 1800km long. It starts from Chengdu, Sichuan Province in the east, and passes through Ya'an, Kangding, Qamdo, and Linzhi to Lhasa, Tibet. The Chengya section (Chengdu-Ya'an) and Lalin section (Lhasa-Nyingchi) are currently under construction. The Linzhi section has already carried out survey, design and research work. Western experts who came to the Sichuan-Tibet area to inspect railway construction once asserted that the Sichuan-Tibet Railway will take 100 years to complete. From the official start of construction in 2014 to the expected full-line opening in 2026, China will only need 12 years to complete the construction.

This railway with an investment of hundreds of billions can be regarded as an epic-level project in China. Its construction difficulty is also rare in the world. However, the 1,800-meter-long line has experienced eight ups and downs, with a cumulative climbing height of more than 14,000 meters, which is equivalent to the most difficult and dangerous railway. , Building the world’s most technically difficult "giant roller coaster" between the most complex mountains and valleys.

Hong Kong-Zhuhai-Macao Bridge

On October 23, 2018, the Hong Kong-Zhuhai-Macao Bridge was officially opened. China once again used a miracle bridge to create many of the world's best:

The longest sea-crossing bridge: The Hong Kong-Zhuhai-Macao Bridge is 55 kilometers in length and is currently the world's longest sea-crossing bridge.

The longest steel bridge: 15 kilometers of the Hong Kong-Zhuhai-Macao Bridge is an all-steel structure steel box girder, which is currently the world's longest steel bridge.

The longest submarine tunnel: The submarine immersed tube tunnel of the Hong Kong-Zhuhai-Macao Bridge has a total length of 6.7 kilometers.

The largest immersed tube tunnel: standard immersed tube tunnels, each section is 180 meters long and has a displacement of more than 75,000 tons.

The most accurate deep-sea kiss: The immersed tube is used for unmanned docking at a depth ranging from 13 meters to 48 meters below sea level, and the docking error is controlled within 2 cm.

The deepest immersed tube tunnel: The deepest part of the Hong Kong-Zhuhai-Macao Bridge undersea tunnel is 48 meters under the sea. At present, the deepest immersed tube tunnel in the world rarely exceeds 45 meters.

The amount of steel used for the bridge is equivalent to 60 Eiffel Towers, and it can withstand a magnitude 8 earthquake, which is equivalent to the Wenchuan earthquake that can be unharmed. It can withstand more than 16 typhoons, and a 10 typhoon uproots the tree. It is also 20 years longer than other domestic bridges and has a service life of up to 120 years.

High-speed Maglev Transportation System

On July 20, 2021, China’s 600 km/h high-speed maglev transportation system developed by CRRC and with completely independent intellectual property rights was successfully rolled off the assembly line in Qingdao. This is the world’s first high-speed maglev transportation system designed to reach 600 km/h. It marks that China has mastered the complete set of high-speed maglev technology and engineering capabilities.

The project was launched in October 2016, a test prototype was developed in 2019, and it was successfully tested on the test line of Tongji University in Shanghai in June 2020. After system optimization, the final technical plan was determined, and a complete system was developed in January 2021. And started a six-month joint debugging and joint test. So far, after 5 years of research, the 600 kilometers per hour high-speed maglev transportation system was officially rolled off the assembly line, successfully overcoming various technical difficulties.

Its successful development is of great and far-reaching significance for building a new engine for China's high-end equipment industry, forming new advantages for rail transit, seizing the commanding heights of technological competition, accelerating the construction of a modern comprehensive three-dimensional transportation network, and supporting the strategy of being a powerful country in science and technology and a powerful country in transportation.

China's construction speed: Huoshen Mountain, Thunder Mountain, Fangcai Hospital.

The mileage of expressways opened to traffic reached 131,000 kilometers, ranking first in the world.

There are 347,000 high-rise buildings in China, and more than 6,000 super high-rise buildings above 100 meters, ranking first in the world in terms of number.

The coverage of China's communication base stations is more than 5 million, which is more than 20 times that of the United States and the number one in the world.

From the Sichuan-Tibet railway project to the Hong Kong-Zhuhai-Macao Bridge infrastructure project, from China's high-speed rail to pull one industrial base, to the pioneers of China's nuclear industry chain, and then from the sky aerospace to deep-sea submarine testing, major equipment core enterprises support Because of China's independent innovation in dozens of high-end equipment industries such as aerospace, shipbuilding, machinery and automobiles, non-ferrous metallurgy, basic parts, profiles, precision instruments, and the realization of advanced industrial foundations and industrial chain modernization, non-equipment manufacturing cannot be competent. Editor/He Yuting

Comment

Praise

Praise

Collect

Collect

Comment

Comment

Search

Search

Write something~